Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Building,Construction,Deaoration

-

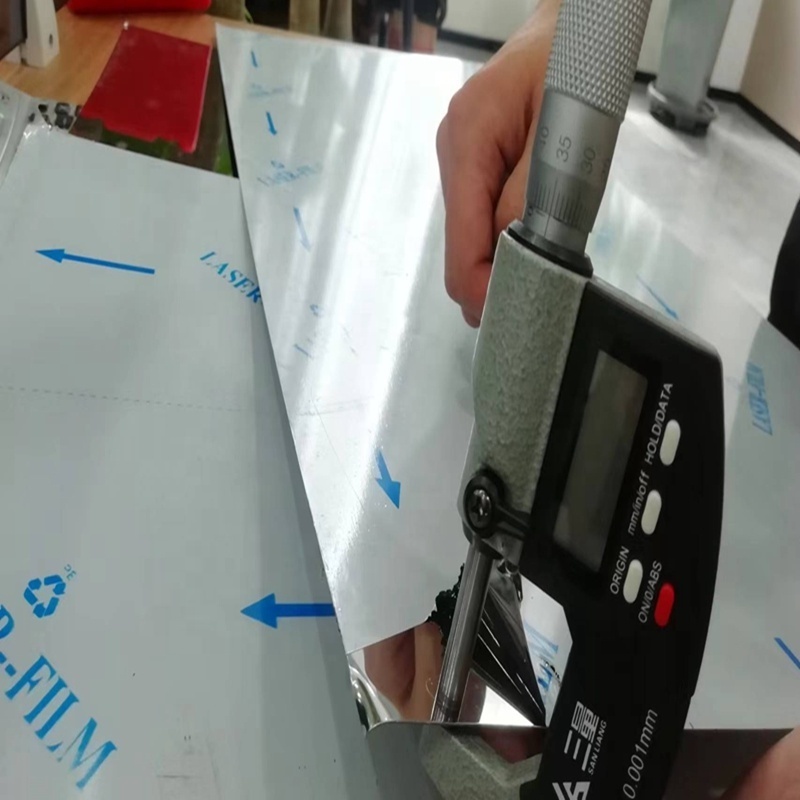

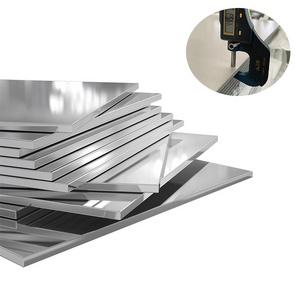

Thickness:

-

0.2-100mm, 0.2-100mm

-

Width:

-

100-2000mm

-

Product Name:

-

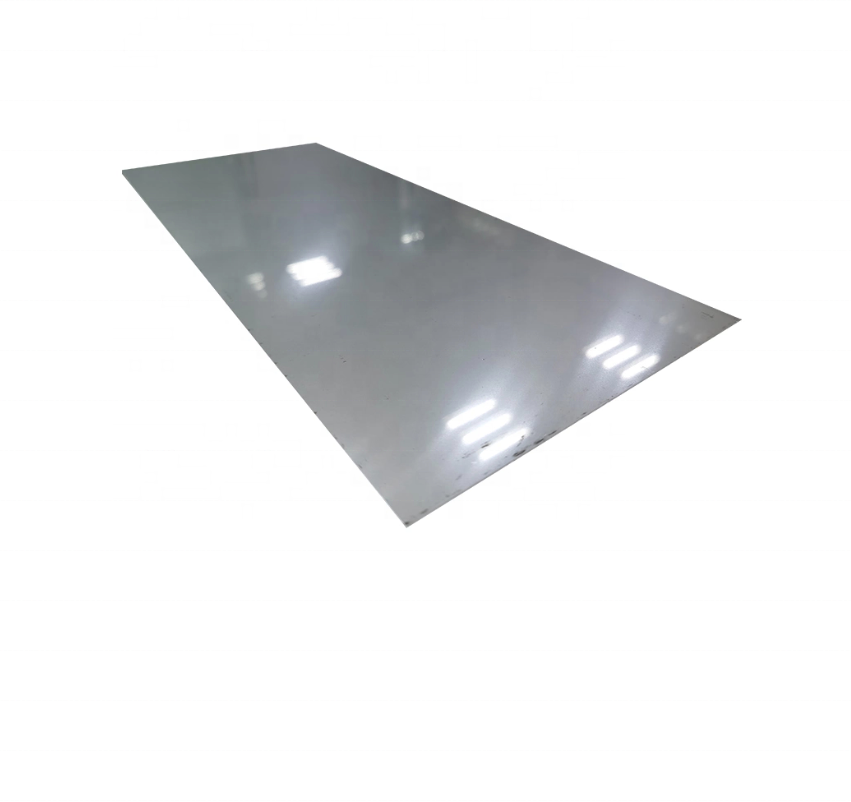

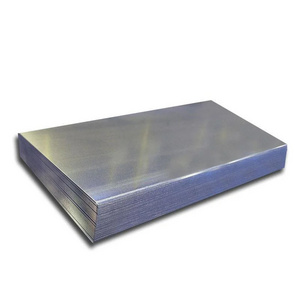

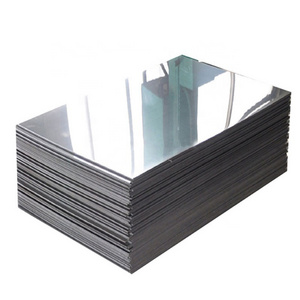

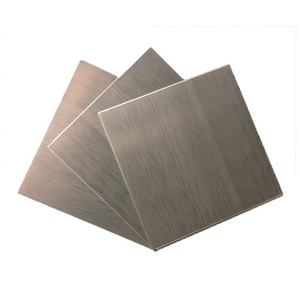

Stainless Steel Sheet/Plate

-

Sample:

-

Free-sample

-

MOQ:

-

1Ton

-

Technique:

-

Hot/Cold Rolled

-

Shape:

-

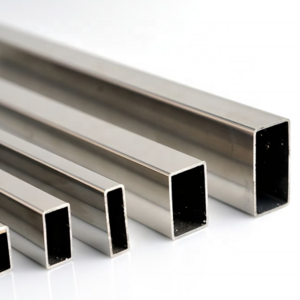

Flat.sheet.coil.plate

-

Port:

-

Qingdao,Tianjin,Shanghai

-

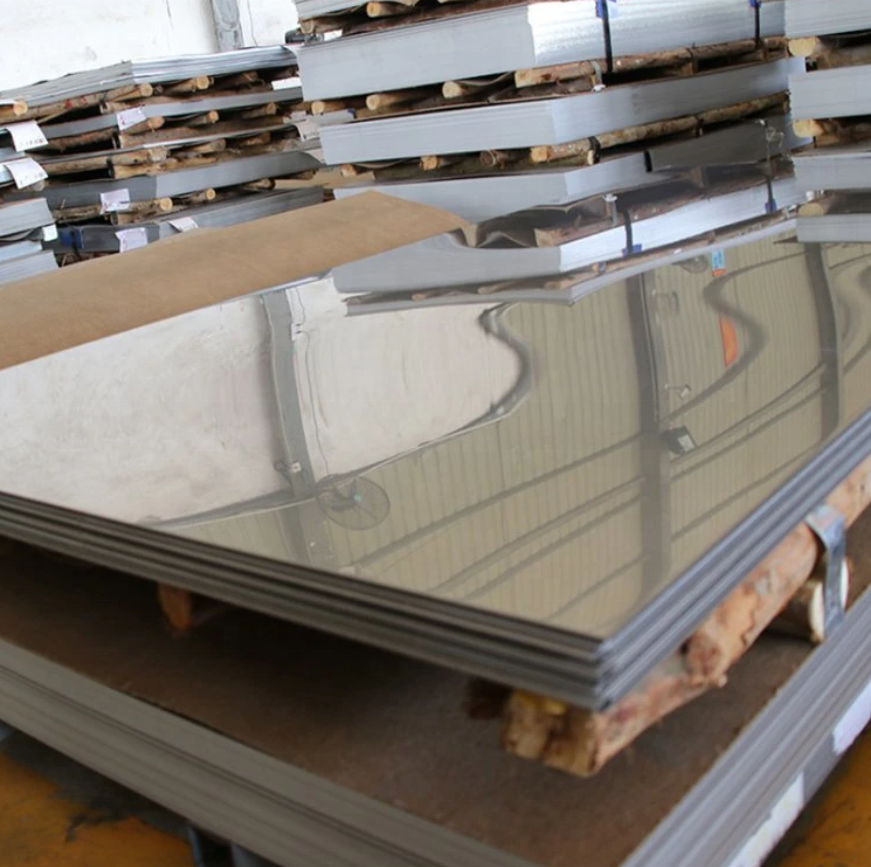

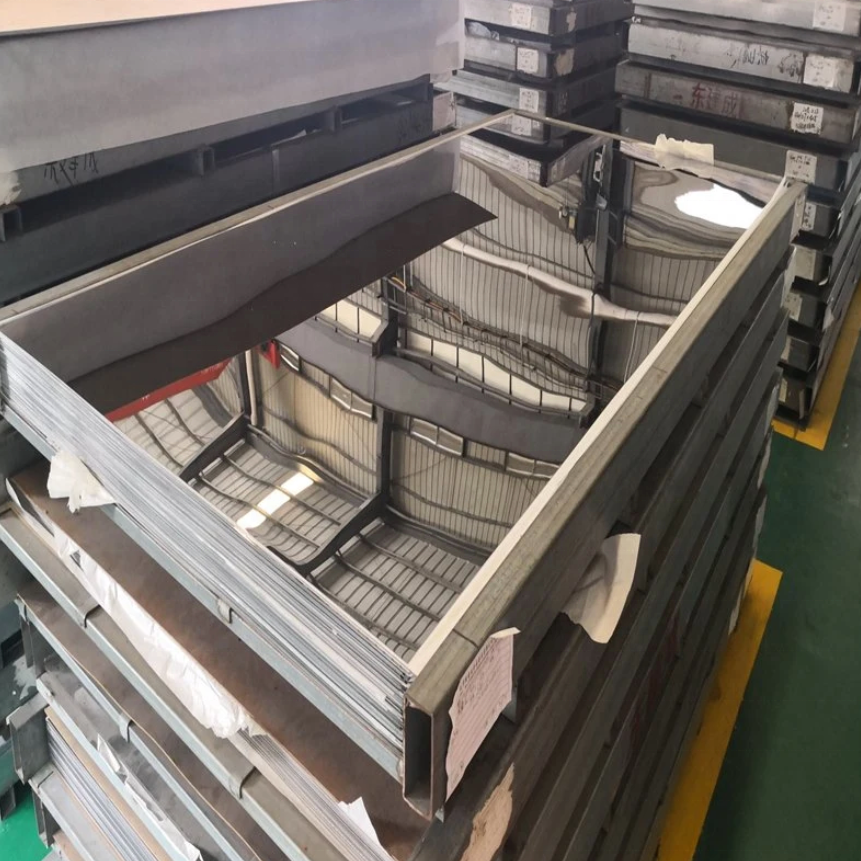

Packing:

-

Standard Sea-worthy Packing

Quick Details

-

Surface Finish:

-

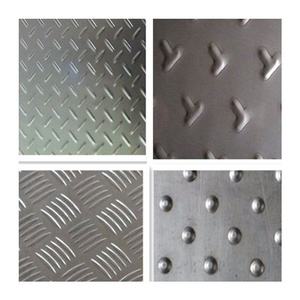

2B No.4 BA NO.1 HL 8K, 2B/BA/HAIRLINE/8K/NO.4/No.1

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Wanteng

-

Application:

-

Building,Construction,Deaoration

-

Thickness:

-

0.2-100mm, 0.2-100mm

-

Width:

-

100-2000mm

-

Product Name:

-

Stainless Steel Sheet/Plate

-

Sample:

-

Free-sample

-

MOQ:

-

1Ton

-

Technique:

-

Hot/Cold Rolled

-

Shape:

-

Flat.sheet.coil.plate

-

Port:

-

Qingdao,Tianjin,Shanghai

-

Packing:

-

Standard Sea-worthy Packing

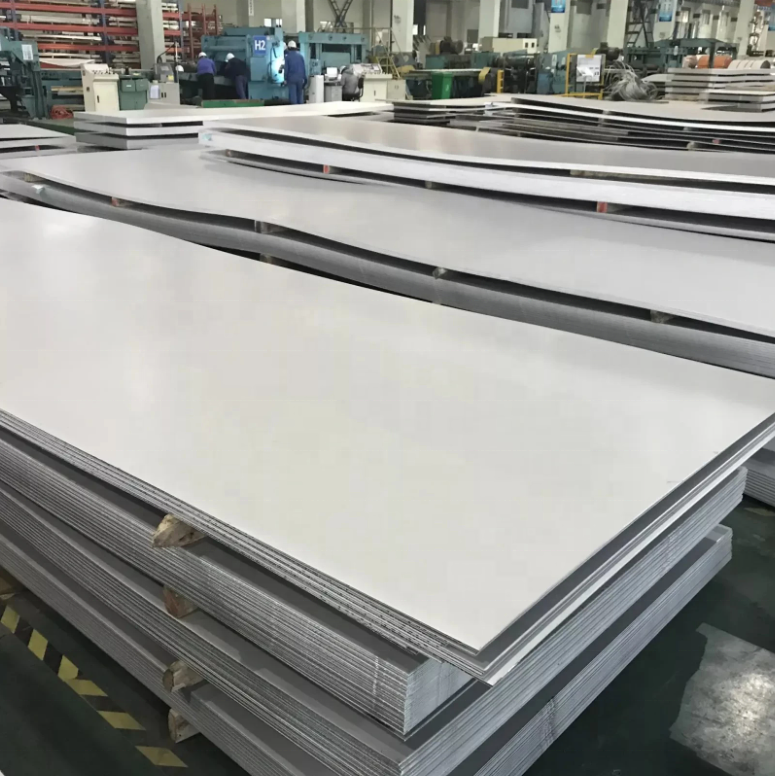

Product Description

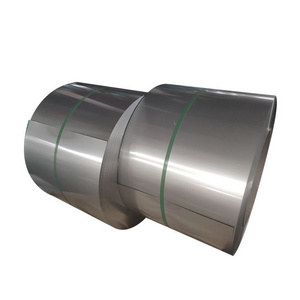

Stainless steel Coil

is often referred to as 'corrosion-resistant steel' - it does not stain, corrode or rust as easily as normal carbon steel. It would however be misleading to say it is corrosion-proof. It differs significantly from standard carbon steel due to the amount of chromium present, which limits surface corrosion unlike carbon steel which will rust when exposed to air and any moisture in the atmosphere. Due to its anti-oxidation qualities, stainless steel is often a

popular solution

.

|

Product

|

Stainless Steel Sheet/Plate/Coil

|

|

Surface Finish

|

BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, Embossed

|

|

Technique

|

Hot Rolled / Cold Rolled

|

|

Standard

|

GB JIS ASTM ASME EN

|

|

Steel Grade

|

200 series: 201 202

|

|

|

300 series: 301 304 304L 309 310 310s 316 316L 321

|

|

|

400 series: 409 410 410S 420 430

|

|

Color

|

Standard RAL color:red,bule,white,grey,brick,etc.

|

|

Stock Dimension

|

0.5mm-4mm x 1220mm/1500mm x 2440mm/2500mm; 5mm-25mm x 1220mm/1500mm x 2440mm/2500mm/6000mm;

|

|

|

8mm-80mm x 1500/1800/2000mm/2500 x 6000mm;

|

|

|

Cut to size according to customers' demands

|

|

Service

|

OEM, customized processing service, customized fabrication by drawings

|

|

Processing Type

|

Cutting, bending,stamping,welding,cnc machining

|

|

Cutting Type

|

Laser cutting;water-jet cutting;flame cutting

|

|

Protection

|

1. Inter paper available

|

|

|

2. PVC protecting film available

|

|

Application

|

Costruction Industry/Kichten Products/Fabrication Industry/Home Decoration

|

300 series alloys

are most commercially used worldwide. Grade 304 and 316 are popular alloys of the 300 series. It is an austenitic

high chromium-nickel, corrosion-resistant alloy

. The presence of molybdenum improves corrosion resistance in acidic mediums. It has

considerable strength, heat resistance, corrosion resistance, and performs well at sub-zero temperature

.

300 series has

excellent weldability and formability

. 300 series applications are vast and commercial. It is mainly used in the

food processing industry, kitchenware and appliances, heat-exchangers, chemical containers, water filtration systems, and architectural paneling

.

|

Comparasion of Stainless Steel 200, 300 & 400 series

|

|

|

|

|

|

|

||||||

|

Series

|

Composition

|

Corrosion Resistance

|

Magnetism

|

Ductility

|

Resistance at low Temp

|

Weldability

|

||||||

|

200

|

Austenitic (chromium-manganese alloys)

|

Lower than 300 series grade, but better than 400 series

|

Absent

|

Lower than 300 series grades but better than 400 series

|

Lower than 300 series grades

|

Good, but Lower than 300 series grades

|

||||||

|

300

|

Austenitic (chromium-nickel alloys)

|

High

|

Absent

|

Very ductile

|

Excellent

|

Excellent

|

||||||

|

400

|

Ferritic and martensitic chromium alloys

|

Lower than 300 series grades

|

Present

|

Lower than 300 series grades

|

Poor

|

Lower than 300 series grades

|

||||||

Specification

Stainless Steel 300 Series Chemical Composition

Application

The 300 series consist of austenitic chromium-nickel alloys. Austentic contains a maximum of 0.15% carbon and a minimum of 16% chromium, and nickel is the important alloying element. This creates superior corrosion resistance and ease of fabrication. Austentic stainless steel has a wide range of mechanical properties and can withstand a wide range of temperatures. Austenitic grades are the most commonly used stainless steels, and are not hardenable by heat treatment.

Packing & Delivery

Hot Searches