Longhe has been focusing on plastic

machinery for 36+ years

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Longhe

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

750x610x1200mm

-

Power (kW):

-

4

-

Weight (T):

-

0.3

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

plastic recycling crusher machine

-

Type:

-

Single Shaft

-

Usage:

-

Waste Plastic Shredding

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Pe Pp Plastic Shredder Machine

-

Certification:

-

ISO9001 and CE

-

Marketing Type:

-

Hot Product

Quick Details

-

Max.Production Capacity (kg/h):

-

100

-

Place of Origin:

-

Guangdong, China

-

Production Capacity (kg/h):

-

80 - 100 kg/h

-

Brand Name:

-

Longhe

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

750x610x1200mm

-

Power (kW):

-

4

-

Weight (T):

-

0.3

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

plastic recycling crusher machine

-

Type:

-

Single Shaft

-

Usage:

-

Waste Plastic Shredding

-

Application:

-

Recycle Waste Plastic

-

Keyword:

-

Pe Pp Plastic Shredder Machine

-

Certification:

-

ISO9001 and CE

-

Marketing Type:

-

Hot Product

FOCUS ON MANUFACTURING

1988

FOUNDED IN 1988

35000m²

FACTORY FLOOR AREA

36+

YEARS EXPERIENCE

MORE THAN 15 YEARS OF SENIOR

TECHNICAL TEAM

Longhe enterprises focus on supporting advanced equipment and pay more attention to talent training, with an average time in Longhe more than 15 years of professional technical service team

Professional technology focus

on research and development

Factory environment · Live shooting

OVER 150000+ CUSTOMERS

IN 36+ YEARS CHOOSE Longhe

Product Description

POWERFUL CRUSHER

More than 50 kinds of materials broken

MODEL:PC180

Product Paramenters

Consult customer service for more enhanced high-power models

|

model

|

diameter of crushing chamber (mm)

|

crushing capacity (kg/h)

|

motor power (kw)

|

fixing blade (pcs)

|

movable blade (pcs)

|

Dimension size (mm)

|

||||||

|

PC180A

|

190*165

|

30-80

|

2.2

|

2

|

9

|

650*530*980

|

||||||

|

PC230A

|

210*235

|

50-110

|

4

|

2

|

6

|

750*610*1200

|

||||||

|

PC300A

|

310*245

|

100-250

|

5.5

|

2

|

9

|

900*760*1200

|

||||||

|

PC400A

|

410*260

|

200-450

|

7.5

|

2

|

12

|

950*860*1300

|

||||||

|

PC500A

|

510*285

|

360-720

|

11

|

4

|

15

|

1110*970*1450

|

||||||

|

PC600A

|

610*285

|

470-870

|

15

|

4

|

18

|

1110*1070*1450

|

||||||

|

Models above PC600A have wheels

|

|

|

|

|

|

|

||||||

|

PC700B

|

710*360

|

550-950

|

22

|

4

|

21

|

1500*1250*1900

|

||||||

|

PC800B

|

810*380

|

800-1000

|

30/37.5

|

4

|

6/15

|

1700*1410*2250

|

||||||

|

PC1000CA

|

1020*810

|

1000-1300

|

75

|

4

|

9/18

|

2000*1980*2650

|

||||||

|

PC1500

|

1500*610

|

2000-3000

|

75

|

4

|

15

|

2000*2480*2680

|

||||||

Application Range

WIDE USES

Suitable for PC, PP material, sheet material, tube material, cardboard, boxes, mineral bottles, material heads....

VIDEO SHOWS

CRUSHING EFFECT

ON-SITE CRUSHING EFFECT

Before and after crushing

CRUSHER 9 ADVANTAGES

Longhe refuses to use shoddy products and strictly control the standards

|

Crusher manufacturing details

|

|

1. Multi-layer reinforcement of machine stress points

|

|

2. Increase the size of the crushing chamber

|

|

3. Pure red copper motor

|

|

4. 5inch large steel wheels

|

|

5. dust-removal design function inside the machine

|

|

6. The crusher screen has a high fit and does not hide

materials |

|

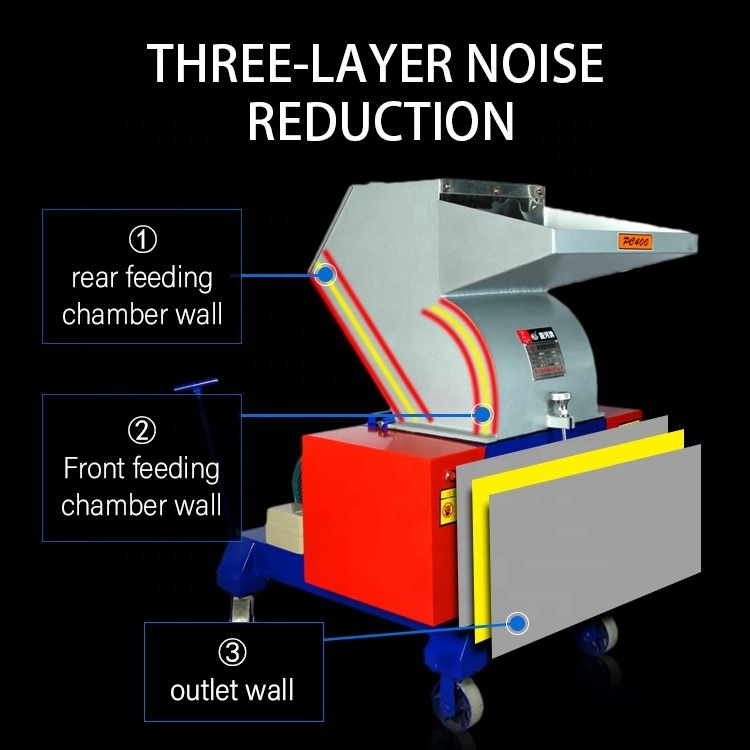

7. 3-layer sound-insulation design

|

|

8. Blades are durable

|

|

9. The storage hopper capacity is extended by 30 cm

|

Crusher blade

extremely sharp

The blade is made of imported steel from Japan

3 TYPES OF BLADE

TO CHOOSE FROM

Different materials, different knife types, better effect

1

FLAT KNIFE

thick, hard, brittle, lumpy

Wood/Leftovers/rubber/Herbs and Spices/Cup lid, etc.

2

BLADE KNIFE

Strong ductility, thin, sheet, strip

Packaging bag/latex/sponge/

bottle/bucket/can

3

CLAW KNIFE

THREE-LAYER NOISER EDUCTION DESIGN

Three layers of sound insulation at three positions, stronger noise reduction

Machine detail

Always insist on good quality

details determine success or failure

The better the material, the longer the life, the larger the size, the stronger the load-bearing

Strong pressure resistance

very durable

The size of the discharge depends on the size of the screen mesh, and the choice is more flexible

Joint welding reinforcement, sufficient material, no cutting corners

Machine maintenance

|

component

|

|

Maintenance method

|

|

|

|||

|

Silicone Parts

|

|

Regular replacement

|

|

|

|||

|

Lock knife screw spring washer

|

|

Wear and tear should be replaced in time

|

|

|

|||

|

Lock knife screw

|

|

Wear and tear should be replaced in time

|

|

|

|||

|

screw

|

|

Add oil and tighten

|

|

|

|||

|

Safety switch

|

|

Safety switch at the same height as the cushion

|

|

|

|||

|

Blades

|

|

Sand regularly and adjust distance to standard

|

|

|

|||

|

Bearing dust outlet

|

|

Regularly clean the impurities in the discharge ports on both sides

|

|

|

|||

|

Crusher Belt

|

|

Regularly adjust the tightness and check the degree of wear and tear and replace it in time

|

|

|

|||

|

Screw hole

|

|

Add oil and keep debris free

|

|

|

|||

|

Sieve net

|

|

After running for 1440 hours, check the degree of wear and tear and replace it in time

|

|

|

|||

|

Bearings

|

|

Add lubricating oil regularly

|

|

|

|||

|

|

|

After turning on the machine, run it empty to see if there is any abnormal noise or rotation direction Is it correct? Make sure

that there is no problem before starting production |

|

|

|||

|

Long downtime

|

|

Long periods of downtime require cleaning and oiling of the blades.When using it again, run the machine empty first, and then use the scrap to remove the oil on the blade several times before it can be used normally.

|

|

|

|||

Hot Searches