1. Heat exchangers and condensers

2. Seawater desalination industry

3. Chemical Industry,

4. Electroplating equipment

5. Precision instruments

6. Environmental protection equipment

7. Auto industry

8. Medical and Sports industry

9. Electric power industry

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Width:

-

<3000mm

-

Ti (Min):

-

99.6%

-

Model Number:

-

Grade 5 titanium sheets

-

Product name::

-

titanium sheet

-

Finishing:

-

pickling, machining, abrasive blasting

-

density:

-

about 4.51g/cm3

-

Ti (Min)::

-

99.6%

-

Standard:

-

ASTMB265, AMS4911, GB/T 3621, etc.

-

melting point:

-

1678

-

MOQ:

-

1kg

-

Condition::

-

Vacuum Annealing

Quick Details

-

Application:

-

Industry,plane, Medical plant

-

Length:

-

<6000mm, <6000mm

-

Technique:

-

Cold Rolled

-

Place of Origin:

-

Shanghai, China

-

Width:

-

<3000mm

-

Ti (Min):

-

99.6%

-

Model Number:

-

Grade 5 titanium sheets

-

Product name::

-

titanium sheet

-

Finishing:

-

pickling, machining, abrasive blasting

-

density:

-

about 4.51g/cm3

-

Ti (Min)::

-

99.6%

-

Standard:

-

ASTMB265, AMS4911, GB/T 3621, etc.

-

melting point:

-

1678

-

MOQ:

-

1kg

-

Condition::

-

Vacuum Annealing

Product Show

Hot selling 1mm 2mm 3mm 4mm 5mm ti plate Grade 1 grade 2 grade 5 titanium sheet plate

Product Description

Application:(Titanium plate/sheet)

|

Product name

|

Hot sale ASTM B265 3.0mm Grade 5 titanium sheet plate

|

|

Material grade

|

Gr1, Gr2, Gr4, Gr5,Gr7, Gr9, Gr23, TI-6Al4v,

|

|

Certificate

|

ISO9001:2008,TUV, material test certificate EN10204.3.1

|

|

Standard

|

ASTM B265,ASME SB265,AMS4911,ASTM F136,ASTM F67

|

|

Tehnique

|

Hot/cold rolled

|

|

Surface

|

Acid wash,polished

|

|

Dimensions

|

Thickness:0.3-100mm

|

|

|

Width:20-1220mm

|

|

|

Length:500-6000mm

|

Features of titanium plate

*

Low density (relatively light-weight).

* Exceptional erosion and erosion-corrosion resistance.

* High fatigue strength in the air and chloride environments.

* High fracture toughness in air and chloride environments.

* Low modulus of elasticity.

* Low thermal expansion coefficient.

* Excellent cryogenic properties.

* High intrinsic shock resistance.

* High ballistic resistance-to-density ratio.

* Exceptional erosion and erosion-corrosion resistance.

* High fatigue strength in the air and chloride environments.

* High fracture toughness in air and chloride environments.

* Low modulus of elasticity.

* Low thermal expansion coefficient.

* Excellent cryogenic properties.

* High intrinsic shock resistance.

* High ballistic resistance-to-density ratio.

Size of

titanium plate /sheet/coil/strip

Thickness(0.5mm-0.7mm)*Width≤1000mm*L≤2000mm

Thickness(0.8mm-4.0mm)*Width≤2000mm*L≤6000mm

Thickness(5.0mm-50mm)*Width≤2000mm*L≤6000mm

Thickness(60mm-100mm)*Width≤2000mm*L≤6000mm

Thickness(0.5mm-0.7mm)*Width≤1000mm*L≤2000mm

Thickness(0.8mm-4.0mm)*Width≤2000mm*L≤6000mm

Thickness(5.0mm-50mm)*Width≤2000mm*L≤6000mm

Thickness(60mm-100mm)*Width≤2000mm*L≤6000mm

Chemcial Composition

|

Grade

|

Chemical Composition (<%)

|

|

|

|

|

|

|

|

|

||||||||

|

|

Ti

|

Al

|

V

|

Fe

|

C

|

N

|

H

|

O

|

Other Max

|

||||||||

|

Gr1

|

Blance

|

---

|

---

|

0.2

|

0.08

|

0.03

|

0.01

|

0.18

|

0.4

|

||||||||

|

Gr2

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Gr3

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.05

|

0.01

|

0.35

|

0.4

|

||||||||

|

Gr4

|

Blance

|

---

|

---

|

0.5

|

0.08

|

0.05

|

0.01

|

0.4

|

0.4

|

||||||||

|

Gr5

|

Blance

|

5.5-6.75

|

3.5-4.5

|

0.4

|

0.08

|

0.05

|

0.01

|

0.2

|

0.4

|

||||||||

|

Gr7

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Gr9

|

Blance

|

2.5-3.5

|

2.0-3.0

|

0.25

|

0.08

|

0.03

|

0.01

|

0.15

|

0.4

|

||||||||

|

Gr12

|

Blance

|

---

|

---

|

0.3

|

0.08

|

0.03

|

0.01

|

0.25

|

0.4

|

||||||||

|

Grade

|

Tensil strength (min)

|

|

Yeild strength (min)

|

|

Elongation (%)

|

||

|

|

KSi

|

MPa

|

KSi

|

MPa

|

|

||

|

Gr1

|

35

|

240

|

20

|

138

|

24

|

||

|

Gr2

|

50

|

345

|

40

|

275

|

20

|

||

|

Gr3

|

65

|

450

|

55

|

380

|

18

|

||

|

Gr4

|

80

|

550

|

70

|

483

|

15

|

||

|

Gr5

|

130

|

895

|

120

|

828

|

10

|

||

|

Gr7

|

50

|

345

|

40

|

275

|

20

|

||

|

Gr9

|

90

|

620

|

70

|

438

|

15

|

||

|

Gr12

|

70

|

438

|

50

|

345

|

10

|

||

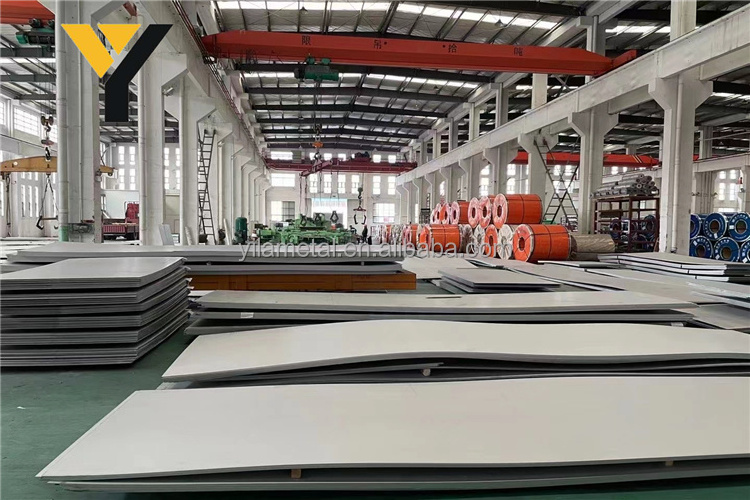

One-Stop Service

Laser cutting

Slitting

Water Jet Cutting

Heat treatment

Polishing

Milling

Technological Process

Packaging & Delivery

1. In spool and plywooden box

2. In coil and woven belt

2. In coil and woven belt

Hot Searches