- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

1000 KG

-

Keyword:

-

Hammer Crusher Mill Hammer Crusher

-

Applicaton:

-

Rock Crusher Processing

-

Raw material:

-

Stones Rocks Ores

-

Color:

-

Customer Requirement

-

Feeding size:

-

Customer Requirement

-

Other name:

-

Grinder, Crushing machine, Crushing mill

-

Spare parts supply:

-

12 Months Guarantee

-

Advantage:

-

High Efficiency Low Energy

-

Usage:

-

Mining Crushing Stone Crusher

Quick Details

-

Application:

-

stone,ore,coal,sand

-

Capacity(t/h):

-

According to different models

-

Place of Origin:

-

HEN

-

Dimension(L*W*H):

-

Depend on model

-

Weight:

-

1000 KG

-

Keyword:

-

Hammer Crusher Mill Hammer Crusher

-

Applicaton:

-

Rock Crusher Processing

-

Raw material:

-

Stones Rocks Ores

-

Color:

-

Customer Requirement

-

Feeding size:

-

Customer Requirement

-

Other name:

-

Grinder, Crushing machine, Crushing mill

-

Spare parts supply:

-

12 Months Guarantee

-

Advantage:

-

High Efficiency Low Energy

-

Usage:

-

Mining Crushing Stone Crusher

|

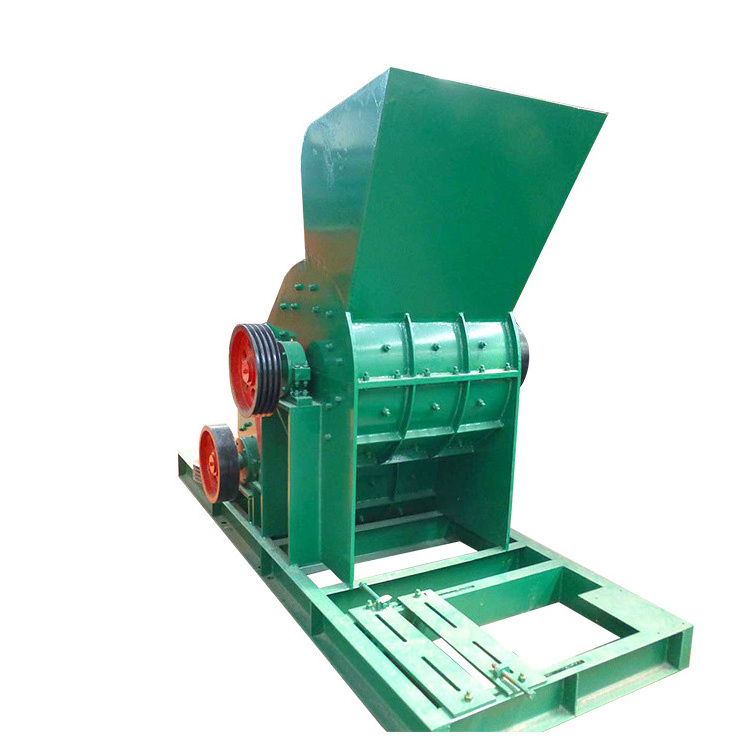

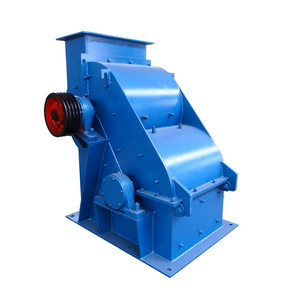

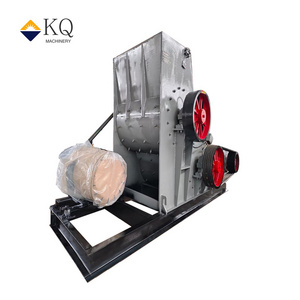

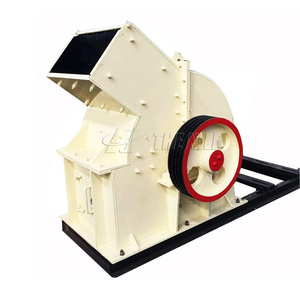

Double rotor ultra fine gangue crusher/ double stage hammer crusher

|

|

|

|

|

||||

Product Description

1. Introduction of two stage hammer crusher

The two-stage crusher also called the coal pulverizing mill is a new type of patent product for utility models which can easily break materials with high moisture content such as gangue, shale and coal cinder etc. Two-stage crusher is used in the industries such as construction, chemical engineering, metallurgy, mine, ceramics and refractory matter. The two-stage crusher can be regarded as the combination of two hammer crushers. It adopts two sets of rotors to work together.

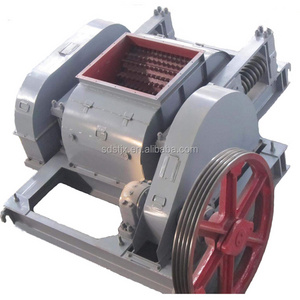

2.Working principle of two stage hammer crusher:

The motor drives the rotor rotates of the Hammer Crusher at a high speed through the belt, and on the rotor there are series hammers. When the materials get into the working area of hammers, they are crushed by the rotating hammers of

The Hammer Crusher with high rotation speed, the products which are crushed to meet the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushed area by the hammers of the Hammer Crusher for being re-crushed until they reached the required size.

3. Characteristics of the Equipment:

1).The output particle size below 3 mm and below 2 mm accounts for more than 90%. Uniform particle adjustable, especially suitable for the production of porous brick, thin-walled brick.

1).The output particle size below 3 mm and below 2 mm accounts for more than 90%. Uniform particle adjustable, especially suitable for the production of porous brick, thin-walled brick.

2).Double - rotor two - stage grinding, not grate mesh, wet material does not plug.

3).Hammer head, liner bidirectional clearance, at any time to control the size of the discharge.

4).Double shaft and double flying wheel, stable operation, high inertia, power saving more than 20%.

5).With its own hydraulic lifting device, the replacement of hammerhead maintenance saves time and eff

3).Hammer head, liner bidirectional clearance, at any time to control the size of the discharge.

4).Double shaft and double flying wheel, stable operation, high inertia, power saving more than 20%.

5).With its own hydraulic lifting device, the replacement of hammerhead maintenance saves time and eff

Size Information

|

Type specification

|

Weight(T)

|

Output(t/h)

|

The number of hammerhead

(PCS)

|

The hammerhead weight(KG/PC)

|

Motor type(KW)

|

Disharging granularity

(mm)

|

|

2PC-600*400

|

1

|

10-15

|

24

|

3.5

|

18.5+18.5

|

2-3

|

|

2PC-600*600

|

1.3

|

15-20

|

40

|

3.5

|

22+22

|

2-3

|

|

2PC-600*800

|

1.8

|

20-30

|

48

|

3.5

|

30+22

|

2-3

|

|

2PC-800*600

|

3

|

30-40

|

40

|

7

|

45+37

|

2-3

|

|

2PC-800*800

|

3.5

|

40-50

|

48

|

7

|

55+45

|

2-3

|

|

2PC-1000*800

|

5.5

|

50-60

|

48

|

8

|

55+75

|

2-3

|

|

2PC-1000*1000

|

7

|

60-90

|

52

|

8

|

90+75

|

2-3

|

|

2PC-1000*1200

|

8

|

70-90

|

56

|

8

|

110+90

|

2-3

|

|

2PC-1000*1400

|

8.5

|

100-120

|

60

|

10

|

110+132

|

2-3

|

|

2PC-1200*1400

|

9

|

120-130

|

60

|

12

|

132+160

|

2-3

|

|

2PC-1400*1600

|

13

|

130-180

|

72

|

20

|

160+200

|

2-3

|

Customer site

Customer visit

Hot Searches