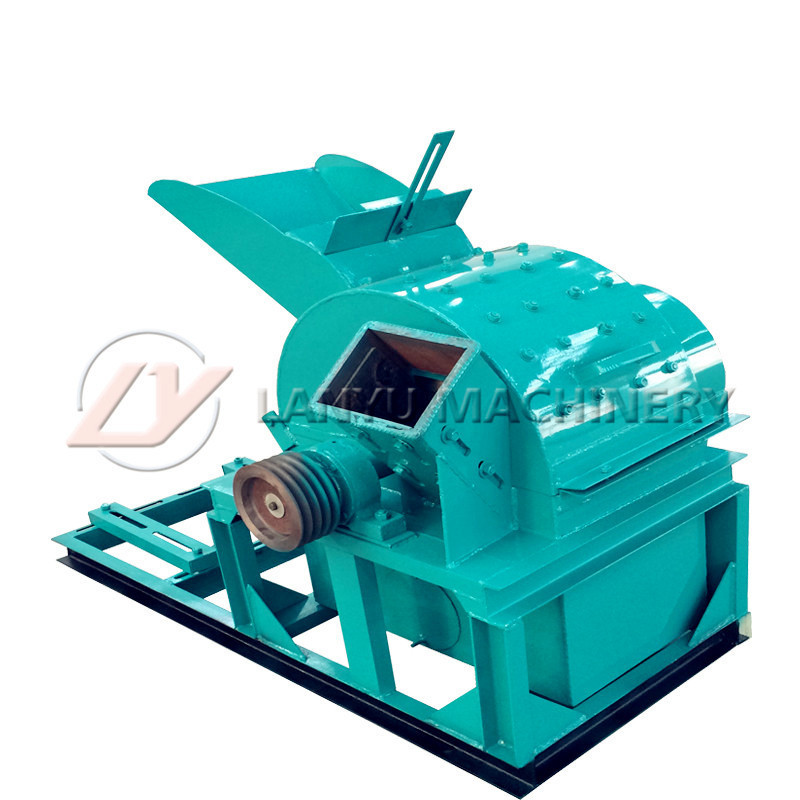

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18.5kw

-

Dimension(L*W*H):

-

1200*950*1600mm

-

Weight (KG):

-

500

-

Name:

-

Wood Crusher Machine

-

Application:

-

Wood Processing

-

Raw material:

-

Straw Grass Wood Branches

-

Product name:

-

Wood Sawdust Equipment

-

Type:

-

Multifunctional Crusher

-

Usage:

-

Crush Biomass Waste Wood

-

Capacity:

-

2-3t/h

-

Color:

-

Customer Required

-

Spare parts:

-

Hammer Blades

-

Item:

-

Hammer Mill Pulverizer

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Henan Lanyu

-

Voltage:

-

380V

-

Power:

-

18.5kw

-

Dimension(L*W*H):

-

1200*950*1600mm

-

Weight (KG):

-

500

-

Name:

-

Wood Crusher Machine

-

Application:

-

Wood Processing

-

Raw material:

-

Straw Grass Wood Branches

-

Product name:

-

Wood Sawdust Equipment

-

Type:

-

Multifunctional Crusher

-

Usage:

-

Crush Biomass Waste Wood

-

Capacity:

-

2-3t/h

-

Color:

-

Customer Required

-

Spare parts:

-

Hammer Blades

-

Item:

-

Hammer Mill Pulverizer

Product Description

Wood mill is a new type of super fine wood powder equipment developed by domestic and foreign high-tech advanced technology, the machine integrated the domestic and foreign various traditional wood mill crushing principle to be innovated, By a crushing principle of traditional wood crusher and integrated many kinds of crushing principle both at home and abroad successfully developed into a set of three kinds of crushing principle for the integration of high efficiency and energy saving timber mill,this machine with fineness analyzer, is a professional committed to the light body materials, fiber materials, brittle materials and ductile materials such as special difficult pieces of new coal pulverizing equipment. This machine adopts self-suction feeding mouth to ensure safe production, replacing the traditional mill directly feeding, carelessly into metal blocks and seriously damage the wood powder machine. The machine has fine production and high processing technology. It adopts double-layer body, which is injected with tap water to play the role of water cooling, and loaded with a new type of material to play the function of sound insulation and heat dissipation. So the machine in production and use of small noise, no vibration. Beautiful appearance, durable, high output, more than 50% efficiency than the traditional wood flour machine, is the ideal pulverizing equipment can not be replaced by any crushing equipment.

Wood crusher is suitable for crushing the following materials: Bamboo and wood powder, shells, Chinese herbal medicine, bark,leaf, wheat bran, konjac, xuan hemp, rice husk, corn cob, straws, starch, food, shrimp skin, fish meal, shells, seaweed and dehydrated vegetables, hawthorn, dried ginger, garlic, pumpkin powder, condiment, jujube, paper, circuit board, plastic products, chemical raw materials, water, condiment, feed, mica, graphite, bentonite, pearlite, Vinasse, furfural, bread, charcoal, activated carbon, cellulose, potato slag, tea, hair, soybean meal, cotton, refined cotton, leather, sheepskin, plant roots, stems, leaves,flowers, fruit, all kinds of edible hundreds of complicated characteristics, such as materials processing, chemical industry,building materials, medicine, health care, farming, food, mosquito-repellent incense, etc in the ideal grinder. (Note that woodcrusher is not suitable for crushing inflammable and explosive materials)

The wood mill crushing ratio, high production efficiency, cheap wood mill will be higher speed and stroke combined, so that the rated power and capacity of the wood mill greatly improved, realized the wood mill energy saving, high efficiency and low consumption.

Less consumption of wearing parts, low operating cost, reasonable structure, advanced crushing principle and technical parameters,reliable operation, low operating cost; All parts of the wood mill are wear-resistant protection, the maintenance cost is reduced to a minimum, the general service life can be increased by more than 30%, won the henan wood mill exclusive patent.

Alloy cutter wear-resistant sharp, reliable, advanced, improve service life unique crushing system design, greatly improve the service life of wood mill blade. The crushing chamber adopts multi-stage crushing process and crushing principle device, which is characterized by large impact force, high production efficiency and strong crushing capacity.

Wood crusher is mainly used for processing, pine, miscellaneous wood, poplar, Chinese fir, bamboo, branches, thatch, straw and other fiber materials. The material is continuously cut into small pieces by the high speed rotation of the gold steel blade(hardness up to 65 degrees), and then into the crushing chamber with a special hammer head (recyclable) hammer and friction between the materials for grinding. The other is provided with a screen (the whole circle), after crushing of the material is less than the size of the screen discharged through the air flow screen, larger than the size of the screen retained in the comminution room to continue grinding, discharged through the screen machine. Wood mill can be adjusted according to user requirements sieve size, change the discharge particle size.

Various types of crushing cavity, application flexibility, strong adaptability, wood crusher can replace the blade and screen mesh can be from the standard super thick cavity to ultrafine short head type cavity any transformation, the other the body inside the fineness analyzer, lumber mill adjusting method (after the bolt on the analyzer to loosen, move up higher fineness and lower move down the fineness, transferred to the fineness of you need, Fixed bolt before production). Therefore, the wood mill can adapt to a large range of product size requirements

two input feeding port and hammer and knife both on one machine

only hammer and only one input feeding port

wood shaving machine for animal

wood crusher for mushroom

wood chipper machine for wood

wood crusher for diesel engine

The machine is equipped with air volume regulator, adjustable air volume size, large air volume low fineness, small air volume high fineness to the ideal fineness can be continuous production. Fineness: 1-20 mm arbitrary adjustment, output and fineness according to the specific gravity of the material output and fineness are different. Host motor can be large or small, according to the fineness of the material output.

Specification

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches