- Product Details

- {{item.text}}

Quick Details

-

Material:

-

PEEK

-

Package:

-

Wooden Box

-

Feature:

-

withstand high temperature

-

OEM NO:

-

yes

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

yuanju

-

Product name:

-

compressor valve

-

Material:

-

PEEK

-

Package:

-

Wooden Box

-

Feature:

-

withstand high temperature

-

OEM NO:

-

yes

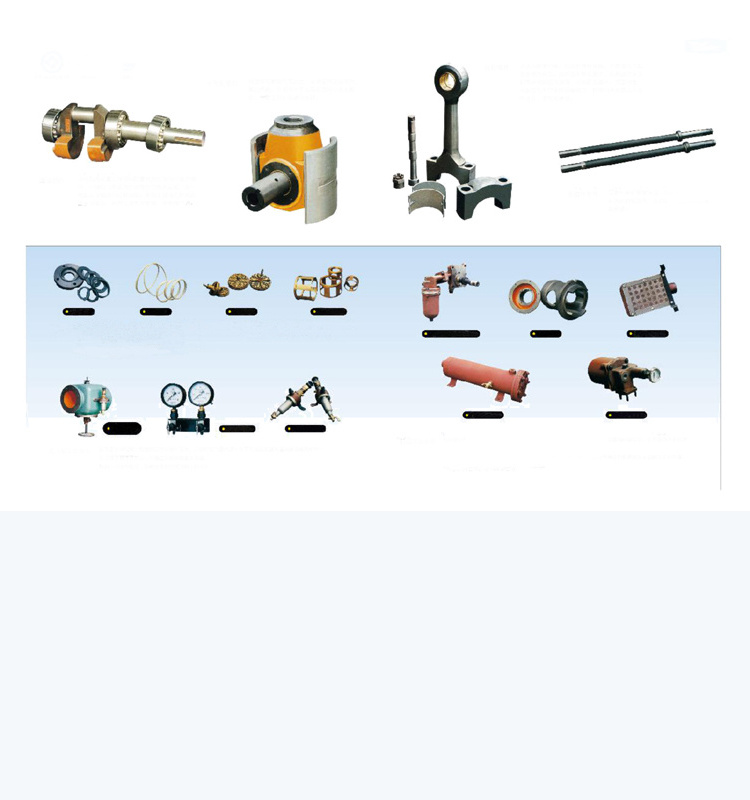

plate valve/peek valve/ring valve/poppet valve

Yua

nju

is working hard to be the most reliable source of carrying a complete line of compressor valve

As the heart and main replacement part of compressor,valve is crucial for compressor efficiency and withstand

assemblies

for air compressor and process gas compressor , as well as the source of OEM service of any other

brand

compres

sor.

We adopt state-of -the-art process to produce compressor valves with the high quality stress

free steel and

the most

durable thermoplastic or mental internals. There are many equipment include cnc

machines,

lathers, grinding

machines

and other traditional equipment involved in the production process.

Each valve design

is proven with highly

sophisticated computer software.Our expert engineer team with many

years experience on

invaluable oem knowledge,

focus on the goal to maximize flow area, optimize performance

and running time,as a

result, low pressure drop helps

to reduce energy consumption.

As the heart and main replacement part of compressor,valve is crucial for compressor efficiency and withstand

the most road load, also can limit the compressor reliability and availability .Generally being an automatic valve,

its opening and closing are realized by the pressure difference and spring force on both sides of the valve plate.

Yuanju valve can bear various pressure ranging from vacuum to 10000 psig,perform optimally even at the max

high speed of 1800 rpm. Yuanju provides customers with a comprehensive range of ring valve, plate valve,

poppet valve,reed valve to match the specific compressor operating conditions,as well as the plates,spring,

spring plate,discs,damper plate,leaf poppets,valve springs,buttons,seat,valve guard for any other brand

valve.

Advantages

-- Availability and Reliability

Especially valve plate and springs are fabricated from carefully Selected steel that exhibit high resistance to

-- Availability and Reliability

Especially valve plate and springs are fabricated from carefully Selected steel that exhibit high resistance to

wear and corrosion.Durable materials with rugged design and 100% quality ensure the longest possible run

times in the most hostile operating environments.

-

-

Stress free mental plate and discs with special heart treatment.

- - Advanced computerized softer design

--- Engineer team with oem experience on compressor and parts

--- Engineer team with oem experience on compressor and parts

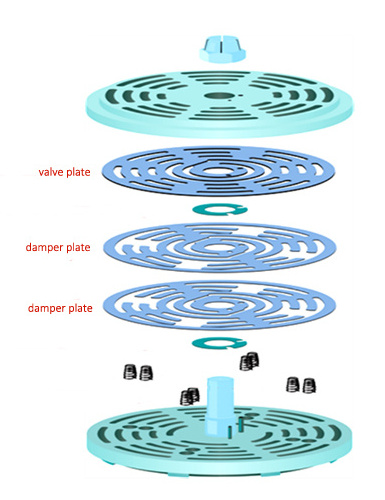

Plate valve

.

Ideal for medium and high-pressure oil free compressors

.

O

perating at high speed and wide range of capacity

.

Valve plate and damper plate in high quality heat treated steel can be customized according to request also

.

G

enerally valve seat and valve guard in 2Cr13 or HT450, valve Plate and disc in 3cr13

.

Finished double damper plate are available for reducing the strong impact

.

Customized spring for specific application to optimize opening and closing times

.

E

xcellent surface finishing ensure the low leakage

.

P

ressure fork valve mounted with unloaders for greater operating flexibility

.

S

imple structure and easy maintenance

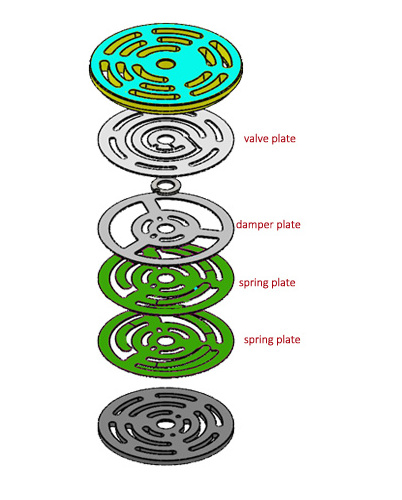

Two types of metallic valve is shown as below :

spring type and spring plate type

Non-Metallic plate valve :

. Ideal application ranging from inert gas to the corrosive gases

. Higher ductility results in better impact properties

. More resistance to liquid impact,impurities and oil adhesion

. Ideal application ranging from inert gas to the corrosive gases

. Higher ductility results in better impact properties

. More resistance to liquid impact,impurities and oil adhesion

.

W

ide flow design prevent clogging

. R educe the serious damage to the other components

. Easily maintained and reconditioned

. Greatly reduced secondary damage to other cylinder components in case of failure

. N ot suitable for oxygen compressor and ultrahigh temperature compression

. T hermoplastic material valve components from Peek,PPS,nylon,filled PTFE

. E xcellent chemical resistance, high temperature tolerances and low density

. R educe the serious damage to the other components

. Easily maintained and reconditioned

. Greatly reduced secondary damage to other cylinder components in case of failure

. N ot suitable for oxygen compressor and ultrahigh temperature compression

. T hermoplastic material valve components from Peek,PPS,nylon,filled PTFE

. E xcellent chemical resistance, high temperature tolerances and low density

non-metallic plate result in long

lifetime than metallic valve as shown :

Specification

|

Compressor speed

|

max 1800rpm

|

|

Outlet pressure

|

max 300bar /2900psig

|

|

Temperature range

|

max 160℃/

|

|

Diameter dimension

|

min 40mm, max 383 mm

|

Ring valve

Concentric rings and steel valve seat, valve guard are used to fabricate the ring valve ,applied for various

speed and high pressure ratio application .

---Easy to assemble and disassemble.

---Simple structure and less stress concentration leading to good fatigue resistance.

---Ideal for lubricated oil compressor in a wide range capacities.

---Special treatment for steel internals.

---Higher suitability for contaminated environment.

Poppet valve:

As the non-mentalic plate valve,Poppet Valve is suitable for in demanding applications with gases containing

oil and

particles as well for clean gases like natural,hydrogen or technical gases. The large lifts and wide flow

results in less pressure drop increased efficiency as well as reduce the risk of clogging. Furthermore, the design

allows for easy

maintenance and offers

significant advantages as follows:

-Ideal for lubricated or oil free compressor.

-low risk of the loss of total valve performance:

-A single poppet element fails won’t effect other poppets

-Peek and nylon material for poppet sealing parts.

-Available for application with gases containing oil and particle,debris or liquid

-Easy maintaining and reconditioning on the spot

-Optimized flow area lead to the less pressure drop

Safety

--Lower noise emissions and reduced vibrations achievable

---Less sensitive to variable operating conditions

---Minimized risk of secondary damage to the compressor parts in case of a failure

--The metallic springs are protected from gas stream by the non-metallic poppet body

Hot Searches