- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHONGYUAN

-

Dimension(L*W*H):

-

Defined

-

Briquette shape:

-

Pillow or defined

-

Pressure:

-

100t

-

Roller diameter:

-

520mm

-

Roller Width:

-

400mm

-

Capacity:

-

5-8t/h

-

Weight:

-

8.9t

-

Working Theory:

-

Hydraulic Roller Press

-

Installation:

-

Under Engineers Guidance

-

Color:

-

Custom-Made

-

Application:

-

Charcoal Briquetting Coking Formed Coke

Quick Details

-

Weight (KG):

-

8900

-

Core Components:

-

other

-

Production Capacity:

-

5-8t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZHONGYUAN

-

Dimension(L*W*H):

-

Defined

-

Briquette shape:

-

Pillow or defined

-

Pressure:

-

100t

-

Roller diameter:

-

520mm

-

Roller Width:

-

400mm

-

Capacity:

-

5-8t/h

-

Weight:

-

8.9t

-

Working Theory:

-

Hydraulic Roller Press

-

Installation:

-

Under Engineers Guidance

-

Color:

-

Custom-Made

-

Application:

-

Charcoal Briquetting Coking Formed Coke

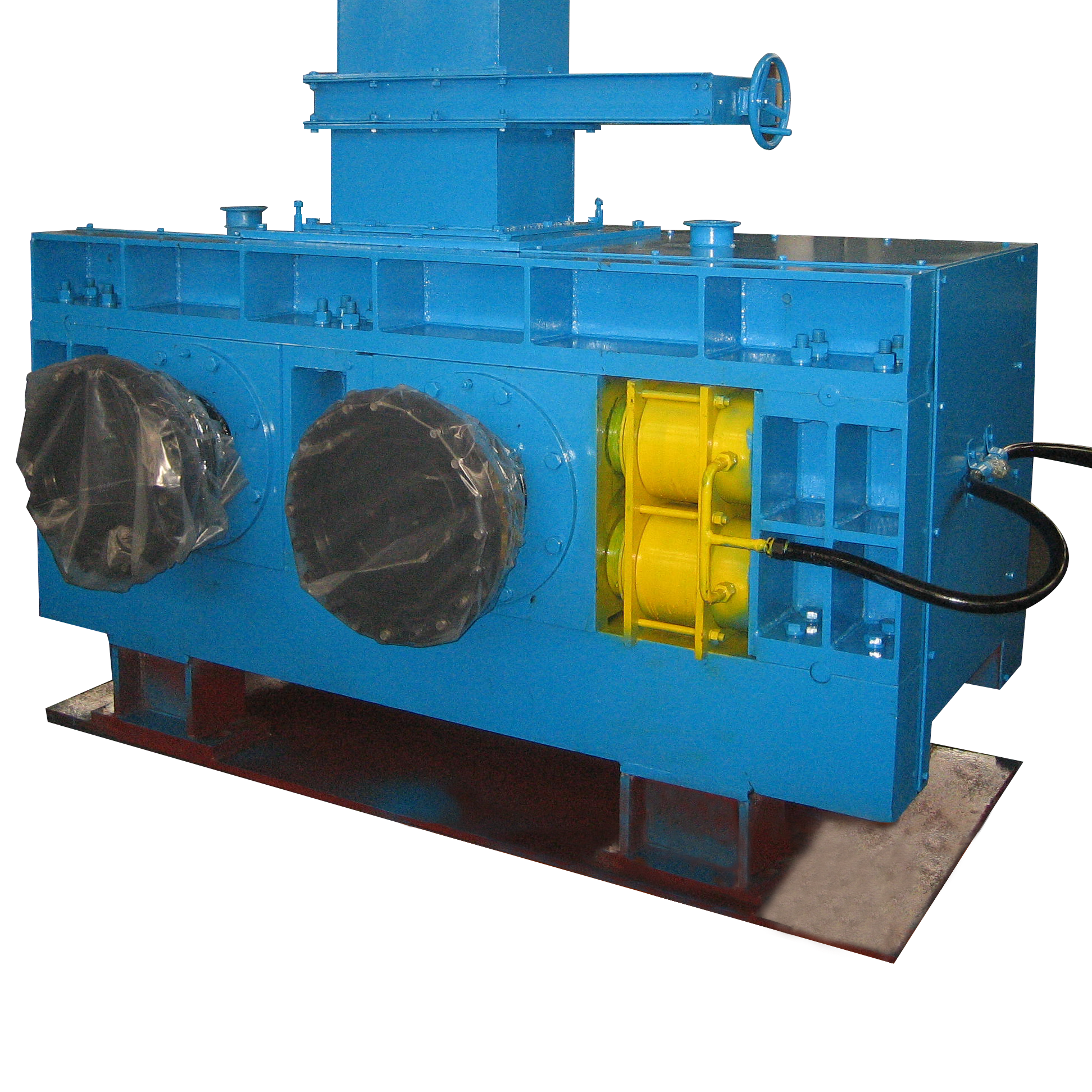

Product introduction

Medium-pressure briquetting machine is newly developed ball pressing equipment which is mainly for materials balling easily and containing more moisture. It is mainly used for briquetting powder materials which its line specific pressure is 1-3t/cm such as coal briquette and formed coke.

Advantages and features

1. Adopting the structure of dual-output shaft reducer, improving the roller precision;

2. Using hard surface gear to improve the working performance and service life of reducer greatly;

3. Using the alignment structure of ball groove of high pressure briquetting machine, more convenient for adjustment;

4. Hydraulic station is placed independently with the function of pressure-adjusting and protective function when overloading.

Order notes:

1. The equipment is supplied as right-installed generally. Please specify in the contract if it needs to be installed at left.

2. The capacity and energy-consumption are related with the following factors such as material characteristics, size of finished products. The capacity in the sheet is calculated based on the density of briquetted ball of coal dust with the standard size of briquetting in our company;

3. The company provides general motor for main frame. Please specify in the contract if variable frequency motor is required.

|

Model |

Roller dia.(mm) |

Roller width (mm) |

Total pressure (t) |

Max. line specific pressure(t/cm) |

Power(kw) |

Capacity(t/h) |

Weight (t) |

|

ZY520-100 |

520 |

400 |

100 |

2.5 |

37 |

5-8 |

8.9 |

|

ZY650-120 |

650 |

500 |

120 |

2.5 |

45 |

10-15 |

12.8 |

|

ZY750-150 |

750 |

480 |

150 |

3 |

75 |

15-20 |

17.2 |

|

ZY1000-300 |

1000 |

900 |

300 |

3 |

200 |

30-35 |

42 |

|

ZY1200-300 |

1200 |

1000 |

300 |

3 |

250 |

45-50 |

78 |

|

ZY1400-360 |

1400 |

1200 |

360 |

3 |

355 |

75-80 |

115 |

Q1 Why choose us ?

We have a professional rich experiences stuffs;

We have the largest factories and production capacity since 1986;

The ZHONGYUAN euqipment, worthy of your trust!

Q2Does the equipment have any special Advantages?

1. The application of high pressure grinding roll can improve the productivity of the powder grinding system by 20%-30%.Power consumption of grinding system can decrease by 25-50% compared with the traditional grinding method.

2.The machine is equipped with sealing cap for rollers which can control the harmful dust spread to create a better production environment.

3.The machine has following advantages such as compact structure, less space-occupation, high reliability. Its operation efficiency can be up to approx.95%.

4.It is lower energy-consumption, less pollution which is the energy conservation and emission reduction and environmental protection product.