2.We will send the instruction book to you to let you install the machine. You can talk with our engineer by video chat or we will send the engineers overseas to help you.

- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WATON

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

300*180*240

-

Hollow part volume:

-

50~2000 ml

-

Power (kW):

-

25

-

Weight (KG):

-

2500 KG

-

Model Number:

-

ECO-2L

-

Suitable bottle:

-

Water bottle/juice bottle/drink bottle/oil bottle

-

Processing Type:

-

Stretch Blowing

-

Color:

-

Blue+gray

-

Cavity:

-

2

-

Free Service:

-

Bottle Drawing

-

Customer's requipment:

-

Bottle Samples

-

After-sales Service:

-

24 Hours Online Service

-

OEM/ODM service:

-

Yes

-

Port:

-

Ningbo

Quick Details

-

Neck Diameter(mm):

-

38 mm

-

Max.Bottle Diameter(mm):

-

114.3 mm

-

Max.Bottle Height(mm):

-

330 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WATON

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

300*180*240

-

Hollow part volume:

-

50~2000 ml

-

Power (kW):

-

25

-

Weight (KG):

-

2500 KG

-

Model Number:

-

ECO-2L

-

Suitable bottle:

-

Water bottle/juice bottle/drink bottle/oil bottle

-

Processing Type:

-

Stretch Blowing

-

Color:

-

Blue+gray

-

Cavity:

-

2

-

Free Service:

-

Bottle Drawing

-

Customer's requipment:

-

Bottle Samples

-

After-sales Service:

-

24 Hours Online Service

-

OEM/ODM service:

-

Yes

-

Port:

-

Ningbo

Product Description

|

Models

|

ECO-2L

|

|

Theoretical Capacity

|

1800-2400BPH

|

|

Mold Cavities

|

2

|

|

Neck Size

|

18-38mm

|

|

Max. Volume

|

2000ml

|

|

Advantages

|

High productivity; easy to operate; long time after-sale service.

|

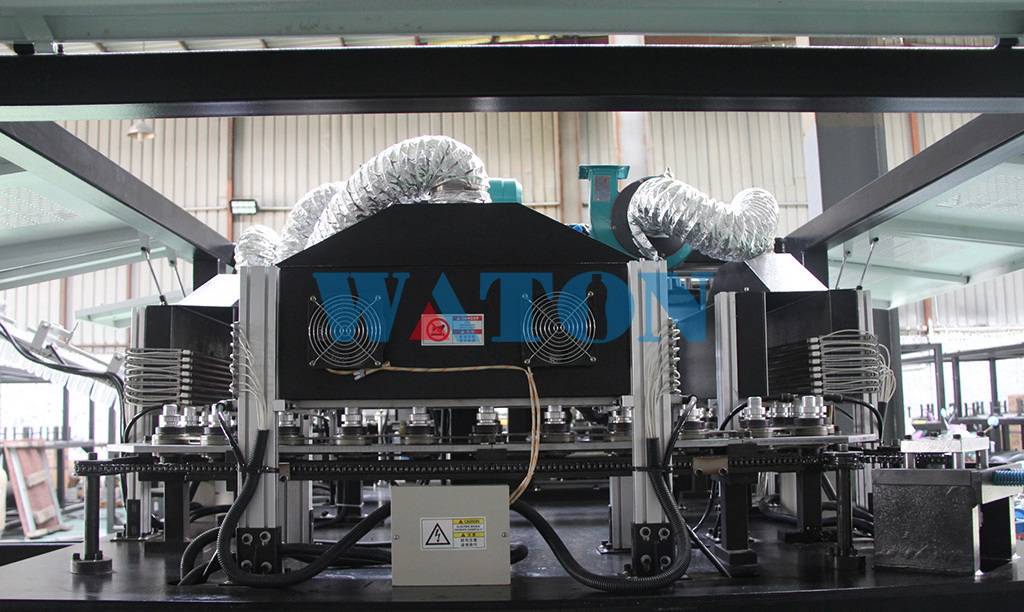

Model ECO-2L Automatic Stretch-blow Machine is newly designed and reformed on previous experience of our manufacture. Main feature of this model:

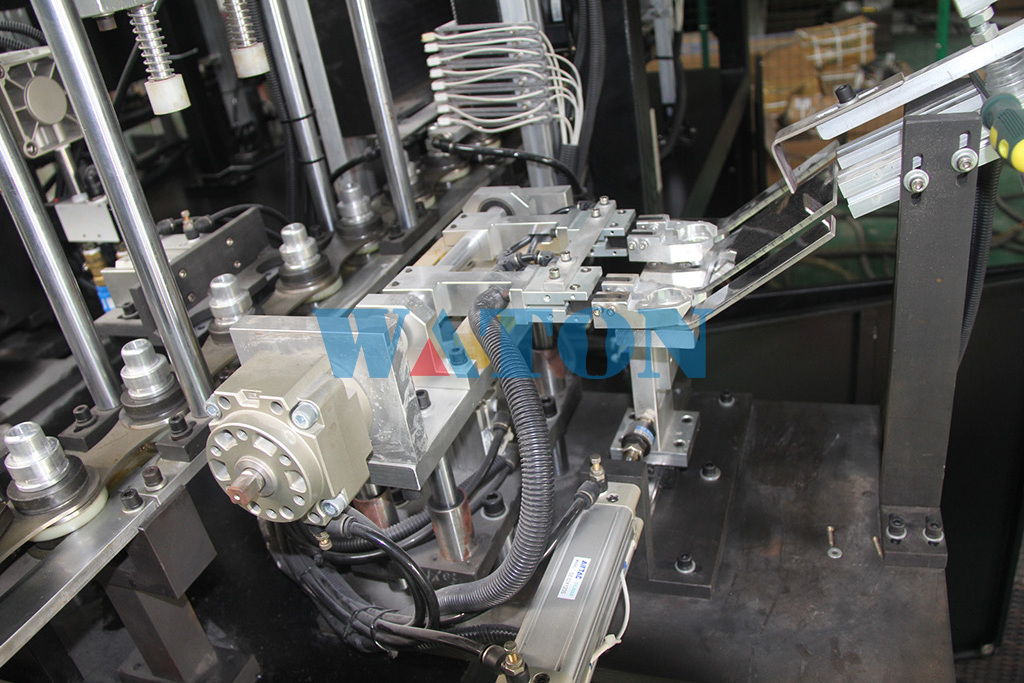

1.Servo motor controls the preform stepping motion;

2.Compact with 2 cavities, center distance 139.7mm;

3.Newly high efficiency Ruby Heaters;

4.It is an ideal equipment to make different-shaped containers, such as mineral water bottle, beverage bottle, cosmetics bottle, medicine bottle, pesticide bottle, edible-oil bottle, wine bottle, milk bottle, etc.

With reasonable investment and high efficiency, it helps you raise production and

save energy.

Direction for use

1.We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

WATON Machinery designs the most suitable machine models according to the special requirements of customers, suitable for PET containers from 200ml~20L, including package for water, Carbonated Soft Drink, juice, milk, edible oil, beer, solid food, cosmetics, pharmaceuticals, etc.

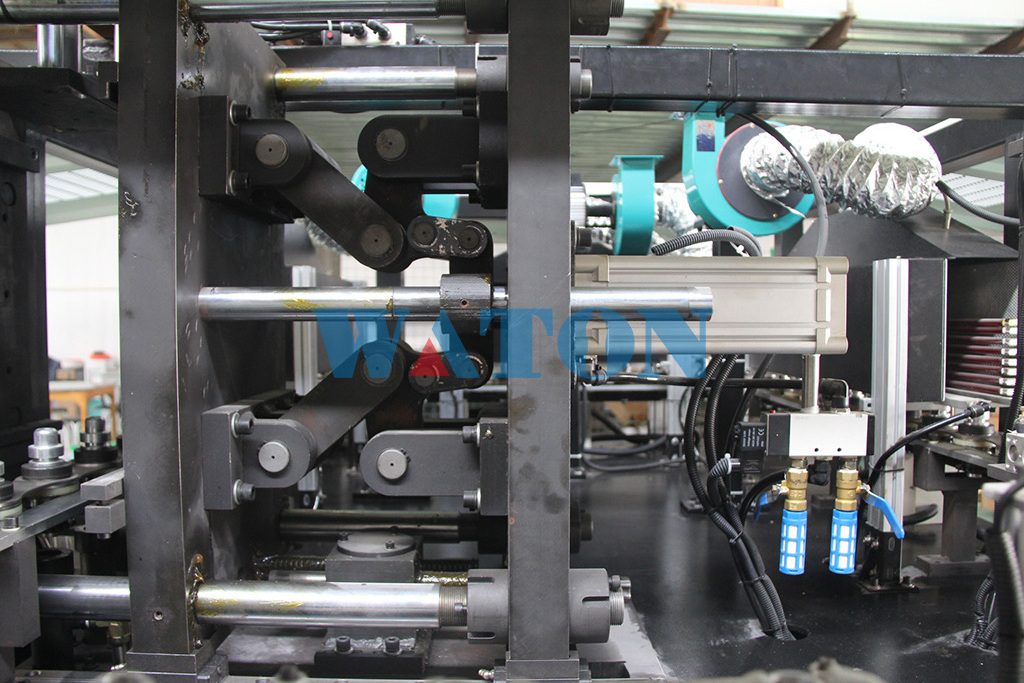

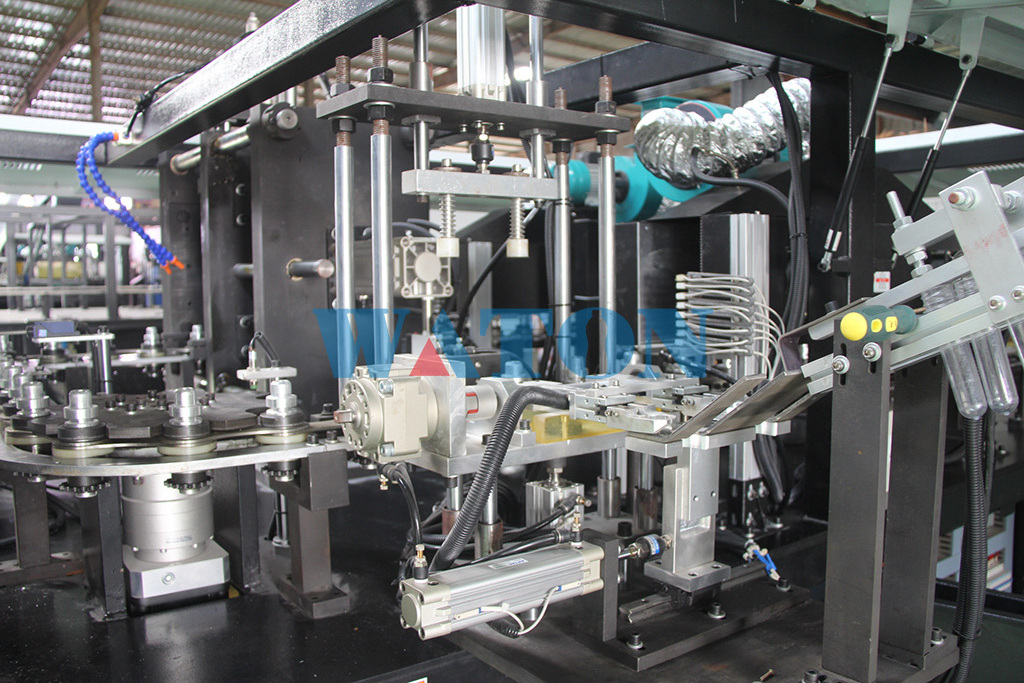

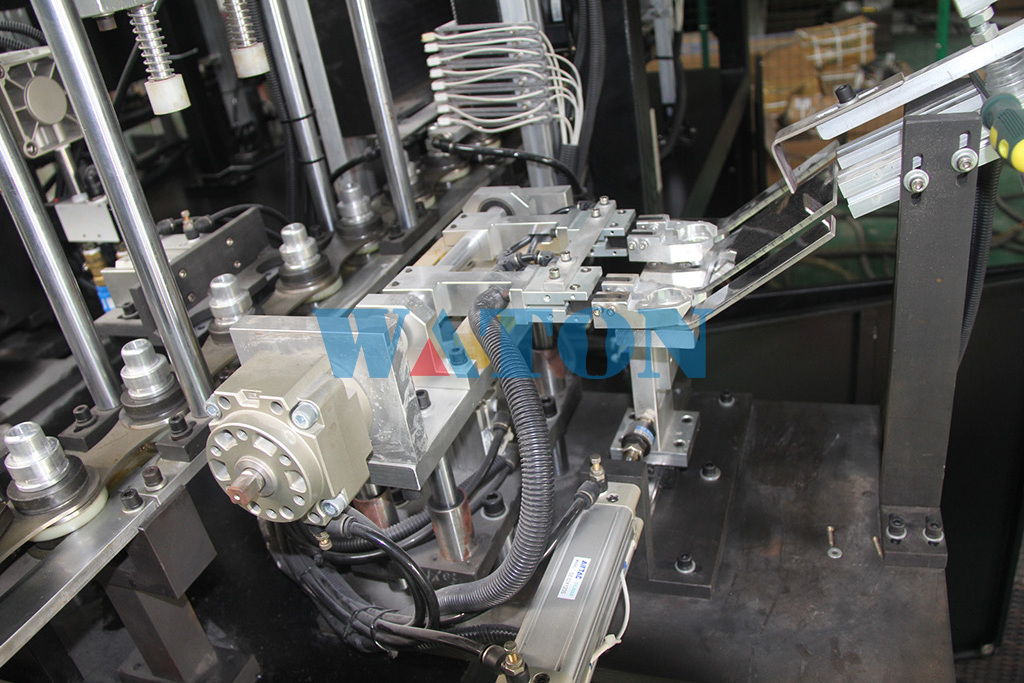

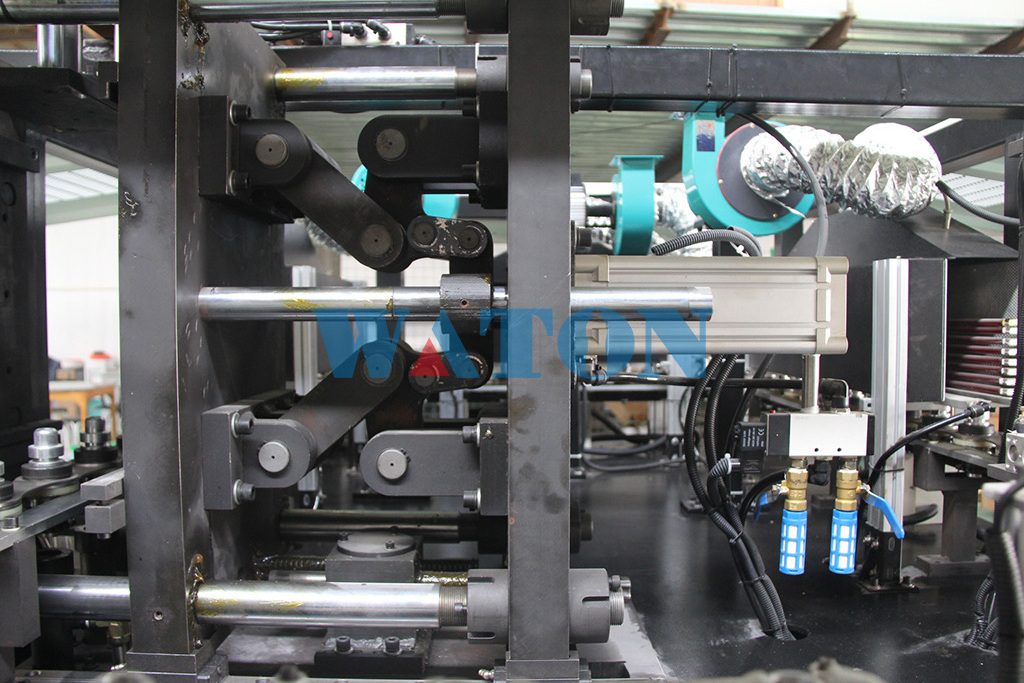

Detailed Images

1.Upgrade to Servo Motor Drive

-Preform Feeding System

-Preform Transfer System

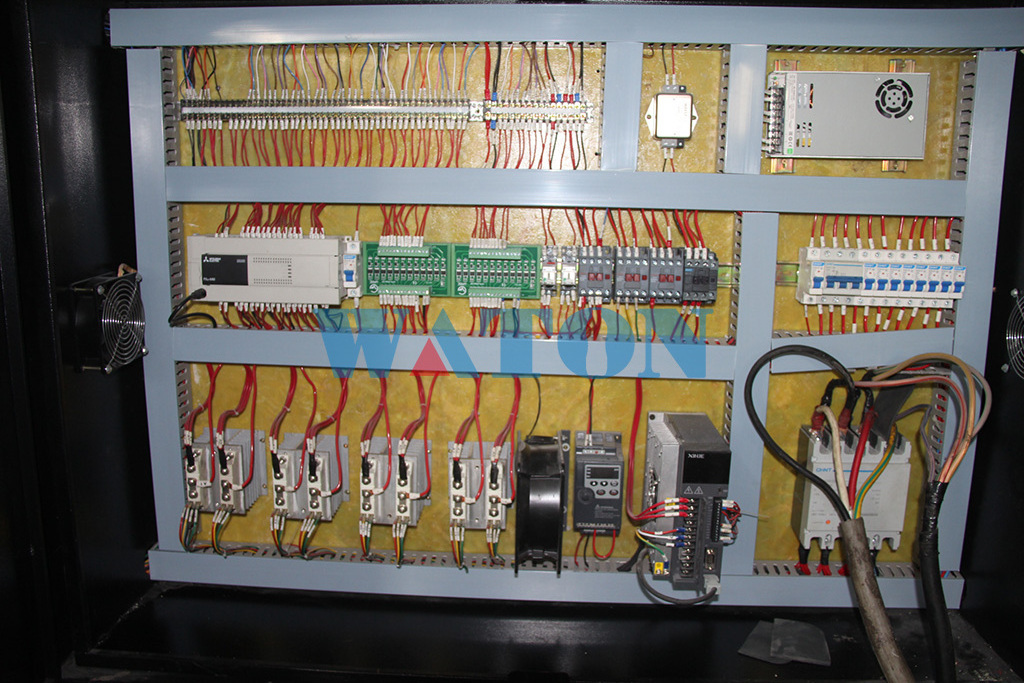

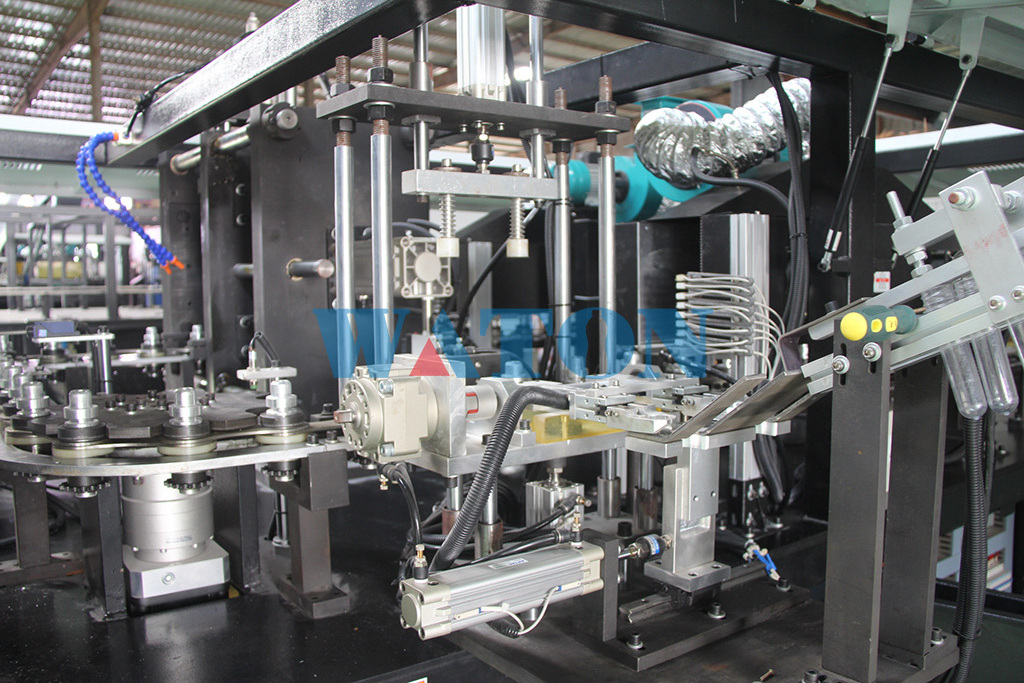

2.Fine Details Customized design

-Mold fixed by Drawer Design. Aluminum mold changeover work can be easily done in half hour.

-Preform Feeding & Transfer Chains adopts composite Nylon polymer, which is light, wear resistant and without deformation.

-The most advanced high frequency Infrared Heaters upgrade the heating efficiency 30%-50%.

-Intelligent temperature control system. It works when large ambient temperature difference(-28~45℃

3.Top quality parts, stable performance

-HMI(Human Machine Interface), overall computer control, easy to operate.

-Independent operation station, more flexible to arrange operating positions. Far away from Heating Area, safe.

-Multi-point photoelectric detection, protect Positioning System, Clamping System and Stretch System.

Specifications

|

Models

|

|

ECO-2

|

ECO-4S

|

ECO-4L

|

ECO-6S

|

ECO-6L

|

|

|

Theoretical Capacity(BPH)

|

|

1,800~2,400

|

4,600~5,000

|

3,600~5,000

|

6,000~7,000

|

5,000~6,000

|

|

|

Mold Cavities

|

|

2

|

4

|

4

|

6

|

6

|

|

|

Bottle

|

Neck Size

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

|

|

|

Max. Volume

|

2000ml

|

750ml

|

2000ml

|

750ml

|

2000ml

|

|

|

|

Max. Diameter

|

105mm

|

69mm

|

105mm

|

69mm

|

105mm

|

|

|

|

Max. Height

|

330mm

|

240mm

|

330mm

|

240mm

|

330mm

|

|

|

Power

|

Heater qty

|

16pcs

|

21pcs

|

32pcs

|

28pcs

|

48pcs

|

|

|

|

Heating Area

|

2

|

3

|

4

|

4

|

6

|

|

|

|

Heating Power

|

35KW

|

46KW

|

70KW

|

62KW

|

106KW

|

|

|

|

Rated General Power

|

37KW

|

50KW

|

75KW

|

65KW

|

110KW

|

|

|

High Pressure Air Consumption(m3/min)

|

|

2.0

|

3.0

|

4.0

|

5.0

|

6.0

|

|

|

Main Machine Size

|

|

3000*1800*2400mm

|

3300*2000*2200mm

|

4200*2100*2400mm

|

4200*2050*2200mm

|

5800*2150*2400mm

|

|

|

Main Machine Weight

|

|

2500KGS

|

3600KGS

|

5000KGS

|

5500KGS

|

7800KGS

|

|

Certifications

Packing&Shipping

B

ecause of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

After Sales Service

after-sales service we offer

1.Your inquiry related to our product & price will be replied within 72 hours.

2.Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3.Working time: 8:30am ~5:30pm, Monday to Saturday.

4.Your business relationship with us will be confidential to any third party.

5.Good after-sales service offered, please get back to us if you got any questions.

Company Introduction

WATON Machinery is a professional manufacturer of two-step linear full-electric high-speed automatic PET bottle blow molding machine, located in Taizhou City, Zhejiang Province. Our team has 20-years experience in PET stretch Blow Molding Machine manufacturing. Since establishment, we have been committed to be a trustworthy and reliable partner, providing customers with high efficiency, low energy consumption, stable operation of equipment and excellent services. Our offer service in:

√Automatic/Semi-auto Electric PET Blow Molding Machine

√Turnkey solution for PET bottle production line

√In-line service for PET bottle production line & Filling line.

Our Services & Strength

Firstly, we manufacture and supply Blow Molding Machine with good quality and reasonable price.

Secondly, we offer turnkey solution. We offer complete line equipment including accessories machines.

Thirdly, we offer bottle design service for free. Leave message or an email to us, we will do our best.

FAQ

Q1: Are you a manufacturer or trading company?

A: We are the manufacturer from Taizhou, so we can offer you the best quality and best price of the machine.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with high quality after-service. Also we have two year warranty of the spare parts, free of charge.

Q3: What is the advantage of servo control?

A3: 1. Precision

2. Fast reaction, make high speed possible

3. Low power consumption

4. Low noise

5. hygiene, without oil leakage problem

Q4: Do you have technical support after we purchased your machines?

A4: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q5: What after-sales service your company offers?

1.Your inquiry related to our product & price will be replied within 72 hours.

2.Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3.Working time: 8:30am ~5:30pm, Monday to Saturday.

4.Your business relationship with us will be confidential to any third party.

5.Good after-sales service offered, please get back to us if you got any questions.

Q6: Can I visit your factory and send team for learning and inspect?

A6:Yes,sure.We will do our best to teaching you how to use the machine.welcome to visit our factory!

Q7: What your advantages are?

A7: 1. Stable running machines with newly technology, competitive price;

2. top rank technical support

3. Best and prompt service

Q8: Where is your factory located? How can we visit there?

A8: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q9: What is your terms of packing?

A9: Because of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

Q10: When Can I get my machine after I paid?

A10: The delivery time is about 30-45 working days

Product Description

|

Models

|

ECO-2L

|

|

Theoretical Capacity

|

1800-2400BPH

|

|

Mold Cavities

|

2

|

|

Neck Size

|

18-38mm

|

|

Max. Volume

|

2000ml

|

|

Advantages

|

High productivity; easy to operate; long time after-sale service.

|

Model ECO-2L Automatic Stretch-blow Machine is newly designed and reformed on previous experience of our manufacture. Main feature of this model:

1.Servo motor controls the preform stepping motion;

2.Compact with 2 cavities, center distance 139.7mm;

3.Newly high efficiency Ruby Heaters;

4.It is an ideal equipment to make different-shaped containers, such as mineral water bottle, beverage bottle, cosmetics bottle, medicine bottle, pesticide bottle, edible-oil bottle, wine bottle, milk bottle, etc.

With reasonable investment and high efficiency, it helps you raise production and

save energy.

Direction for use

1.We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

2.We will send the instruction book to you to let you install the machine. You can talk with our engineer by video chat or we will send the engineers overseas to help you.

WATON Machinery designs the most suitable machine models according to the special requirements of customers, suitable for PET containers from 200ml~20L, including package for water, Carbonated Soft Drink, juice, milk, edible oil, beer, solid food, cosmetics, pharmaceuticals, etc.

Detailed Images

1.Upgrade to Servo Motor Drive

-Preform Feeding System

-Preform Transfer System

2.Fine Details Customized design

-Mold fixed by Drawer Design. Aluminum mold changeover work can be easily done in half hour.

-Preform Feeding & Transfer Chains adopts composite Nylon polymer, which is light, wear resistant and without deformation.

-The most advanced high frequency Infrared Heaters upgrade the heating efficiency 30%-50%.

-Intelligent temperature control system. It works when large ambient temperature difference(-28~45℃

3.Top quality parts, stable performance

-HMI(Human Machine Interface), overall computer control, easy to operate.

-Independent operation station, more flexible to arrange operating positions. Far away from Heating Area, safe.

-Multi-point photoelectric detection, protect Positioning System, Clamping System and Stretch System.

Specifications

|

Models

|

|

ECO-2

|

ECO-4S

|

ECO-4L

|

ECO-6S

|

ECO-6L

|

|

|

Theoretical Capacity(BPH)

|

|

1,800~2,400

|

4,600~5,000

|

3,600~5,000

|

6,000~7,000

|

5,000~6,000

|

|

|

Mold Cavities

|

|

2

|

4

|

4

|

6

|

6

|

|

|

Bottle

|

Neck Size

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

|

|

|

Max. Volume

|

2000ml

|

750ml

|

2000ml

|

750ml

|

2000ml

|

|

|

|

Max. Diameter

|

105mm

|

69mm

|

105mm

|

69mm

|

105mm

|

|

|

|

Max. Height

|

330mm

|

240mm

|

330mm

|

240mm

|

330mm

|

|

|

Power

|

Heater qty

|

16pcs

|

21pcs

|

32pcs

|

28pcs

|

48pcs

|

|

|

|

Heating Area

|

2

|

3

|

4

|

4

|

6

|

|

|

|

Heating Power

|

35KW

|

46KW

|

70KW

|

62KW

|

106KW

|

|

|

|

Rated General Power

|

37KW

|

50KW

|

75KW

|

65KW

|

110KW

|

|

|

High Pressure Air Consumption(m3/min)

|

|

2.0

|

3.0

|

4.0

|

5.0

|

6.0

|

|

|

Main Machine Size

|

|

3000*1800*2400mm

|

3300*2000*2200mm

|

4200*2100*2400mm

|

4200*2050*2200mm

|

5800*2150*2400mm

|

|

|

Main Machine Weight

|

|

2500KGS

|

3600KGS

|

5000KGS

|

5500KGS

|

7800KGS

|

|

Certifications

Packing&Shipping

B

ecause of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

After Sales Service

after-sales service we offer

1.Your inquiry related to our product & price will be replied within 72 hours.

2.Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3.Working time: 8:30am ~5:30pm, Monday to Saturday.

4.Your business relationship with us will be confidential to any third party.

5.Good after-sales service offered, please get back to us if you got any questions.

Company Introduction

WATON Machinery is a professional manufacturer of two-step linear full-electric high-speed automatic PET bottle blow molding machine, located in Taizhou City, Zhejiang Province. Our team has 20-years experience in PET stretch Blow Molding Machine manufacturing. Since establishment, we have been committed to be a trustworthy and reliable partner, providing customers with high efficiency, low energy consumption, stable operation of equipment and excellent services. Our offer service in:

√Automatic/Semi-auto Electric PET Blow Molding Machine

√Turnkey solution for PET bottle production line

√In-line service for PET bottle production line & Filling line.

Our Services & Strength

Firstly, we manufacture and supply Blow Molding Machine with good quality and reasonable price.

Secondly, we offer turnkey solution. We offer complete line equipment including accessories machines.

Thirdly, we offer bottle design service for free. Leave message or an email to us, we will do our best.

FAQ

Q1: Are you a manufacturer or trading company?

A: We are the manufacturer from Taizhou, so we can offer you the best quality and best price of the machine.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you high quality machines with high quality after-service. Also we have two year warranty of the spare parts, free of charge.

Q3: What is the advantage of servo control?

A3: 1. Precision

2. Fast reaction, make high speed possible

3. Low power consumption

4. Low noise

5. hygiene, without oil leakage problem

Q4: Do you have technical support after we purchased your machines?

A4: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q5: What after-sales service your company offers?

1.Your inquiry related to our product & price will be replied within 72 hours.

2.Well-trained & experienced staff will answer all your inquiries in English and Chinese.

3.Working time: 8:30am ~5:30pm, Monday to Saturday.

4.Your business relationship with us will be confidential to any third party.

5.Good after-sales service offered, please get back to us if you got any questions.

Q6: Can I visit your factory and send team for learning and inspect?

A6:Yes,sure.We will do our best to teaching you how to use the machine.welcome to visit our factory!

Q7: What your advantages are?

A7: 1. Stable running machines with newly technology, competitive price;

2. top rank technical support

3. Best and prompt service

Q8: Where is your factory located? How can we visit there?

A8: Our factory is located in Tai Zhou City, Zhe Jiang Province, China. From Shanghai to our city, it takes 3.5hrs by train, 45mins by air.

Q9: What is your terms of packing?

A9: Because of the new provisions on fumigation, we pack machines with bubble film and wrap film. It is safe pack in container. We can also do wooden case. Some countries require fumigation for wooden case. It depends on your country’s requirement.

Q10: When Can I get my machine after I paid?

A10: The delivery time is about 30-45 working days

Hot Searches