- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Automatic Metal Polishing Machine

-

Application:

-

Surface Polishing

Quick Details

-

Place of Origin:

-

China

-

Power (kW):

-

1.5

-

Weight (KG):

-

200

-

Product name:

-

Automatic Metal Polishing Machine

-

Application:

-

Surface Polishing

Products Description

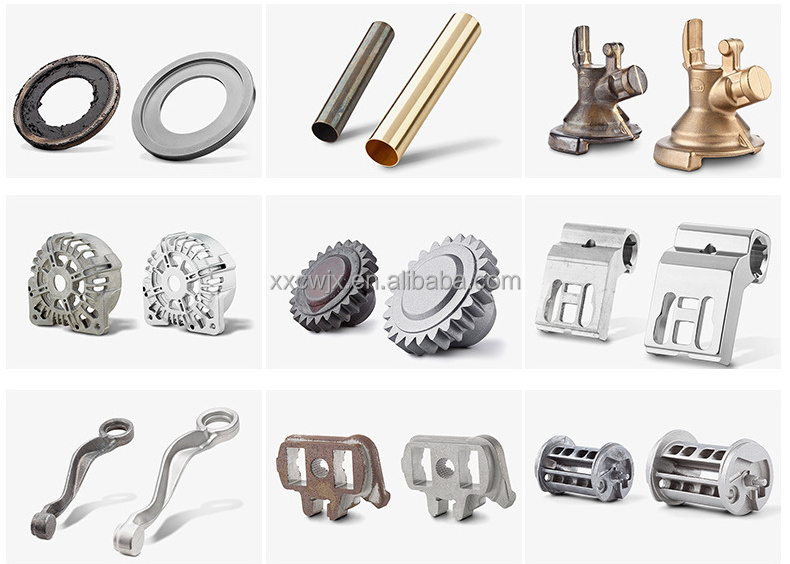

Custom Stainless Steel Metal Part Vibration Grinding And Tumbler Polishing Metal Vibratory Deburring Finishing Machine

Size information

|

Volume

|

Diameter

|

Motor

|

Weight

|

Dimension(L*W*H)

|

|

(L)

|

(mm)

|

(kw)

|

(kg)

|

(mm)

|

|

CW-30

|

500

|

0.25

|

60

|

500*500*550

|

|

CW-60

|

640

|

0.75

|

80

|

640*640*660

|

|

CW-80

|

800

|

1.1

|

120

|

800*800*700

|

|

CW-150

|

1050

|

1.5

|

300

|

1050*1050*820

|

|

CW-200

|

1220

|

2.2

|

400

|

1220*1220*820

|

|

CW-300

|

1350

|

3.7

|

500

|

1350*1350*1020

|

|

CW-400

|

1450

|

3.7

|

600

|

1450*1450*1050

|

|

CW-600

|

1850

|

5.5

|

1000

|

1850*1850*1220

|

Why Choose Us

1. Customizable size

Suitable for the finishing and surface treatment of metal and non-metal material parts with medium and small structural sizes in mass production.

2. Good processing effect

Effectively remove burrs, burrs, burrs, burrs, edges, edges, rust, stains, oil stains, oxide scales, and marks on the surface of parts, achieving a certain level of smoothness, smoothness, and brightness.

3. Good restoration effect

During the polishing process, it will not damage the original dimensions and accuracy of the parts, and can significantly improve the surface roughness of the parts.

4. High degree of automation

Can achieve automated operations, and can randomly check the processing status of part surfaces at any time. The flat bottomed and straight mouth vibration polishing machine equipment is equipped with a feeding port and a water outlet, and the straight mouth with discharge and bending ports has an automatic separation function for abrasives and products.

5. Using high-quality materials

The vibration container does not use the previously non wear-resistant black rubber material, but instead uses a one-time cast high wear-resistant PU adhesive (polyurethane) material, which improves the service life of the lining by more than 5 times, while avoiding collision between parts and reducing noise generation.

6. Free polishing of samples

We can provide customers with free process samples of product parts to determine the selection of a reasonable and cost-effective grinding and polishing process (including equipment selection, selection of grinding and polishing auxiliary materials, etc.), and provide lifelong maintenance and technical support for equipment.

Application

Vibration metal parts surface polishing is suitable for surface finishing of metal or non-metal workpieces, including deburring, chamfering, and rust removal oxide layer. In many production and processing industries such as machinery, electronics, instrumentation, space navigation, automobiles, motorcycles, hardware, handicrafts, etc., surface treatment before electroplating or chemical processing is carried out.

Machine Show

Our Service

Our Company

Xinxiang Chenwei Machinery Co., Ltd. is an innovative enterprise that integrating technology R&D, processing, manufacturing and trade services. Our company is mainly devoted ourselves to the design, fabrication and installation of screening, conveying, mixing, crushing and other related products.

FAQ

Q1. Are you trading company or manufacturer?

A: We're manufacturer. We have our own factory and experienced technicians

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery and delivery time?

A: EXW, FOB, CFR, CIF, DDU, etc.Generally, it will take 7 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Hot Searches