- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.9*1.1*1.2m

-

Warranty:

-

12 Months

-

Name:

-

briquette making machine for sale in south africa

-

Color:

-

Client's Required

-

Inler size:

-

less than 5mm

-

Appearance:

-

Square, hexagonal,round

-

Moisture of material:

-

less than 25%

-

Final shape:

-

Solid or hollow

-

Operation:

-

Easy Operation

-

Diameter of final production:

-

10-100mm

-

Application:

-

Barbecue (BBQ)

-

Raw material:

-

Charcoal Powder

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

1-6T/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CANMAX

-

Dimension(L*W*H):

-

1.9*1.1*1.2m

-

Warranty:

-

12 Months

-

Name:

-

briquette making machine for sale in south africa

-

Color:

-

Client's Required

-

Inler size:

-

less than 5mm

-

Appearance:

-

Square, hexagonal,round

-

Moisture of material:

-

less than 25%

-

Final shape:

-

Solid or hollow

-

Operation:

-

Easy Operation

-

Diameter of final production:

-

10-100mm

-

Application:

-

Barbecue (BBQ)

-

Raw material:

-

Charcoal Powder

-

Certification:

-

CE ISO

CANMAX best price for charcoal briquettes machine

Coal rod machine introduction:

Coal rod machine is the briquette machinery, which using the principle of screw extrusion to compress the coal powder into a predeter mined shape with a certain intensity. after the coal powder poured into machine chamber,it bears tremendous pressure. With the help of all kinds of shaped molds, it will be shaped into certain shapes.

Now, our factory has developed and researched double-head and four-head coal extruder. It not only improve production capacity largely, but also give the buyers more choices. This kind machine not only can accept coal powder, but also charcoal powder coconut shell powder and so on.

Features

*1

Coal/charcoal briquette making machine/best price for charcoal briquettes machine use hardened reducer,small size,high load carrying capacity.

*2

Thick internal impeller blade design,impeller and liner using wear-resistant cylinder body made of cast

materials, life expectancy increased 4-5 times than ordinary materials.

*3

Coal/charcoal briquette making machine/best price for charcoal briquettes machine head can be replaced by a wear-resistant alloy steel,also easy to replace.

*4

head and cylinder use splicing forms so it can be opened when the overhaul,replacement of internal

impeller and cylinder liner is very convenient.

Mould

Finished Product:

Working Principle:

*1 The motor transmits power to transmission through the V-belt.

*2 At the same time, the transmission output shaft transmits power to propeller through the floating coupling.

*3 The thruster of propeller push the materials forward through forming to produce the high- pressure sticks.

Technical Parameters:

| Model | Power | Capacity(Ton/hr) | Reducer | Weight(Ton) | Packing size(M) |

| HYQ-140 | 7.5/11 | 0.4-0.5 | ZQ350 | 1 | 1.9*1.1*1.2 |

| HYQ-180 | 18.5/22 | 1-1.2 | ZQ400 | 1.6 | 2.1*1.5*1.2 |

| HYQ-300 | 37 | 1.8-2.2 | ZQ650 | 2.5 | 3.2*2.3*1.2 |

| HYQ-450 | 45 | 3.5-4 | ZQ850 | 5 | 3.6*2.6*1.6 |

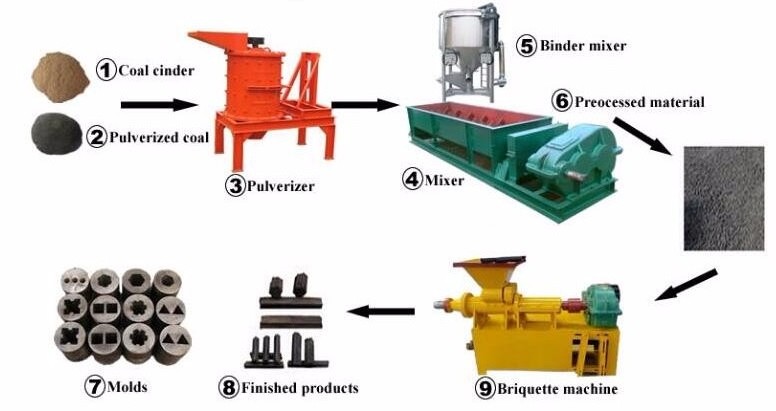

Working Flow:

*1 Binder mixer: It is using for dissolving and thicking binder.

*2 Crusher and mixer: It is a machine with the function of crushing and mixing together, crushing the raw material below 5mm, and mixing them uniformly. The moisture need controlled between 25%-30%.

*3 Coal briquette machine: It presses coal powder, charcoal powder, or other powders.

*4 Dryer: We have vertical dryer, box dryer and mesh belt dryer. I will suggest suitable dryer according to your raw machine, shape and size.

related products:

In addition to the coal rod machine, we also have a tablet press, a ball press, and a briquetting machine for you to choose.

1.Charcoal/coal ball press machine

Working video: https://youtu.be/Pb0s0N2Aut0

2.shisha tablet pressing machine

Working Video: https://youtu.be/tXhuNaCb9WI

3.Honeycomb coal/charcoal making machine

Working video: https://youtu.be/WwFOSqqBvzI

Packing:

Related Questions for Customer:

(After we know those questions, we could give you the best quotation. So, Please tell me those questions first.)

*1 what's Raw material ?

*2 The moisture and size of raw material ?

*3 Capacity you need ?

*4 The shape and size of the final product you prefer?

Apart from the charcoal briquettes extruder, other related machine such as feeder, grinder, crusher, conveyor and dryer are also available in our factory, it means we can offer a whole product line. In addition, we can help you with the installation.

Raw material-----Crushing -----Mixing-----Feeding-----Briquetting----drying--Final briquette

Pre-sale:

*1

Suggest to client suitable models of as customer need.

*2 Introduce machine's structure and features in detail, explain the price component;

*3 answer client concerned questions .

After-sale:

*1 . Start production as soon as receiving down payment.

*2

Send photos of machine in manufacturing and finished photos to client, for your better

learn about the machine's condition.

*3

Delivery machine in time, taking photos during loading, so you can "remote monitoring"

your goods.

*4 Documents and certificate available in time.

*5 Manual documents available. Engineer can be sent to client site for installation instruction.

Certificate

FAQ:

*1

Payment accepted: After confirming all the details with our sales, we will make contract for you to make deposit first and the balance need to be cleared against shipping. Generally we accept most of the payment methods like TT, L/C, PayPal, West union, Moneygram.

*2

Lead time: 7 working days against your deposit.

*3

What about the quality: We use the best NATIONAL certified steel and high manganese steel for the blades to make our products 1.5 times than other factories.

*4

Warranty: 12 months warranty and life time service. (We have engineer available to serve overseas)

*5

Certificate: ISO, CE, CCC

*6

How can I get to your company: We are located in Gongyi City. You can fly to XINZHENG INTERNATIONAL AIRPORT and we will pick you up there.

About CANMAX:

We are a professional manufacturer of various machines for 14 years. Our main products includes Block making machine, concrete mixer, dry mortar mixer, charcoal machine, Coal briquette machine, Wood Crusher, Oil press machine, Biomass briquette machine, food machinery, etc.

With 6 years exporting experience, we are now the leading supplier in middle China now, our products has been exported to more than 55 countries in the world. Clients profits go first is our principle. We have good faith in working with you and we are sure CANMAX team is one of your best Choices in China.

Contact Us:

|

Nina

|