- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

RTV-2 Liquid Silicone Rubber

-

Application:

-

Mold Making Materials

-

Color:

-

White

-

Appearance:

-

Liquid Two Component

-

Features:

-

High Temperature Resistant

-

Mixing ratio:

-

1:1

-

Hardness:

-

25 Shore

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HONGLIAN SILICONE

-

Model Number:

-

HF-318

-

Product name:

-

RTV-2 Liquid Silicone Rubber

-

Application:

-

Mold Making Materials

-

Color:

-

White

-

Appearance:

-

Liquid Two Component

-

Features:

-

High Temperature Resistant

-

Mixing ratio:

-

1:1

-

Hardness:

-

25 Shore

Product Description

Why could the silicone mold be reused only for a few times?

Maybe you will confuse about this question for years. Here we share you some following reasons:

* Adding too much silicone oil into silicone rubber. Silicone oil is an additive which will destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

* Adding too much catalyst into the silicone rubber when you make the molds. For the condensation cure(tin catalyst) silicone rubber. we s est you add no more than 2% of catalyst. If you 1add too much catalyst, the operation time will be too fast to operate ,which will also reduce the tension and tear strength.

* Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

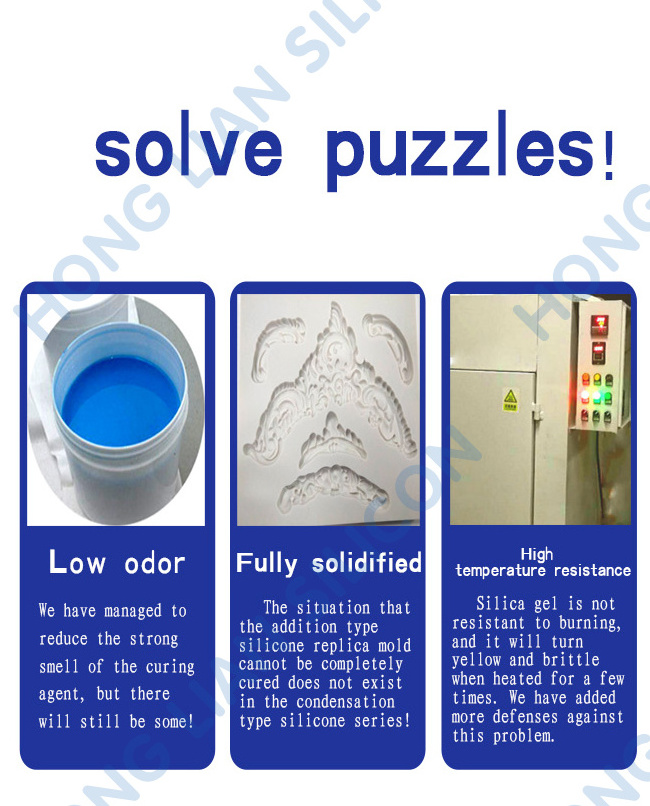

Why does the silicone mold get burnt out?

The silicone mold get burnt out because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

Our silicone rubber has add a special material which can resistant high temperature to make the resin molds. Help our customer avoid this problem.

Why does the silicone mould appear to be dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.05% water into the silicon rubber and Stir over a low speed briefly when you use it.

Why is the tear strength of silicone molds weak?

There are three reasons:

1)

In order to reduce the viscosity of silicone rubber and pursue good quality, a large amount of silicone oil can be added to the silicone rubber when making the mold. In fact, it may have the opposite effect. The addition of silicone oil can severely reduce tension and tear strength. And the silicon mold will be in a fragile and fragile state.

2)

too much catalyst may be added to the silicone rubber, we recommend that customers add catalyst no more than 5%, 2% is fine.

3)

After the silicone mold is finished, you may use it prematurely. We recommend that customers start using the mold after 24 hours. More importantly, it would be better if you could make an outer mold to protect the silicone mold.

Why does the mold silicone have poor tension?

In the process of making the mold, in order to reduce the viscosity of the silicone rubber and make the silicone rubber easy to operate, a large amount of silicone oil is added to the silicone rubber, which will make the silicone rubber very soft, resulting in poor tensile strength and reduced tear strength. The phenomenon of poor tensile force, resulting in the phenomenon that the mold is not durable, the service life is short, and the number of mold overturns is small.

What else wonderful usages of mold silicone do you know?

Mold silicone rubber is mainly used in toy and gift industry, craft gift industry, furniture decoration industry, character reproduction, building decoration and decoration industry, resin handicraft industry, unsaturated resin handicraft industry, candle craft, plastic toy industry, gift stationery industry, gypsum Craft gift industry, mold manufacturing industry, glass industrial products, simulation animal and plant sculpture, Buddha carving crafts and other industries product replication and mold making.

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Guangdong

|

|

Brand Name

|

HONGLIAN SILICONE

|

|

Model Number

|

HF-318

|

|

Product name

|

RTV-2 Liquid Silicone Rubber

|

|

Application

|

Mold Making Materials

|

|

Color

|

White

|

|

Appearance

|

Liquid Two Component

|

|

Features

|

High Temperature Resistant

|

|

Mixing ratio

|

1:1

|

|

Hardness

|

25 Shore

|

Note: all of the above data all can customized by customers requirements.

FAQ

一、Who are we?

We are based in Guangdong, China, start from 2016,sell to Eastern Europe(27.00%),Western Europe(25.00%),Mid East(20.00%),Eastern Asia(15.00%),North America(13.00%).There are total about 11-50 people in our office.

二、How can we guarantee quality?

As real factory we have a professional team support you.

Always a pre-production sample before mass production;

Always final Inspection before shipment;

with quality certifications

三、What can I buy from you?

You can get it from us,silicone oil、RTV-2 mold silicone、Human silica gel、Food grade silicone、Textile silica gel、Pad printing silicone、color paste

四、 Why should you buy from us not from other suppliers?

1. More than 20 years' experience in R& D of silicone rubbers.

2. With production capacity of 100 tons per month.

3. Verified by SGS, MSDS, ROHS, certificates.

4. 5 patents in manufacturing to ensure quality & efficiency.

五、 What services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Language Spoken:English

Sufficient inventory, fast delivery

Real factory with R&D,quality system ,production department,and technical support.

Contact us

Sandy/ CC

Sales Manager

Tel./Whatsapp:+86 13662816580

E-mail:iamsandycc@outlook.com

Add:Chang 'an city, Dongguan City China

Hot Searches