- Product Details

- {{item.text}}

Quick Details

-

Pressure:

-

0.1-0.2

-

Weight:

-

20

-

Power:

-

800W, 1200W, 2200W, 800W, 1200W, 2200W

-

Dimension(L*W*H):

-

30*30*20cm

-

Product Name:

-

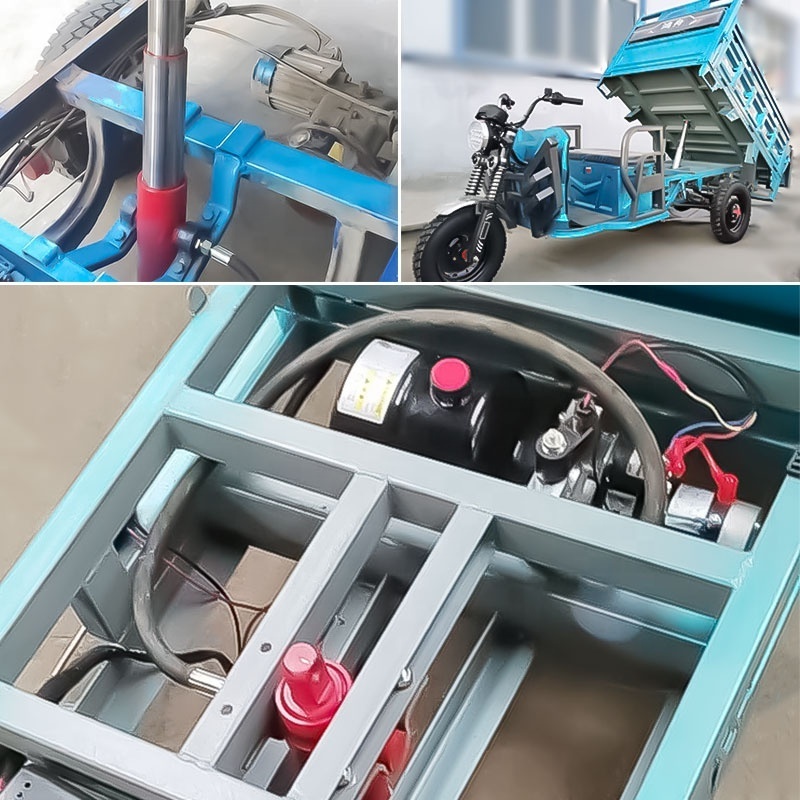

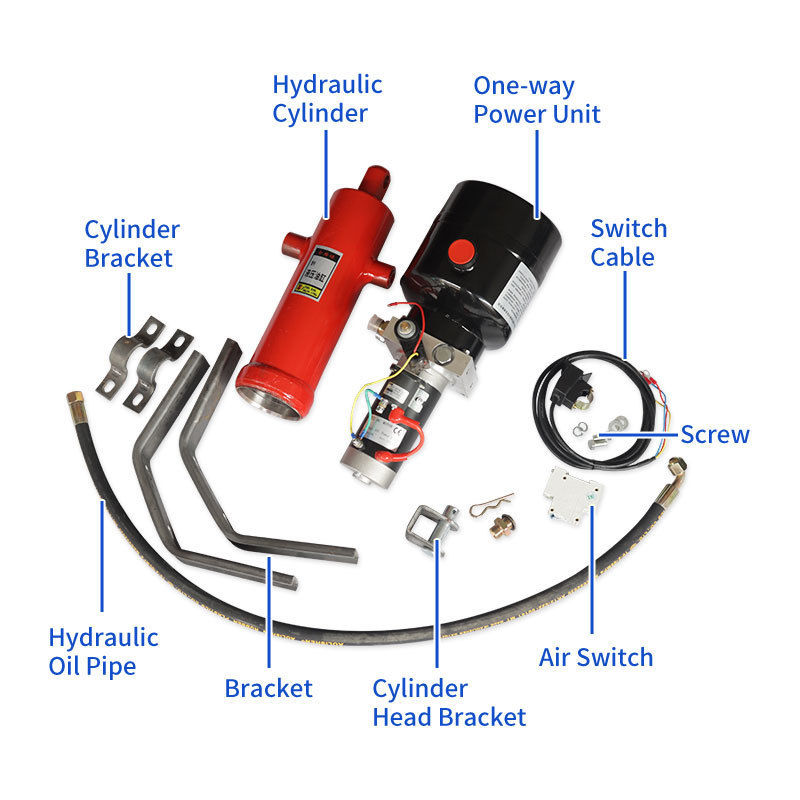

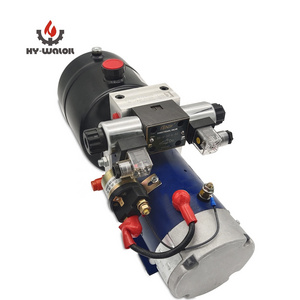

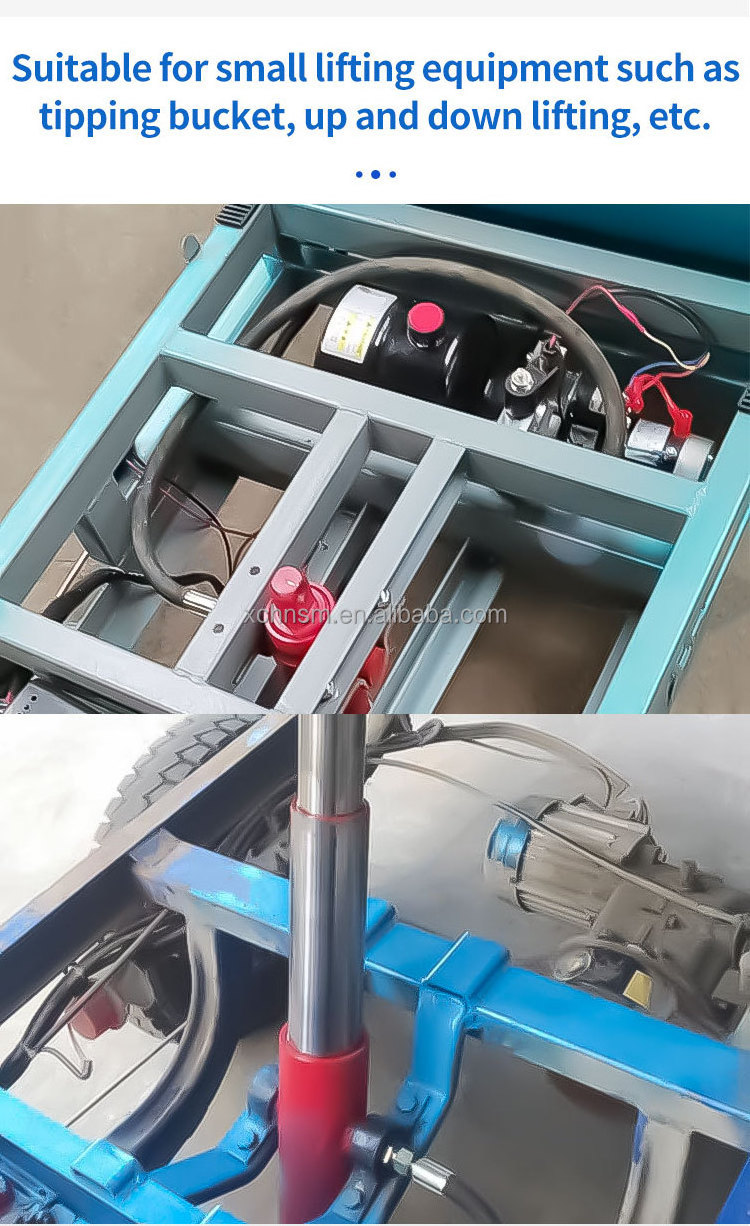

12V 24V Hydraulic dump power unit kit

-

Country of Origin:

-

China

-

Application:

-

electric dump truck pallet stackers

-

Keywords:

-

Hydraulic Cylinders Pump Power Unit

-

Voltage:

-

12V, 24V

-

Electric current:

-

18A

-

Hydraulic cylinder capacity:

-

4L

-

Total stroke of hydraulic cylinder:

-

450-900mm

Quick Details

-

Warranty:

-

6 Months

-

Brand Name:

-

hengnayuan

-

Place of Origin:

-

Henan, China

-

Pressure:

-

0.1-0.2

-

Weight:

-

20

-

Power:

-

800W, 1200W, 2200W, 800W, 1200W, 2200W

-

Dimension(L*W*H):

-

30*30*20cm

-

Product Name:

-

12V 24V Hydraulic dump power unit kit

-

Country of Origin:

-

China

-

Application:

-

electric dump truck pallet stackers

-

Keywords:

-

Hydraulic Cylinders Pump Power Unit

-

Voltage:

-

12V, 24V

-

Electric current:

-

18A

-

Hydraulic cylinder capacity:

-

4L

-

Total stroke of hydraulic cylinder:

-

450-900mm

Recommend Products

Specification

|

Product name

|

12V 24V Hydraulic dump power unit kit

|

|

Advantage

|

Six months warranty, quiet and efficient.

|

|

Product information

|

1 ton 58*450mm type: (2 oil cylinders) 12V 800W power unit kit

1.5 ton 58*450mm type: (2 oil cylinders) 12V 1200W power unit kit

2 ton 71*550mm type: (2 oil cylinders) 24V 1200W power unit kit

3 ton 86*750mm type: (3 oil cylinders) 24V 2200W power unit kit

|

|

Precautions

|

Hydraulic oil is not included in the unit kit, 4 liters of hydraulic oil is required for installation.

When the oil cylinder falls, the carriage needs to have a certain self-weight, and the 2-section 50CM model requires the carriage

to weigh more than 50KG. If the self-weight is insufficient, external pressure is required. |

|

Warranty Policy

|

Motors and relays are guaranteed for half a year, and if there is a non-artificial quality problem within half a year, they will be replaced unconditionally.

|

Product Description

Precautions for the use of hydraulic units

1. The hydraulic power unit is installed correctly and the power is connected correctly. Pay attention to whether the voltage of the motor and solenoid valve is consistent with the power supply. Filter the hydraulic oil when refueling. The original parts such as oil cylinder and pipeline must be kept clean.

2、The working pressure of the hydraulic power unit has been adjusted before leaving the factory, please do not adjust it arbitrarily.

3. The power unit adopts the S3 working system and cannot run continuously. It starts at 30 seconds and stops at 270 seconds.

4. Hydraulic oil is HM32 in winter, HM46 in spring and autumn, and HM68 in summer. When the system is used for 100 hours, the hydraulic oil should be replaced. Change the hydraulic oil every 1000 hours thereafter.

|

Fault Method of exclusion

|

|

|

|

1. Motor does not turn

|

Check whether the connection line is correct

|

|

|

2. The motor can start, but the cylinder does not work

|

The hydraulic oil in the fuel tank is too low, fill it to the specified scale

|

|

|

|

Please use the recommended hydraulic oil according to the season and temperature

|

|

|

|

The oil suction filter is clogged, please clean and replace the filter

|

|

|

|

Check electrical wiring or clean solenoid valve

|

|

|

3. When the load is unloaded, the oil level of the cylinder does not drop or drops too slowly

|

The solenoid valve is not energized, please check the electrical wiring

|

|

|

|

The solenoid valve input voltage is incorrect, please check the voltage

|

|

|

|

The solenoid valve filter is blocked, please remove it to clean or replace the filter

|

|

|

4. After the switch is turned off, the motor can still work intermittently

|

The wire is connected incorrectly, please check the wiring

|

|

|

|

Start switch failure, check and replace the start switch after power failure

|

|

|

5. Excessive noise during operation

|

The hydraulic system contains air, and the air is removed by repeated operation several times in a row

|

|

|

|

Please do not work long hours under extreme pressure

|

|

Packing & Delivery

Hot Searches