Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

zrfx

-

Model Number:

-

RY32-32-160

-

Place of Origin:

-

China

-

Horsepower:

-

2.04HP

-

Outlet Size:

-

32mm

-

Power:

-

1.5KW

-

Product name:

-

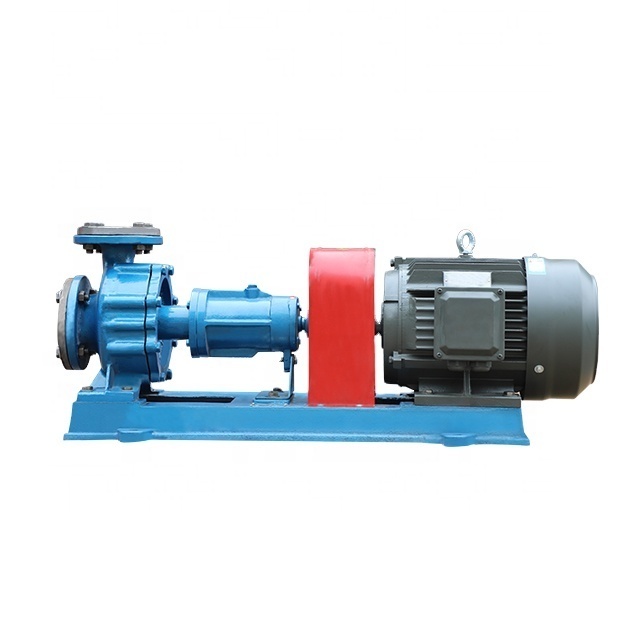

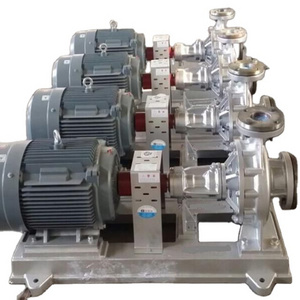

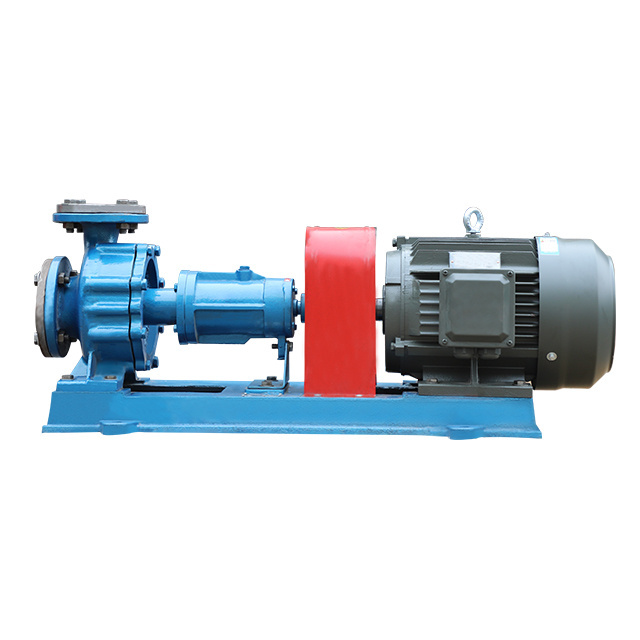

RY thermal oil pump

-

Material:

-

Cast steel

-

Motor:

-

100% Copper Wire

-

Speed:

-

2900r/min

-

Sealing method:

-

Packing seal

-

Motor power:

-

1.5kw

-

MOQ:

-

1 Set

-

Standard or Nonstandard:

-

Standanrd

-

Frequency:

-

50 Hz

Quick Details

-

Application:

-

Other, Automotive Industry, Biofuel Industry, Commercial Buildings, District Energy, Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Machining, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry

-

Pressure:

-

Other

-

Voltage:

-

380V, 380V

-

Warranty:

-

1 years

-

Brand Name:

-

zrfx

-

Model Number:

-

RY32-32-160

-

Place of Origin:

-

China

-

Horsepower:

-

2.04HP

-

Outlet Size:

-

32mm

-

Power:

-

1.5KW

-

Product name:

-

RY thermal oil pump

-

Material:

-

Cast steel

-

Motor:

-

100% Copper Wire

-

Speed:

-

2900r/min

-

Sealing method:

-

Packing seal

-

Motor power:

-

1.5kw

-

MOQ:

-

1 Set

-

Standard or Nonstandard:

-

Standanrd

-

Frequency:

-

50 Hz

1、 Overview of ry hot oil pump

Lqry series hot oil pump has been widely used in the heating system of heat carrier in China. It has entered various industrial fields such as petroleum, chemical industry, rubber, plastics, pharmaceutical, textile, printing and dyeing, road building, food and other industrial fields. It is mainly used to transport weakly corrosive high-temperature liquid without solid particles. The operating temperature is ≤ 370 ℃. It is an ideal hot oil circulating pump.

2、 The significance of the model of ry hot oil pump

|

fault

|

reason

|

Exclusion method

|

|

The pump does not output liquid (medium) or output little liquid

|

Output pipeline resistance, impeller blockage, low speed, wrong steering. Suction line valve not open

|

Reduce tube resistance. Remove foreign matter from impeller. Increase the speed and adjust the steering. Open the valve

|

|

|

The pump shaft is not concentric with the motor. The bearing is damaged. The oil pump bears the weight of the pipeline. There is

air in the pipeline |

Adjust the axis of pump and motor center and replace the bearing. Adjust the installation position of the pipeline. Remove the air

from the pipeline |

|

|

The impeller is blocked and the speed is not enough. The characteristic curve of the device is not consistent with that of the

pump. The clearance of sealing ring is too large and there is leakage in the pipeline |

Remove the foreign matter in the impeller and increase the speed. Adjust the characteristics of the device, replace the impeller,

check the installation quality of the pipeline and correct it |

|

Excessive power consumption of oil pump

|

The rotor part of the friction, pump axis and motor axis does not coincide. The flow of the pump is too high

|

Adjust the axis of the pump to coincide with the axis of the motor, and close the outlet valve to reduce the flow

|

|

The rotor part of the oil pump is hot or does not rotate

|

Foreign matter mixed into the pump, stuck, poor lubrication conditions, resulting in shaft report

|

Remove the foreign matter in the pump and replace the bearing

|

|

|

The bearing lacks oil lubrication or the selection of lubricating oil is unreasonableand the axis of pump and motor is not concentric

|

Add clean heat transfer oil to the bearing cavity, use grease reasonably, and adjust the center line of motor and pump

|

1、 Product name and model ① caliber ② lift ③ motor power ④ flow rate ⑤ rotational speed ⑥ voltage ⑦ suction lift and medium, whether with accessories, so that we can correctly select the type for you

2、 If the product model of our company has been selected by the design unit, please send it to Shandong East Pump Company for purchase.

3、 When the use environment is very important or complex, please provide the design drawings and detailed parameters as far as possible, and the technical experts of our company will check for you.

Product price attribute is for reference only, please call Wangwang for details!

Hot Searches