- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

bekebe

-

Product Name:

-

concrete angel mold

-

Application:

-

exterior decoration

-

Material:

-

fiberglass silicone rubber

-

Mould Life:

-

5years

-

Certification:

-

ISO

-

Delivery Time:

-

7Days

-

MOQ:

-

1piece

-

Service:

-

good

-

Advantage:

-

durable

-

Quality:

-

nice

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

bekebe

-

Model Number:

-

bekebe

-

Product Name:

-

concrete angel mold

-

Application:

-

exterior decoration

-

Material:

-

fiberglass silicone rubber

-

Mould Life:

-

5years

-

Certification:

-

ISO

-

Delivery Time:

-

7Days

-

MOQ:

-

1piece

-

Service:

-

good

-

Advantage:

-

durable

-

Quality:

-

nice

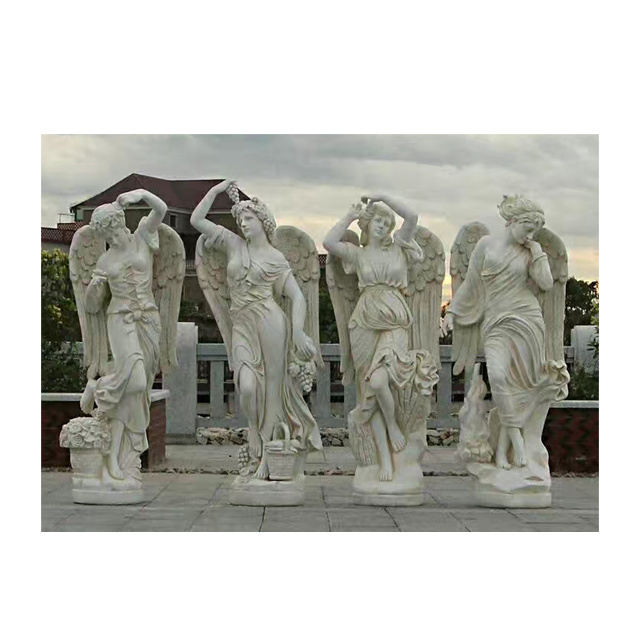

Products Description

For Customization series, we supply

Figure sculpture mould, Buddha statue mould, flower pot mould, tea tray mould, handicraft mould, furniture mould, wash basin mould, resin staircase handrail mould, coffee table mould and so on.

The molds are silicone materials, or fiberglass outer molds, silicone rubber materials inner mold.

Whats more, we support to customized, all kinds of designs and types, only need you to supply pictures sizes or drawings.

|

Name

|

Statue molds

|

|

|

|

|||

|

Materials

|

Silicone rubber, fiberglass

|

|

|

|

|||

|

Designs

|

European, retro, modern

|

|

|

|

|||

|

Molds life

|

3-5years

|

|

|

|

|||

|

Customize

|

Support, supply drawings or pictures

|

|

|

|

|||

|

Quality

|

Nice, durable.

|

|

|

|

|||

Flower pot manufacture process

Step 1: install the molds

Step 2: place the rebars and spray oil

Step 3: casting concrete

Step 4: release the molds after dry

Step 5: finished products

Step 6: Spray painting.

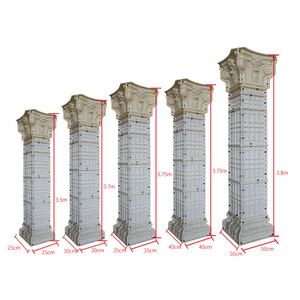

Roman pillar manufacture process

Step1: Install the molds

Step 2: Place into the rebars

Step 3: Casting concrete

Step 4: Release the molds after dry

Step 5: Finished products

Step 6: Effect pictures

Recommend Products

concrete window molds

concrete cornice molds

flower plate molds

baluster decorations molds

casting in site baluster molds

fence molds

chair molds

bench molds

trash can molds

pavilion molds

fountain molds

stair molds

coffe table molds

fiberglass cornice molds

lamp panel molds

wall panel molds

3D background wall molds

ceiling molds

aluminium cornice molds

gypsum cornice production line

PU crown molds

PU cornice molds

PU corner molds

PU ceiling molds

brick making machine

concrete mixer

concrete stamp molds

DIY pathway molds

hollow brick molds

Iron oxide pigment

Hot Searches