- Product Details

- {{item.text}}

Quick Details

-

Color:

-

White/Ivory

-

Hardness:

-

1100~1600 Kg/mm2

-

Max Working Temperature:

-

1100~1650℃

-

Size:

-

Customer's Drawing

-

Property:

-

High Temperature Resisitance

-

Advantage:

-

12 Years Industrial Ceramics Experience

-

Package:

-

Carton Box or as your detailed requirements

-

Shape:

-

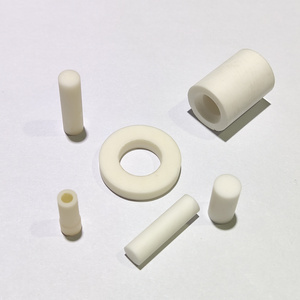

Rod/Shaft/block/Plate/Needle/Tube/Parts

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Guangdong, China

-

Density:

-

3.65 - 3.85 G/cm3

-

Color:

-

White/Ivory

-

Hardness:

-

1100~1600 Kg/mm2

-

Max Working Temperature:

-

1100~1650℃

-

Size:

-

Customer's Drawing

-

Property:

-

High Temperature Resisitance

-

Advantage:

-

12 Years Industrial Ceramics Experience

-

Package:

-

Carton Box or as your detailed requirements

-

Shape:

-

Rod/Shaft/block/Plate/Needle/Tube/Parts

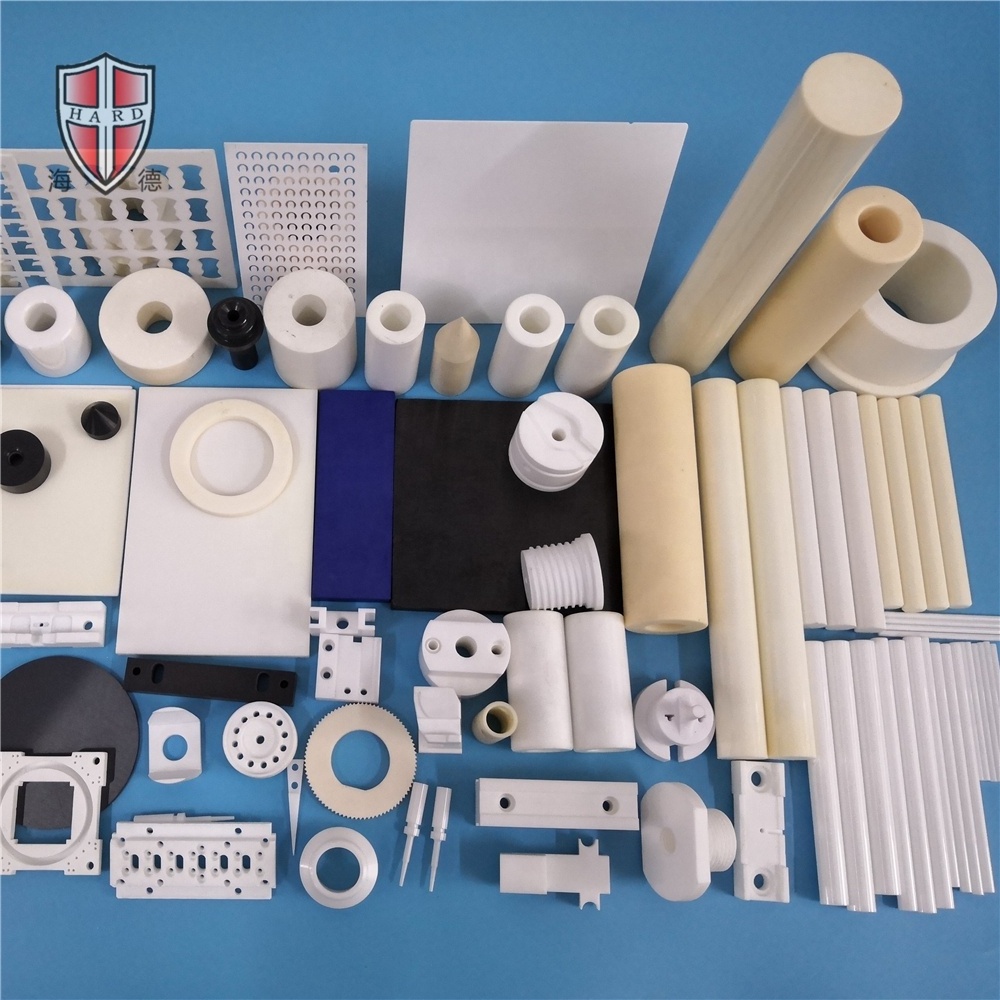

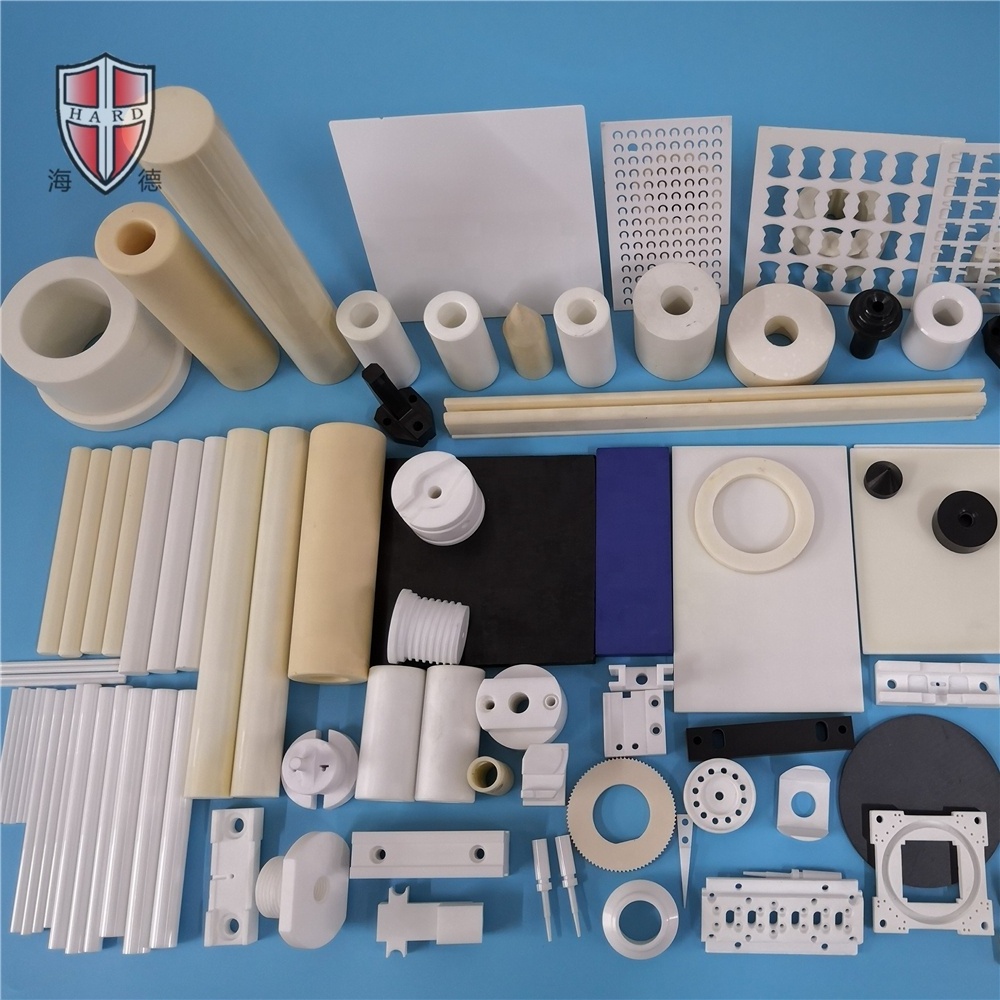

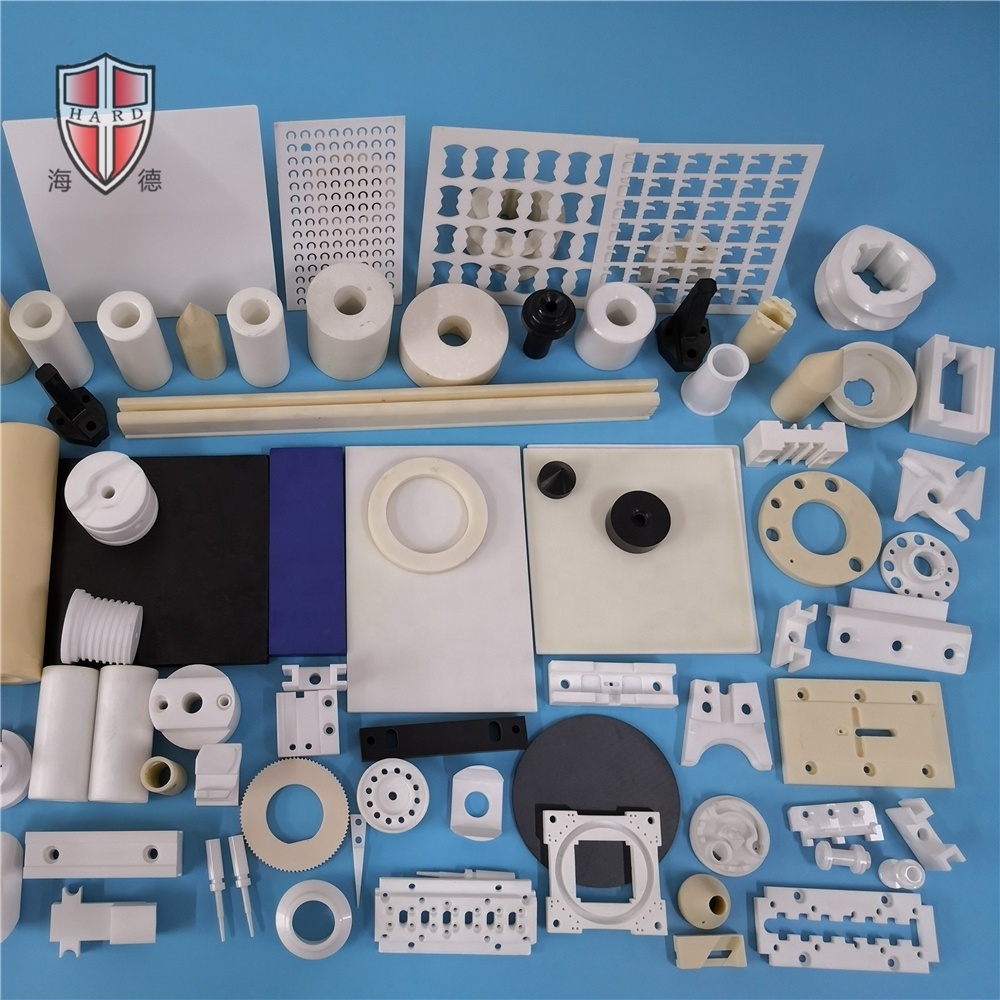

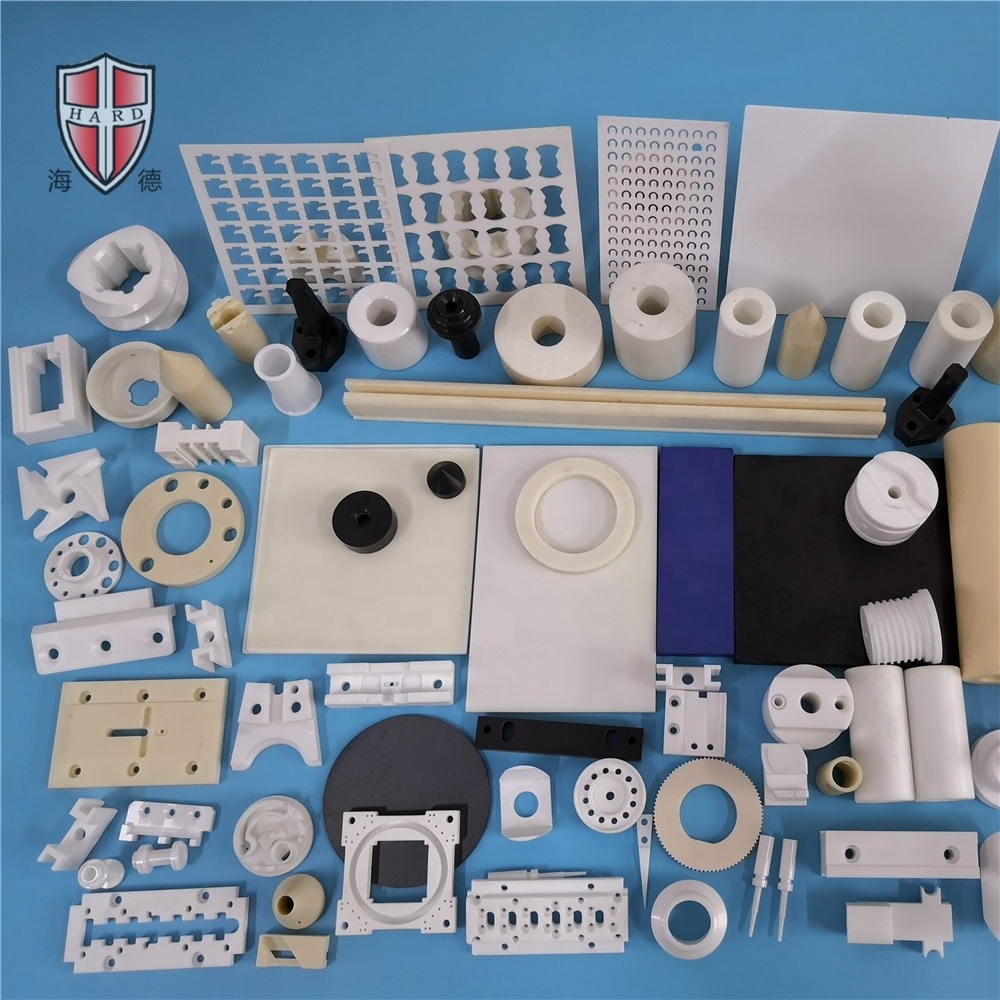

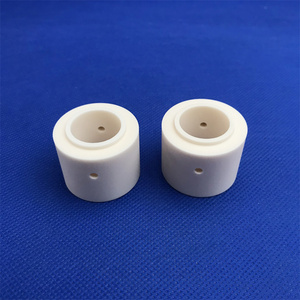

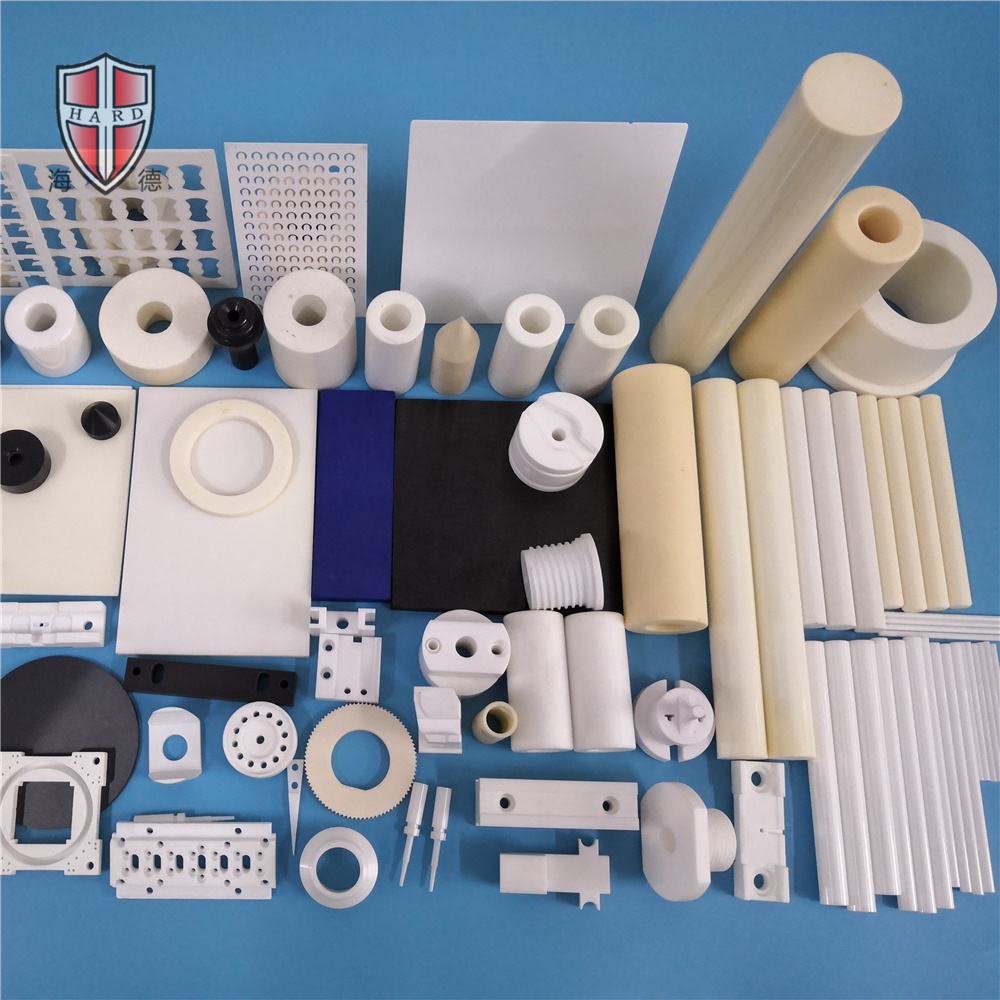

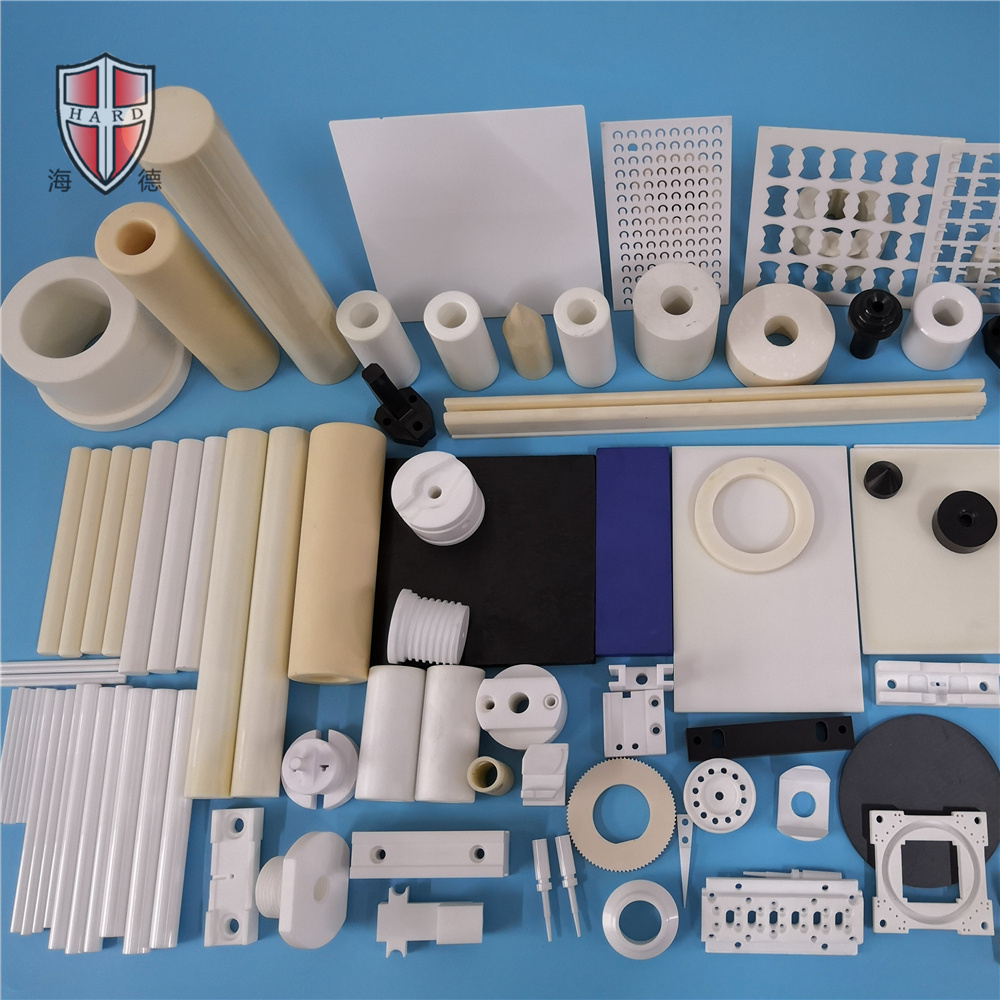

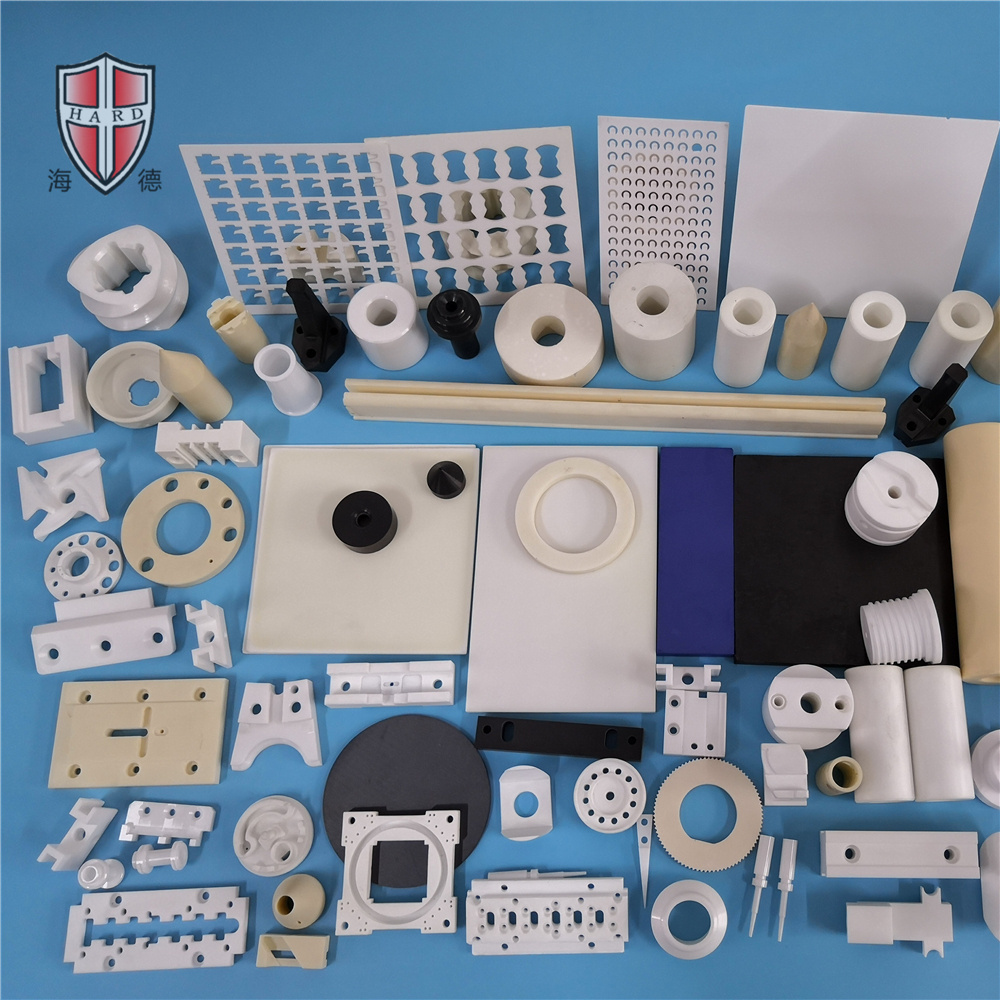

Insulators Ceramic Ring/Tube/Rod/Plate thread part Supplier

Product Description

Advanced ceramic application propect are very widely.Such as be used in aerospace,aviation,military industry,nuclear power,machinery,texile,chemical,electronic,food,medical,ect.

| Alumina Ceramic Properties | 96% Alumina Ceramic | 99% Alumina Ceramic | |

| Item | Unit | Typical Values | |

| Physical Properties | |||

| Color | White | Ivory | |

| Density | g/cm3 | 3.7 | 3.85 |

| Alumina Content | % | 96% | 99% |

| Gas permeability | 0 | 0 | |

| Water Absorption | 0 | 0 | |

| Mechanical Properties | |||

| MONS' Hardness | Grade | 9 | 9 |

| Rockwell Hardness | HRA | 80 | 82 |

| Vickers Hardness (Hv50) | Gpa(Kg/mm²) | 15.7(1600) | 15.7(1600) |

| Flexural Strength(20°C) | Mpa | 300 | 330 |

| Compressive Strength(20°C) | Mpa | 2000 | 2000 |

| Modulus of Elasticity | Gpa | 275 | |

| Poisson's Ratio (20°C) | 0.22-0.23 | ||

| Fracture Toughness(20°C) | MPam1/2 | 3.5 | 4 |

| Thermal Properties | |||

| Thermal Conductivity(20°C-400°C) | W(m.K) | 25 | 27.5 |

| Thermal Expansion | 10-6/°C | 6.5-7.5 | 7.6 |

| Maximum Use Temperature | °C | 1600 | 1650 |

| Electronic Properties | |||

| Dielectric | KV/mm | >12 | >10 |

| Dielectric Constant | Er | 9-10 | 9.1 |

| Dielectric Loss Angle(1MHz) | 0.0002 | 0.0002-0.0003 | |

Product Features

Compared with metal materials, the advanced ceramic with high hardness, high strength, high temperature, wear resistance, corrosion resistance, acid and alkali resistance, oxidation resistance, insulation, nonmagnetic, good chemical stability and other excellent performances.

Product Show

Our Service

Our Company

HARD develops fine ceramic products which are widely used in machinery, semiconductor, aerospace, petroleum, chemical, electronics, medical, fluid control, food and other industries. The superior electrical characteristics of fine ceramics are utilized in a variety of circuit boards and electronic parts. Their wear and corrosion resistance is beneficial in pumps nozzles and valve parts, and their high heat and thermal shock resistance is useful in ceramic engine parts.

We have a full service include ceramic forming,mold design and development,precision machining and precision detection technology, and our technician have many years of experience in ceramic processing. We can provide a full set of ceramic solutions for customers, and can make different kinds of ceramic products according to customer's special request.

Packing & Delivery

Main Products

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: