- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

162

-

Voltage:

-

220

-

Current:

-

robot arm

-

Rated Capacity:

-

220V

-

Rated Duty Cycle:

-

1000W

-

Dimensions:

-

1000MM*1000MM*1000MM

-

Usage:

-

Applying/Painting/Glueing, Arc Welding

-

Product name:

-

Automatic robotic arm 6 axis

-

Feature:

-

Top performance/Faster start of production/Compact and cost-efficient

-

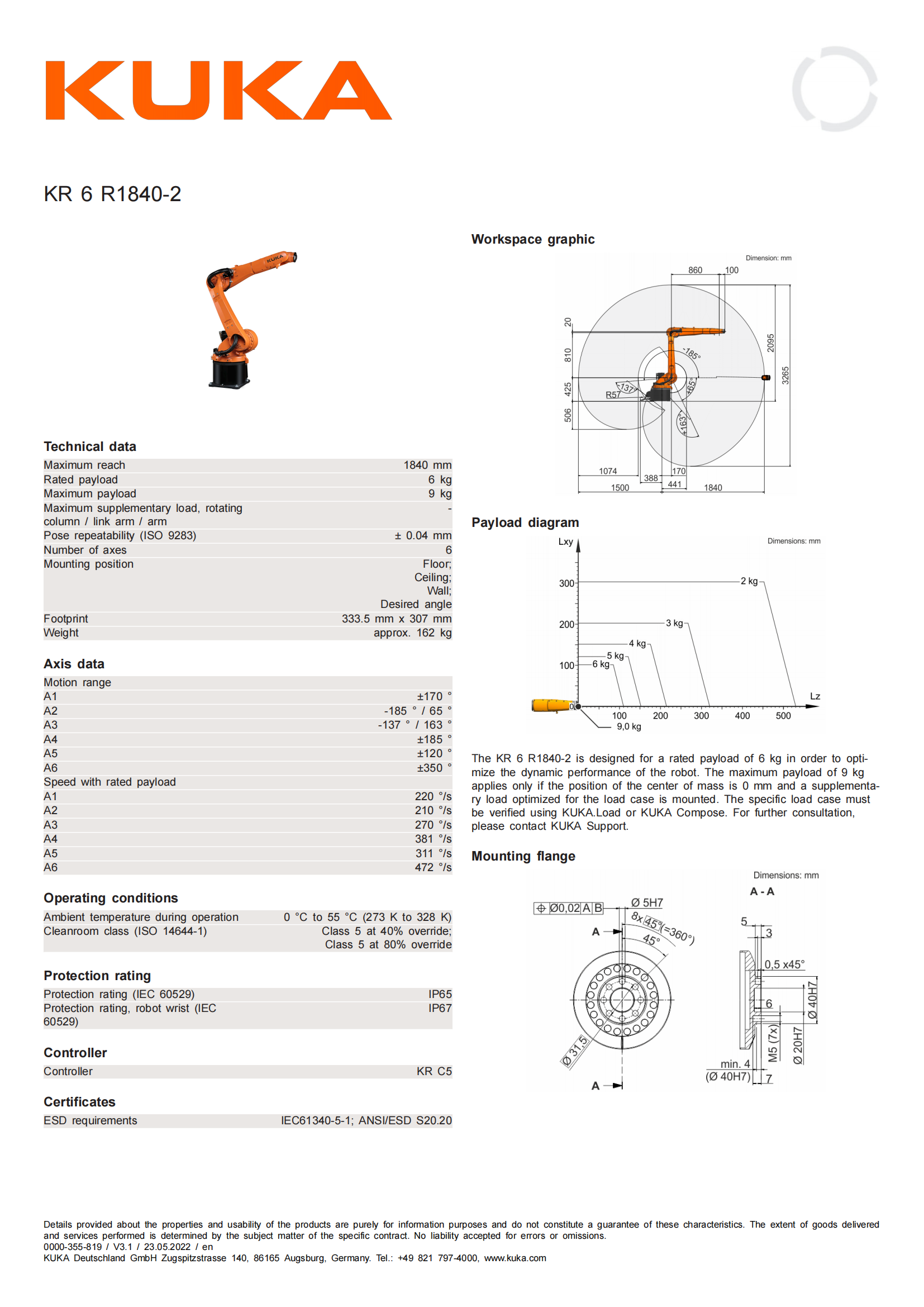

Maximum payload:

-

9 kg

-

9 kg Rated payload:

-

6 kg

-

Maximum reach:

-

1840 mm

-

Mounting position:

-

Floor, Ceiling, Wall, Desired angle

-

Pose repeatability (ISO 9283):

-

0.04 mm

-

Controller:

-

KR C5, KR C5 micro

-

Ambient temperature during operation:

-

0 °C to 55 °C (273 K to 328 K)

-

Ambient temperature during stor./transp.:

-

-40 °C to 60 °C (233 K to 333 K)

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Guangdong

-

Brand Name:

-

KUKA

-

Weight (KG):

-

162

-

Voltage:

-

220

-

Current:

-

robot arm

-

Rated Capacity:

-

220V

-

Rated Duty Cycle:

-

1000W

-

Dimensions:

-

1000MM*1000MM*1000MM

-

Usage:

-

Applying/Painting/Glueing, Arc Welding

-

Product name:

-

Automatic robotic arm 6 axis

-

Feature:

-

Top performance/Faster start of production/Compact and cost-efficient

-

Maximum payload:

-

9 kg

-

9 kg Rated payload:

-

6 kg

-

Maximum reach:

-

1840 mm

-

Mounting position:

-

Floor, Ceiling, Wall, Desired angle

-

Pose repeatability (ISO 9283):

-

0.04 mm

-

Controller:

-

KR C5, KR C5 micro

-

Ambient temperature during operation:

-

0 °C to 55 °C (273 K to 328 K)

-

Ambient temperature during stor./transp.:

-

-40 °C to 60 °C (233 K to 333 K)

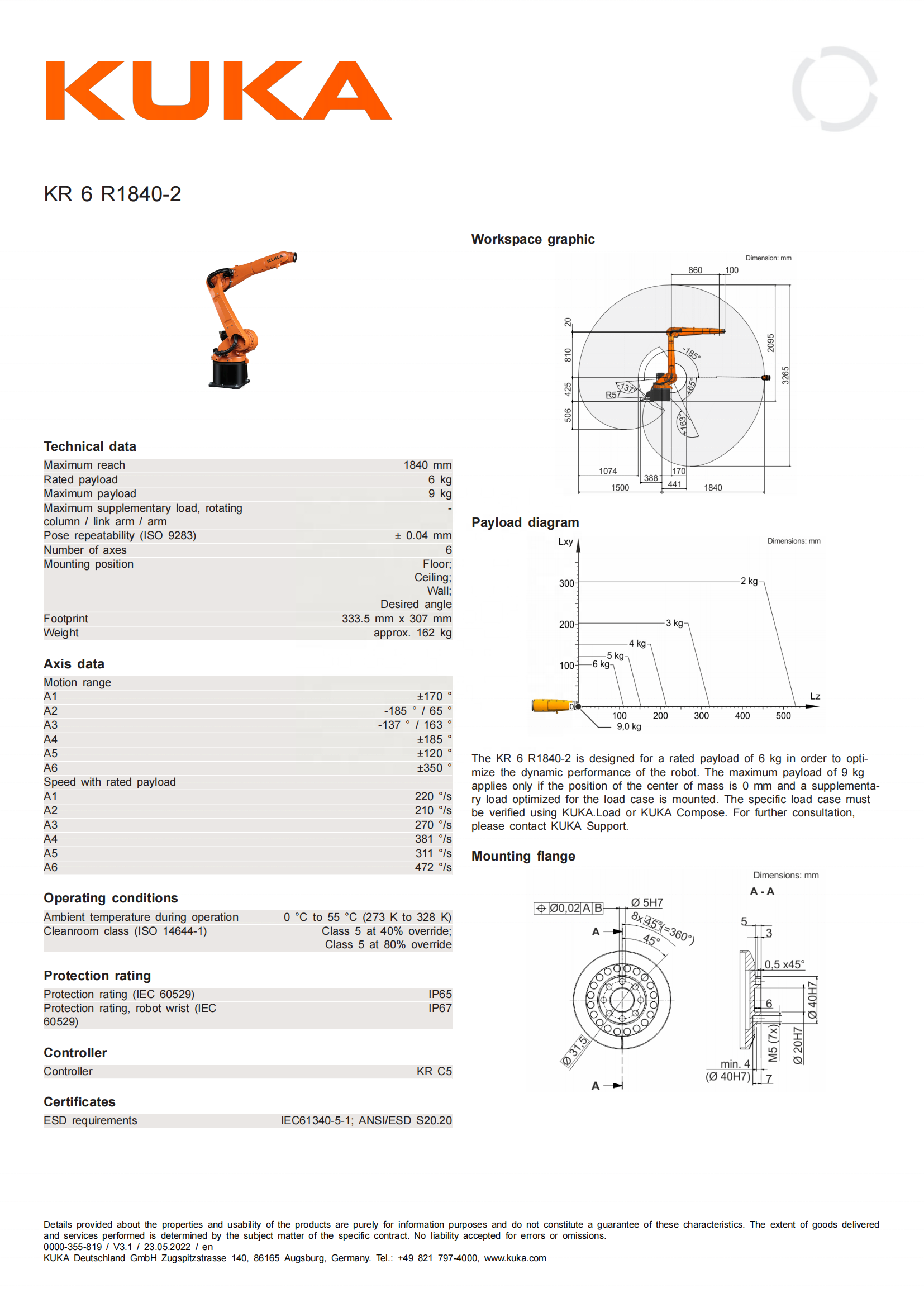

Products Description

KUKA offers a comprehensive range of industrial robots, catering to diverse applications with precision, flexibility andefficiency. Whether you're looking for new robotic solutions or cost-effective options through our selection of used robots, we've got you covered for all your automation needs.

KR CYBERTECH nano

Top performance with a high power density: The specialized process robots of the KR CYBERTECH nano product family are perfectly tailored to handle small components. Benefit from maximum diversity for greater economical flexibility with minimum investment and energy costs.

Flexible, cost-effective robots for applications such as handling, welding, palletizing or adhesive bonding

The industrial robots of the KR CYBERTECH nano family are optimized for handling small components in virtually unlimited applications. The very fine payload intervals of 6, 8 and 10 kilograms and the perfectly coordinated robot types mean that you can select precisely the robot you actually need – for maximum efficiency and cost-effectiveness.

ESD protection

The robot is protected against uncontrolled electrostatic charging or discharging (ESD) and is thus suitable for the handling of sensitive electronic components.

Software add-ons

With digital Motion Modes, you can simply adapt the performance of the robot via the robot controller – e.g. for optimized precision or speed.

Suitable for use in humid or harsh environments

The main axes are protected to IP 65 against dust and water, the wrist axes even to IP 67.

Suitable for compact cells

With a streamlined design, the robots ensure ideal utilization of the space in compact robotic cells.

Advantages

Utmost precision

The industrial robots of the KR CYBERTECH nano family offer a repeatability of 0.04 millimeters. They therefore take fulladvantage of their strengths even at high speed.

Streamlined and compact

Maximum performance with minimal disruptive contours: the new robots are extremely compact, light and streamlined – for a wide range of applications in industrial manufacturing.

Maximum freedom Maximum flexibility

The robots open up previously inaccessible workspaces: they can cover long distances, with an extremely large workspace to the rear and a long downward reach.

Install the KR CYBERTECH nano industrial robots on the floor, wall or ceiling, or at any other angle – for a wide range of different requirement profiles in any desired installation position.

Most streamlined in-line wrist Maximum flexibility

With an interference radius of just 67 millimeters, the KR CYBERTECH nano handling robots have the smallest in-line wrist in their class – worldwide. It enables work to be carried out in positions that are inaccessible for other robots.

Simply integrate external axes via the robot controller and benefit from the innovative K-PIPE-ES energy supply concept.

KR CYBERTECH nano data overview

|

|

KR 6 R1840-2

|

KR 8 R1620

|

KR 8 R1640-2

|

KR 10 R1420

|

KR 10 R1440-2

|

KR 10 R1440-2 HO

|

|

Payload

|

6 kg

|

8 kg

|

8 kg

|

10 kg

|

10 kg

|

10 kg

|

|

Maximum reach

|

1840 mm

|

1620 mm

|

1640 mm

|

1420 mm

|

1440 mm

|

1440 mm

|

|

Construction type

|

Standard

|

Standard

|

Standard

|

Standard

|

Standard

|

Standard

|

|

Version environment

|

Standard

|

Standard

|

Standard

|

Standard

|

Standard

|

Food

|

|

Mounting positions

|

Angle, Ceiling, Floor, Wall

|

Angle, Ceiling, Floor, Wall

|

Angle, Ceiling, Floor, Wall

|

Angle, Ceiling, Floor, Wall

|

Angle, Ceiling, Floor, Wall

|

Angle, Ceiling, Floor, Wall

|

|

Protection class

|

IP 65, IP 67

|

IP 54

|

IP 65, IP 67

|

IP 54

|

IP 65, IP 67

|

IP 65, IP 67

|

Suitable for these applications

* Mechanical machining & polishing * Handling

* Assembly * Arc welding

* Cutting/Separation * Applying / Painting / Glueing

* Palletizing/ Packaging * Measuring / Inspection

* Pick & Place * Machine loading/unloading

* Other

* Mechanical machining & polishing * Handling

* Assembly * Arc welding

* Cutting/Separation * Applying / Painting / Glueing

* Palletizing/ Packaging * Measuring / Inspection

* Pick & Place * Machine loading/unloading

* Other

Specification

Designed for special applications

* Streamlined design: space-saving thanks to an even more compact design and even smaller footprint than the KR CYBERTECH series,

improved access in confined spaces, with a large working envelope and reduced disruptive contours

* Every installation position possible: Floor, ceiling, wall, any angle

* Appropriately dimensioned and robust joints, gear units and motors – suitable for applications such as handling, assembly,

palletizing, arc welding

* Simple and standardized mounting of process equipment on axis 3 of all KR CYBERTECH nano robots with hollow wrist

* Infinitely rotating axis 6 and hollow wrist with bearings on one side – more flexible positioning of the robot and process

equipment

improved access in confined spaces, with a large working envelope and reduced disruptive contours

* Every installation position possible: Floor, ceiling, wall, any angle

* Appropriately dimensioned and robust joints, gear units and motors – suitable for applications such as handling, assembly,

palletizing, arc welding

* Simple and standardized mounting of process equipment on axis 3 of all KR CYBERTECH nano robots with hollow wrist

* Infinitely rotating axis 6 and hollow wrist with bearings on one side – more flexible positioning of the robot and process

equipment

Fast time to production

* Industry-leading delivery times – 8 weeks for standard, 3 weeks for Ready Packs

* In-stock Ready Packs of most popular variants

* In-stock Ready Packs of most popular variants

Low maintenance effort and reduced downtime

* Complete a motor change without changing the oil– oil chambers are sealed on the motor side

* Long intervals between oil changes – up to 20 000 hours

* Standard cable set is maintenance free and shielded from electromagnetic radiation

* Long intervals between oil changes – up to 20 000 hours

* Standard cable set is maintenance free and shielded from electromagnetic radiation

High performance

* High velocities and fast acceleration

* Fast cycle times

* Fast cycle times

About KUKA

Robot systems from KUKA

KUKA offers industrial robots in a wide range of versions with various payload capacities and reaches for almost any application, also in your industry.

KUKA production systems

We advise, plan and develop the appropriate process for your factory - depending on the requirement we deliver individual components, cells or complete turnkey systems

Autonomous mobile robotics

Autonomous mobile robots and mobile platforms for flexible automation: sensor technology, no-code programming, state-of-the-art battery technology, all payloads.

Process technologies

From special welding processes to soldering and other joining techniques, you will find descriptions of all the KUKA process technologies here.

Contact US

Hot Searches