- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

27400*2200*2350mm(L*W*H)

-

Weight:

-

9000 KG

-

Power:

-

35KW

-

Spindle gauge:

-

150mm

-

Roller frame:

-

90°

-

Ring diameter:

-

115mm/90mm

-

Hollow spindle rotate speed:

-

3000~9000RPM

-

Direction of twist:

-

S&Z

-

Lifting distance:

-

220~330mm

-

Twist before untwisting:

-

200~2000T/m

-

Draft ratio:

-

1~50

-

Super feeding ratio:

-

1:1~8:1

-

Output line speed:

-

2~22m/min

Quick Details

-

Applicable Industries:

-

Fancy yarn industry

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

27400*2200*2350mm(L*W*H)

-

Weight:

-

9000 KG

-

Power:

-

35KW

-

Spindle gauge:

-

150mm

-

Roller frame:

-

90°

-

Ring diameter:

-

115mm/90mm

-

Hollow spindle rotate speed:

-

3000~9000RPM

-

Direction of twist:

-

S&Z

-

Lifting distance:

-

220~330mm

-

Twist before untwisting:

-

200~2000T/m

-

Draft ratio:

-

1~50

-

Super feeding ratio:

-

1:1~8:1

-

Output line speed:

-

2~22m/min

Product Description

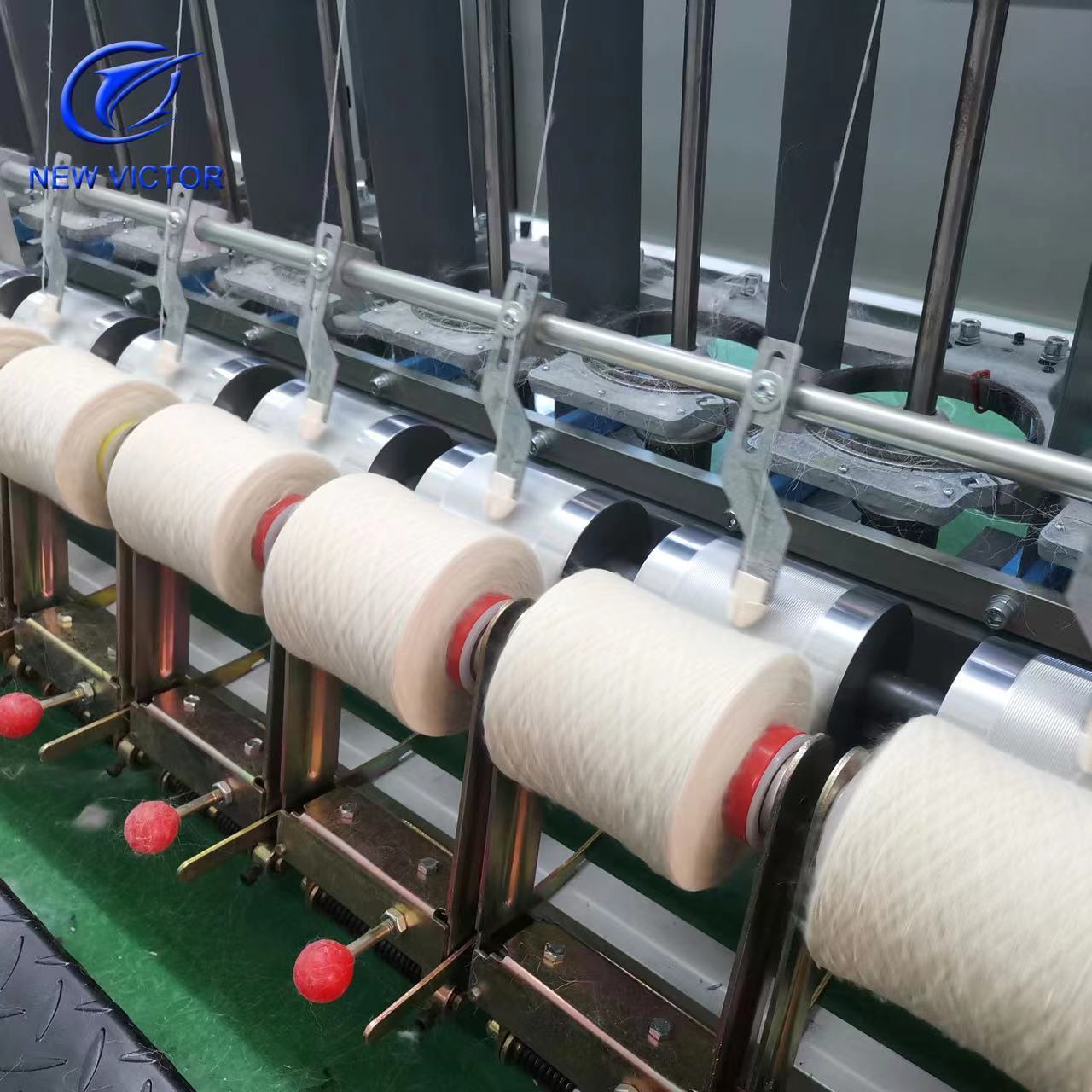

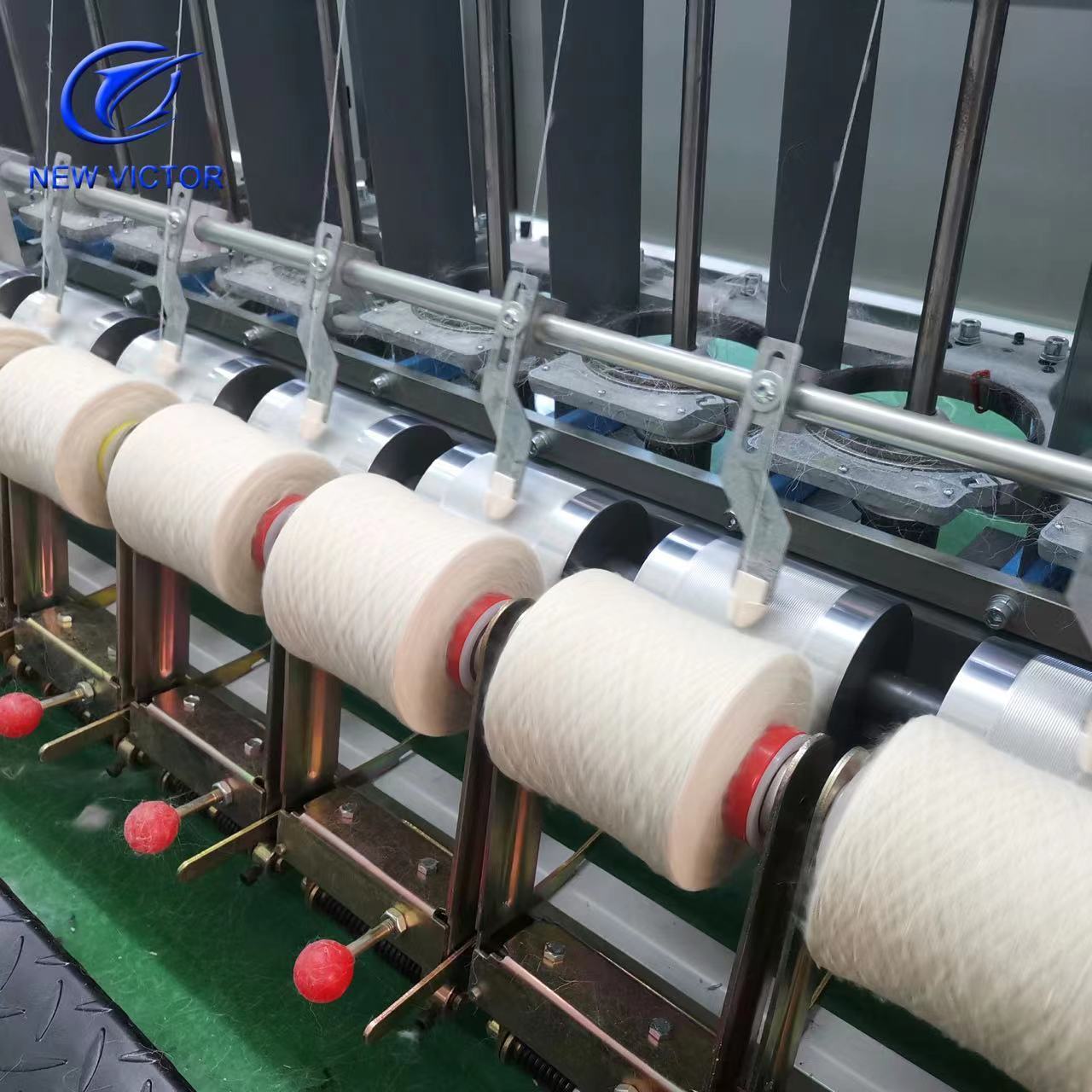

Fancy Yarn Twisting Machine

Fancy yarn twisting machine is a new type ultrafine fancy yarn twister developed by extensively absorbing our customer experience and foreign technology, This Unit is mainly suitable for spinning medium-high count fancy yarn with high quality and stable pattern.

Features

• The speed and untwisting twist of each roller can be step-less adjusted to ensure the process adjustments convenient and quick.

• The ring spindles and hollow spindles are all controlled by independent inverters, transmitted by a long belt, which decreases the spindle difference and improves the products quality.

• Adopting the servo motor to keep operation smooth with lower noise and finished yarn with lower breaking rate.

• The portal frame exerts force on the two ends and is put pressure on the middle, which ensures on rollers is balanced. And the forcing roller is 3-level adjustable. Through these, even if the raw material and yarn fibers are totally different in the length and thickness, it makes the adjustment flexible, improves the yarn quality, decreases the spindle difference and reduces the raw material waste.

• Adopting slotted roller ensures stable and reliable in the yarn forming process.

Specification

|

item

|

value

|

|

Applicable Industries

|

Fancy yarn industry

|

|

Showroom Location

|

Egypt, India

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2023

|

|

Warranty of core components

|

3 years

|

|

Core Components

|

PLC

|

|

Condition

|

New

|

|

Type

|

Twisting Machine

|

|

Place of Origin

|

China

|

|

Dimension(L*W*H)

|

27400*2200*2350mm(L*W*H)

|

|

Power

|

35KW

|

|

Warranty

|

3 years

|

|

Spindle gauge

|

150mm

|

|

Roller frame

|

90°

|

|

Ring diameter

|

115mm/90mm

|

|

Hollow spindle rotate speed

|

3000~9000RPM

|

|

Direction of twist

|

S&Z

|

|

Lifting distance

|

220~330mm

|

|

Twist before untwisting

|

200~2000T/m

|

|

Draft ratio

|

1~50

|

|

Super feeding ratio

|

1:1~8:1

|

|

Front-rear roller diameter

|

45mm

|

|

Middle roller diameter

|

26mm

|

|

Core roller diameter

|

40mm

|

|

Output roller diameter

|

45mm

|

|

Output line speed

|

2~22m/min

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches