- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Voltage:

-

220V/380V, 50HZ (3 phase)

-

Power:

-

5-7kw

-

Dimension(L*W*H):

-

1600*1400*1550mm

-

Weight:

-

800 kg

-

Marketing Type:

-

Hot Product

-

Product Name:

-

Hydraulic Pulper

-

Raw Material:

-

Recycled Paper

-

Speed:

-

Once every 8-10 minutes

-

Color:

-

Green, Blue or Customized

-

Function:

-

Pulverize paper pulp plate, broken paper, waste paper and so on

-

Certification:

-

CE

-

Advantage:

-

High Effiency and Easy Operation

-

Model:

-

Five Types

-

Feature:

-

100 % Recyclable

-

Size:

-

Can Customize

Quick Details

-

Production Capacity:

-

1-10 tons/h

-

Product Type:

-

Pulping Machine

-

Processing Type:

-

Waste Paper Pulper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Voltage:

-

220V/380V, 50HZ (3 phase)

-

Power:

-

5-7kw

-

Dimension(L*W*H):

-

1600*1400*1550mm

-

Weight:

-

800 kg

-

Marketing Type:

-

Hot Product

-

Product Name:

-

Hydraulic Pulper

-

Raw Material:

-

Recycled Paper

-

Speed:

-

Once every 8-10 minutes

-

Color:

-

Green, Blue or Customized

-

Function:

-

Pulverize paper pulp plate, broken paper, waste paper and so on

-

Certification:

-

CE

-

Advantage:

-

High Effiency and Easy Operation

-

Model:

-

Five Types

-

Feature:

-

100 % Recyclable

-

Size:

-

Can Customize

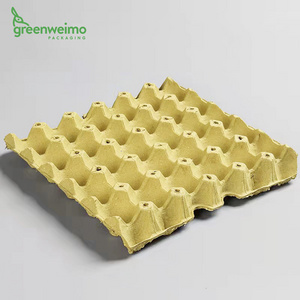

Product Description

The

hydraulic pulper

is an essential accessory equipment for the egg tray production line. Its purpose is to crush waste paper, mix water with old books, old magazines, damaged cartons, etc. to make pulp. This is the first step in egg tray production.

Product Details

Production Process

There are many different models of hydraulic pulper, according to the output size of egg tray production line to determine the most suitable model. The machine can customize different colors according to customer requirements, which will not charge extra fees.

Working Principle

1. Crushed fiber bundles and wet pulp blocks by the rolling of rotor and rotating blades ;

2. Rotating blades produce a strong vortex and formed a high speed cyclone zone around the blade, the speed of the pulp are slow down with the gap increase between this region ,so that the pulp layer formed a speed difference, and the fibers separated because of the friction;

3. Fiber bundles are separated by rub against each other in the gap of the blade and sieve separation, then good pulp out the pulper through sieve hole;

4. The sand, nails and other precipitation debris are accumulation in the miscellaneous mouth of the pulper.; The pulper blademade by stainless steel casting or steel production, and imported brands bearing.

Packing & Delivery

Hot Searches