- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.2~0.4%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

1.2-1.4%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

clay fire brick

-

Brand Name:

-

KRNC

-

Product name:

-

fire clay bricks

-

Application:

-

Metallurgy

-

Name:

-

Clay Brick

-

Color:

-

grey

-

Raw material:

-

High Alumina Bauxite

-

Size:

-

230*114*65mm

-

BULK DENSITY:

-

0.5-1.3

-

Type:

-

Ceramic Raw Materials

-

Certificate:

-

ISO9001

-

Usage:

-

Furnace Liner

Quick Details

-

SiO2 Content (%):

-

1.0%

-

Al2O3 Content (%):

-

30%-45%

-

MgO Content (%):

-

0.05%Max

-

CaO Content (%):

-

0.2~0.4%

-

CrO Content (%):

-

0

-

SiC Content (%):

-

1.2-1.4%

-

Place of Origin:

-

Henan, China

-

Model Number:

-

clay fire brick

-

Brand Name:

-

KRNC

-

Product name:

-

fire clay bricks

-

Application:

-

Metallurgy

-

Name:

-

Clay Brick

-

Color:

-

grey

-

Raw material:

-

High Alumina Bauxite

-

Size:

-

230*114*65mm

-

BULK DENSITY:

-

0.5-1.3

-

Type:

-

Ceramic Raw Materials

-

Certificate:

-

ISO9001

-

Usage:

-

Furnace Liner

Chinese manufacturer fire clay anchor brick for chimney supplier

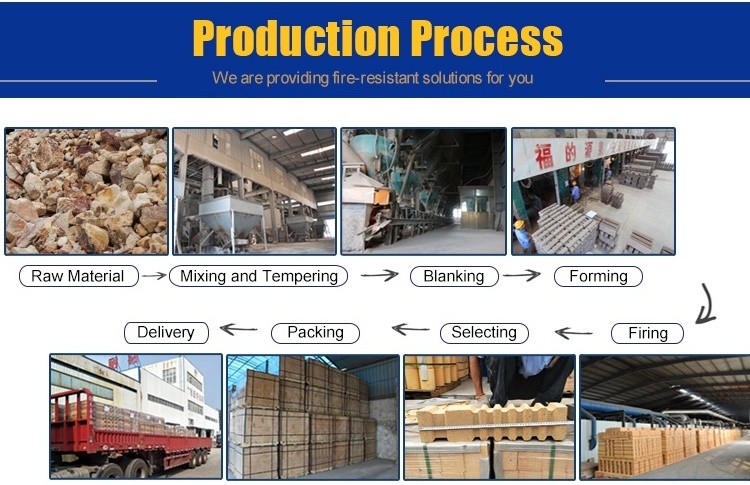

Kerui Refractory adopts supreme 50% soft and 50% hard chamotte, then put in moderate auxiliary material and some additive based on normal clay to produce fire clay brick. After fine grinding, mixing and high pressure molding, it turns into mullite phase, which has good mineral composition, to ensure the product be with high refractoriness, compact density, low apparent porosity, good low creep at high temperature and bulk stability.

Performance Characters:

Fire clay brick is a kind of weak acid refractory product. It can resist the corrosion of acid slag and acid gas, but of low resistance to alkaline matters. It is of good thermal performance and good thermal shock resistance.

Main Application:

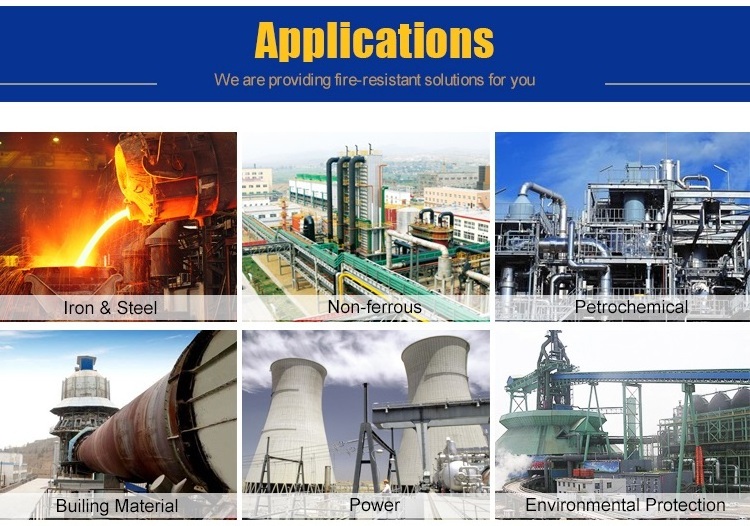

It is mainly used for carbon furnace, baking furnace, heating boiler, glass furnace, cement kiln, fertilizer gasification furnace, blast furnace, the hot blast stove, coking furnace, furnace, casting and casting steel brick, etc.

Standard size: 230x114x65mm, special size and OEM service are provided, too.

|

Item/Grade |

Fire Clay Brick |

High Alumina Brick |

||||||

|

SK-30 |

SK-32 |

SK-34 |

SK-35 |

SK-36 |

SK-37 |

SK-38 |

SK-40 |

|

|

AL2O3% (≥) |

30 |

35 |

38 |

45 |

55 |

65 |

70 |

82 |

|

Fe2O3% (≤) |

2.5 |

2.5 |

2 |

2 |

2 |

2 |

2 |

2 |

|

Refractoriness(SK) |

30 |

32 |

34 |

35 |

36 |

37 |

38 |

40 |

|

Refractoriness under load, 0.2MPa, °C (≥) |

1250 |

1300 |

1360 |

1420 |

1450 |

1480 |

1530 |

1600 |

|

Apparent porosity (%) |

22-26 |

20-24 |

20-22 |

18-20 |

20-23 |

20-23 |

20-22 |

18-20 |

|

Bulk density (g/cm³) |

1.9-2.0 |

1.95-2.1 |

2.1-2.2 |

2.15-2.22 |

2.25-2.4 |

2.3-2.5 |

2.4-2.6 |

2.5-2.7 |

|

Cold crushing strength ,MPa (≥) |

20 |

25 |

30 |

40 |

45 |

50 |

60 |

70 |

Bisected Fire Clay Brick: 230x115x20mm

Trisected Fire Clay Brick: 230x115x30mm

Quartered Fire Clay Brick: 230x115x40mm

Currently, our products have been used in many carbon burning furnaces, CFB boilers in power plant, cement rotary kilns, non-ferrous metal melting furnaces, blast furnaces, hot-blast furnaces, coking furnaces, steel ladles, glass melting kilns and other high temperature industries all over the world.