- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2800 KG, 1.5-14.5t

-

Marketing Type:

-

New Product

-

Max feeding size:

-

25-500mm

-

Discharge size:

-

1-150mm

-

Capacity:

-

5-220t/h

-

Motor power:

-

5.5-132kw

-

Yield:

-

5-200t

-

Product name:

-

roller crusher

-

Application:

-

stone crushing

-

Advantage:

-

High Efficiency Low Energy

Quick Details

-

Capacity(t/h):

-

5-220t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RD

-

Weight:

-

2800 KG, 1.5-14.5t

-

Marketing Type:

-

New Product

-

Max feeding size:

-

25-500mm

-

Discharge size:

-

1-150mm

-

Capacity:

-

5-220t/h

-

Motor power:

-

5.5-132kw

-

Yield:

-

5-200t

-

Product name:

-

roller crusher

-

Application:

-

stone crushing

-

Advantage:

-

High Efficiency Low Energy

Products Description

The Roller Crusher, also known as the double roller crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials,and chemical materials.

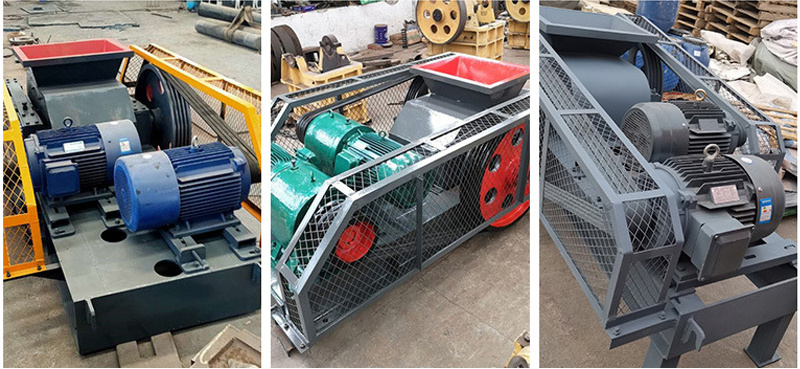

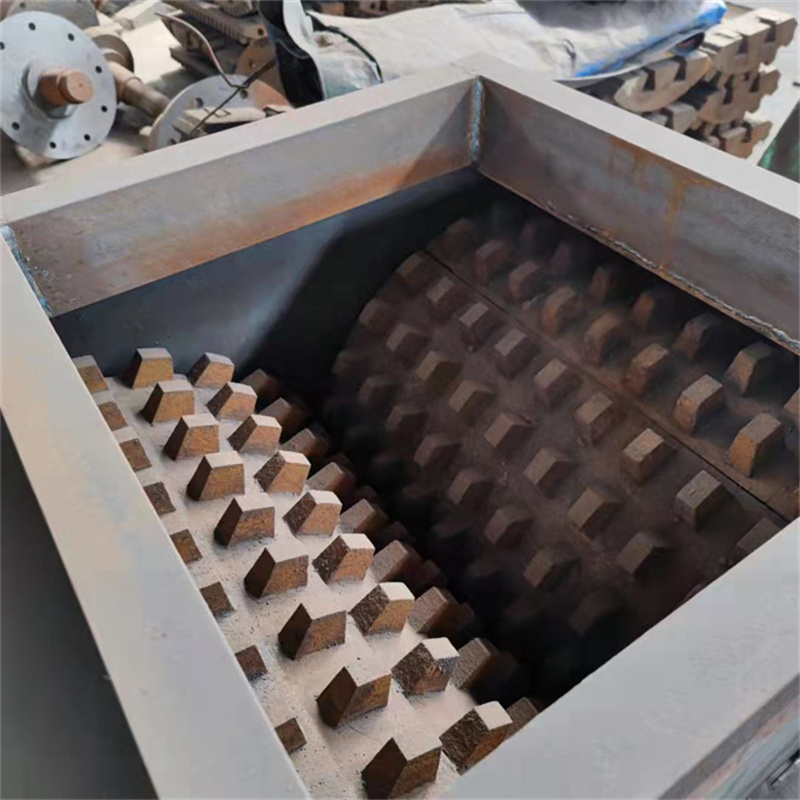

Details Images

Working Principle

The driving mechanism of roller crusher is composed of two motors, which are transferred to the groove wheel through the triangle belt to drive the roller and rotate in the relative direction, so that the material is squeezed and broken.

There are two cylindrical rollers horizontally installing on mutually parallel racks, where one of the roller bearing is movable

and the other roller bearing is fixed. Driven by electric motor, the two rollers do opposite rotation, which produces downward acting force to crush materials between two crushing rollers; broken materials that are in line with the required size are pushed out by roller and discharged from the discharging port.

and the other roller bearing is fixed. Driven by electric motor, the two rollers do opposite rotation, which produces downward acting force to crush materials between two crushing rollers; broken materials that are in line with the required size are pushed out by roller and discharged from the discharging port.

Product Paramenters

Advantages

Application of Roller Crusher

The roller crusher has widely application in the industries of mining, building materials, chemical industry, metallurgy, etc. The roller crusher can do secondary and fine crushing of materials with middle hardness or middle minus hardness, such as mineral,rocks, coke, coal, slag, etc.River pebble, Calcite, quartzite, marble, cobble, bentonite, iron ore, bluestone, mountain stone,water slag, limestone, weathered sand, granite, basalt. Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc

Hot Searches