- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/Customized

-

Power:

-

8 KW

-

Dimension(L*W*H):

-

5000mm X 900mm X1800mm

-

Weight (KG):

-

1800

-

Product name:

-

Automatic Plastic Film Laminating Machine

-

Max laminating width:

-

330mm

-

Base Material:

-

PVC Flim

-

Name:

-

Automatic Film Laminator Machine

-

Function:

-

Press Film

-

Keyword:

-

Auto Laminator

-

Model:

-

Flute Laminator 1300H

-

Usage:

-

Wide Usage

-

Type:

-

Smart Laminating Machine

-

Control panel function:

-

LED Lighting

Quick Details

-

Place of Origin:

-

Anhui, China

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

POLYSUN

-

Voltage:

-

380V/220V/Customized

-

Power:

-

8 KW

-

Dimension(L*W*H):

-

5000mm X 900mm X1800mm

-

Weight (KG):

-

1800

-

Product name:

-

Automatic Plastic Film Laminating Machine

-

Max laminating width:

-

330mm

-

Base Material:

-

PVC Flim

-

Name:

-

Automatic Film Laminator Machine

-

Function:

-

Press Film

-

Keyword:

-

Auto Laminator

-

Model:

-

Flute Laminator 1300H

-

Usage:

-

Wide Usage

-

Type:

-

Smart Laminating Machine

-

Control panel function:

-

LED Lighting

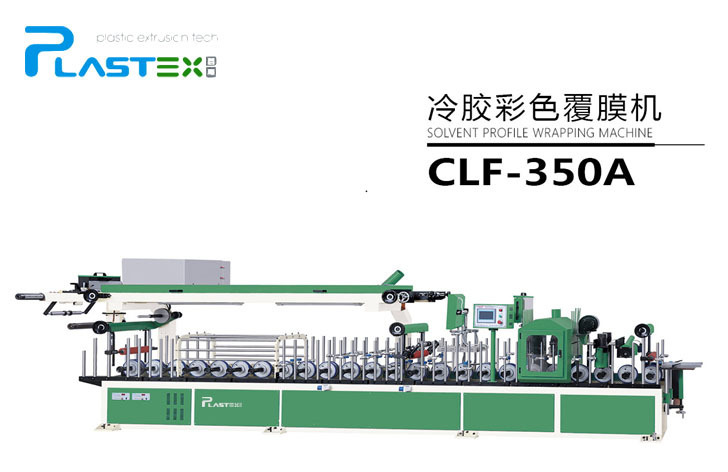

Technical Parameters

|

Power voltage

|

380V 50HZ

|

|

Film Height

|

125mm

|

|

Total Power

|

8 KW

|

|

Laminating Speed

|

0-15m/min

|

|

Driving Power

|

1.5 KW

|

|

Dimension

|

5000mm X 900mm X1800mm

|

|

Film Width

|

20-300 mm

|

|

|

|

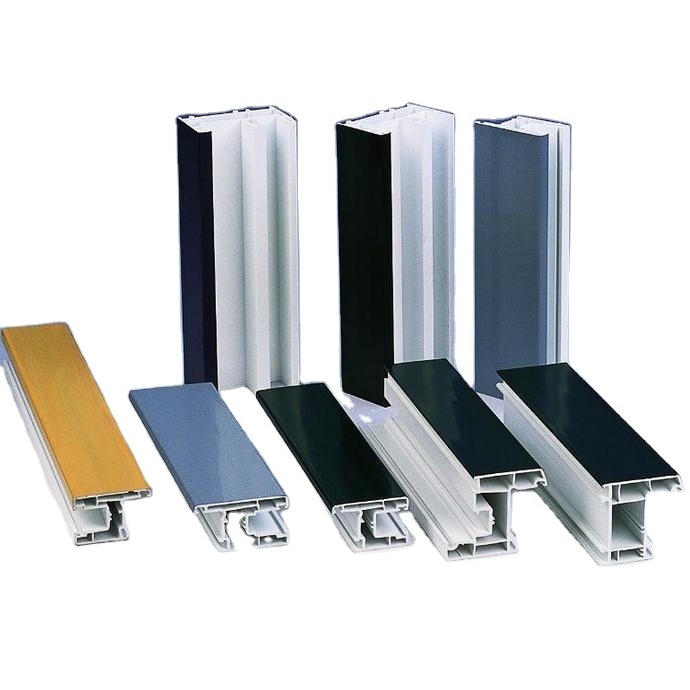

PRODUCT OVERVIEW

Profile Wrapping Machine

Our machine is suitable for

indoor profile,like

PVC, wood plastic, aluminum, wood, glass fiber reinforced plastic surface coating.Polyurethane solvent-based glue is coated by the machine, and the glue coating system adopts the scraping method.

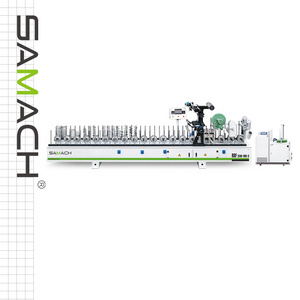

Components

Our machine is composed of fan dust removal, profile preheating, automatic gluing, covering protective film.

Our machine adopts frequency conversion speed regulation, worm gear and worm drive .

Our machine adopts frequency conversion speed regulation, worm gear and worm drive .

Intelligent Slitting Machine

It used for cutting and processing of various roll film materials.

The width can be adjusted freely and the cutting size is accurate.And the use of multi-axis multi-knife design, multiple

dimensions can be carried out at the same time cutting.Using the shaft, can be cut to a very small size.Use frequency converter or

electromagnetic speed control cutting speed.

dimensions can be carried out at the same time cutting.Using the shaft, can be cut to a very small size.Use frequency converter or

electromagnetic speed control cutting speed.

Automatic filming device

The automatic film-changing device can be used to convert a handle when one of the rolls is almost exhausted. The next roll of film can be accessed without downtime.

RECOMMEND PRODUCTS

Other Products

Why Choose Us

Our Advantages

1.The

coating system:

The whole casting aluminum precision processing, surface non-adhesive treatment, accurate, stable, high efficiency.

2.W

inding device: using air expansion shaft, convenient, simple operation, high efficiency;

3.Machine

: high quality steel welding, actual processing, overall gantry milling processing, high precision, good stability

4.Driving wheel: made of silica gel, durable and non-adhesive

5. Special-shaped pressure wheel: silica gel, different hardness, various shapes, convenient and practical!

PACKING&SHIPPING

Successful Project

FAQ

1. Q: Are you a trading company or factory?

A: We are a factory with a foreign trading department. We manufacture the plastic extruder machine by our own factory. So don't worry about the after-sell services.

A: We are a factory with a foreign trading department. We manufacture the plastic extruder machine by our own factory. So don't worry about the after-sell services.

2. Q: Where is your factory? How do I get there?

A: Factory address: Xingda Industrial Park, No. 720, North Section of Tongdu Avenue, Tongling City, Anhui Province, China. You can

take a plane to Hefei Xinqiao International Airport or Nanjing Lukou International Airport, we can arrange the pick-up. Or you can

take the high-speed rail to Tongling Station.

3. Q: In what year was your company founded?

A: Our company was founded in 2012, the founder Mr. Yuan Xu has been engaged in the plastic machinery and mold processing industry

for more than 20 years.

4. Q: What payment methods do you support?

A: We support T/T, Western Union, PayPal, and other payment methods.

5. Q: What shipping methods do you support?

A: Sea transportation, air transportation, railway transportation, and road transportation, etc. Usually, we go by sea.

6. Q: What is your packaging?

A: Our conventional packaging is: Wrap the plastic film around the machine, and then put the machine in a wooden box.

7. Q: What is your delivery time?

A: Generally speaking, the delivery time of a production line is about 50 days.

8. Q: How is your after-sales service?

A: Our equipment has an 18-month warranty and supports lifetime maintenance. We have a strong technical service team.

A: Factory address: Xingda Industrial Park, No. 720, North Section of Tongdu Avenue, Tongling City, Anhui Province, China. You can

take a plane to Hefei Xinqiao International Airport or Nanjing Lukou International Airport, we can arrange the pick-up. Or you can

take the high-speed rail to Tongling Station.

3. Q: In what year was your company founded?

A: Our company was founded in 2012, the founder Mr. Yuan Xu has been engaged in the plastic machinery and mold processing industry

for more than 20 years.

4. Q: What payment methods do you support?

A: We support T/T, Western Union, PayPal, and other payment methods.

5. Q: What shipping methods do you support?

A: Sea transportation, air transportation, railway transportation, and road transportation, etc. Usually, we go by sea.

6. Q: What is your packaging?

A: Our conventional packaging is: Wrap the plastic film around the machine, and then put the machine in a wooden box.

7. Q: What is your delivery time?

A: Generally speaking, the delivery time of a production line is about 50 days.

8. Q: How is your after-sales service?

A: Our equipment has an 18-month warranty and supports lifetime maintenance. We have a strong technical service team.

Hot Searches