[Warm edge strip] is a spacer strip with a lower thermal coefficient than aluminum spacer strips. It is made of polymer composite materials and stainless steel materials to form a cavity. It is used to fill desiccant, isolate the original insulating glass piece, and act as a supporting structural product. The purpose is to make the glass form a broken bridge.

Warm edge strips can effectively weaken the thermal bridge effect of windows, maintain appropriate temperatures on both sides of the glass, and improve the overall thermal insulation and energy-saving performance of the glass. At the same time, they can effectively inhibit the formation of condensation water and prevent mold from growing between the glass and the window frame; This enables insulated glass products to have better performance, longer service life, no gas in the hollow layer to escape, and more glass shapes.

"Warm edge strips" are spacers with a lower thermal coefficient than aluminum spacers. They are made of composite materials and stainless steel materials to form a cavity. They are used to fill desiccant, isolate the original insulating glass sheets, and are structural products that play a supporting role.

Insulated glass warm edge strips have high-level sealing, high-quality stability, and excellent warm-edge performance. Added to insulating glass with higher thermal insulation requirements, the overall thermal insulation and energy-saving performance of the glass is even better.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

REGAL

-

Model Number:

-

12A

-

Type:

-

Warm edge spacer bar

-

Material:

-

Aluminum

-

Export length:

-

5M

-

Surface treatment:

-

High Frequency welding

-

Product name:

-

Warm edge spacer bar

-

Size:

-

11.5x6.5x0.25mm

-

Function:

-

Corrosion resistance, high strength, oxidation resistance

-

Alloy:

-

stainless steel

-

MOQ:

-

1 carton

-

Usage:

-

Insulating glass and windows

-

Packing:

-

Carton

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, total solution for projects

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

REGAL

-

Model Number:

-

12A

-

Type:

-

Warm edge spacer bar

-

Material:

-

Aluminum

-

Export length:

-

5M

-

Surface treatment:

-

High Frequency welding

-

Product name:

-

Warm edge spacer bar

-

Size:

-

11.5x6.5x0.25mm

-

Function:

-

Corrosion resistance, high strength, oxidation resistance

-

Alloy:

-

stainless steel

-

MOQ:

-

1 carton

-

Usage:

-

Insulating glass and windows

-

Packing:

-

Carton

Product Description

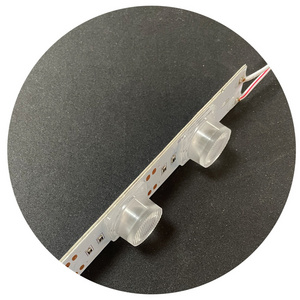

Insulating glass warm spacer bar

①Rustless, corrosion, high brightness.

②Surface evenly, straightness, and no deformation and dimensional stability.

③Connected by only one straighter, good sealing with long lifetime.

④limit deviation of peripheral wall thickness is ±0.025mm.

②Surface evenly, straightness, and no deformation and dimensional stability.

③Connected by only one straighter, good sealing with long lifetime.

④limit deviation of peripheral wall thickness is ±0.025mm.

High strength, high toughness,

Continuously bent to any angle ends the device aluminum frame.

The vents are well placed.

To ensure molecular activity sieves, guaranteed and various types

Adhesive with excellent adhesion.

Details Images

STAINLESS STEEL SPACERS ADVANTAGES

1.Excellent fire performance

The melting point of stainless steel is around 1500 0 C. The stainless steel spacer can ensure the integrity of the glass structure under the condition of high temperature and high temperature. It is the best choice for fireproof windows and fireproof glass.

2.Outstanding warm edge performance

The thermal conductivity of stainless steel warm edge spacer is 14.3 w/m. K, which is less than 9 parts of aluminum spacer, so it is a warm edge spacer.

3.Reliable sealing structure

The linear expansion coefficient of stainless steel spacer is 15.7, which is the closest to the linear expansion coefficient of glass.According to the US Sealed Insulating Glass Association (SIGMA) for 15 years of tracking statistics on insulating glass, the industry average failure rate is more than 8%, while the 20-year failure rate of insulating glass with stainless steel warm-edged spacers is only 0.5%.

4.Stable chemical properties

As an inorganic material, stainless steel has stable chemical properties under the action of ultraviolet light and high

temperature, no chemical volatilization, and does not react with the soft coating of off-line low-emissivity glass.

5.Superior mechanical properties

The stainless steel spacer can provide the rigidity and structural strength required for public building insulating glass. It can be used not only for residential doors and windows but also for structural curtain wall glass, large plate insulating glass, high-rise buildings and places with high wind loads.

The melting point of stainless steel is around 1500 0 C. The stainless steel spacer can ensure the integrity of the glass structure under the condition of high temperature and high temperature. It is the best choice for fireproof windows and fireproof glass.

2.Outstanding warm edge performance

The thermal conductivity of stainless steel warm edge spacer is 14.3 w/m. K, which is less than 9 parts of aluminum spacer, so it is a warm edge spacer.

3.Reliable sealing structure

The linear expansion coefficient of stainless steel spacer is 15.7, which is the closest to the linear expansion coefficient of glass.According to the US Sealed Insulating Glass Association (SIGMA) for 15 years of tracking statistics on insulating glass, the industry average failure rate is more than 8%, while the 20-year failure rate of insulating glass with stainless steel warm-edged spacers is only 0.5%.

4.Stable chemical properties

As an inorganic material, stainless steel has stable chemical properties under the action of ultraviolet light and high

temperature, no chemical volatilization, and does not react with the soft coating of off-line low-emissivity glass.

5.Superior mechanical properties

The stainless steel spacer can provide the rigidity and structural strength required for public building insulating glass. It can be used not only for residential doors and windows but also for structural curtain wall glass, large plate insulating glass, high-rise buildings and places with high wind loads.

Specification

|

Product Name

|

Insulating Glass Aluminum Warm edge Spacer Bar

|

|

Material

|

Stainless steel

|

|

Width

|

8-24MM

|

|

MOQ

|

1000meters

|

|

Package

|

carton

|

|

Payment term

|

T/T , L/C and negotiated

|

|

Delivery time

|

5-15 working days

|

|

Used

|

Insulating glass making

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Why Choose Us

There are 7 production lines for Insulating glass warm spacer bars,specifications including 6A-27A.At present, the insulating glass stainless steel Insulating glass warm spacer bars designed and developed by our company is the first

one to be produced by advanced laser welding technology in China. The product has high strength and good thermal performance, and is especially suitable for building doors and windows, large plate insulating glass, high-rise building glass curtain wall and other occasions.

one to be produced by advanced laser welding technology in China. The product has high strength and good thermal performance, and is especially suitable for building doors and windows, large plate insulating glass, high-rise building glass curtain wall and other occasions.

Hot Searches