- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

800mm*600mm*2100mm

-

Weight:

-

1200 kg

-

Feeding width:

-

300mm

-

Marketing Type:

-

New Product

-

Product name:

-

3D Gusset plate roll forming machine

-

Effective area:

-

750mm*500mm

-

Opening height:

-

450mm

-

Motor power:

-

7.5KW

-

Nominal force:

-

1000KN (100 tons)

-

Liquid working force:

-

25Mpab

-

Fuel tank volume:

-

160L

-

Fuel tank type:

-

air-cooled (optional)

-

Sheet forming size:

-

300mm*300mm

-

Mold assembly size:

-

480mm*480mm (mold is adjustable)

Quick Details

-

Type:

-

Gusset plate roll forming machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

8-10 Pcs/min (normal) 15-17 pcs/min (fast)

-

Rolling thinckness:

-

0.2-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hokang

-

Voltage:

-

380V / 220V or as required

-

Dimension(L*W*H):

-

800mm*600mm*2100mm

-

Weight:

-

1200 kg

-

Feeding width:

-

300mm

-

Marketing Type:

-

New Product

-

Product name:

-

3D Gusset plate roll forming machine

-

Effective area:

-

750mm*500mm

-

Opening height:

-

450mm

-

Motor power:

-

7.5KW

-

Nominal force:

-

1000KN (100 tons)

-

Liquid working force:

-

25Mpab

-

Fuel tank volume:

-

160L

-

Fuel tank type:

-

air-cooled (optional)

-

Sheet forming size:

-

300mm*300mm

-

Mold assembly size:

-

480mm*480mm (mold is adjustable)

Products Overview

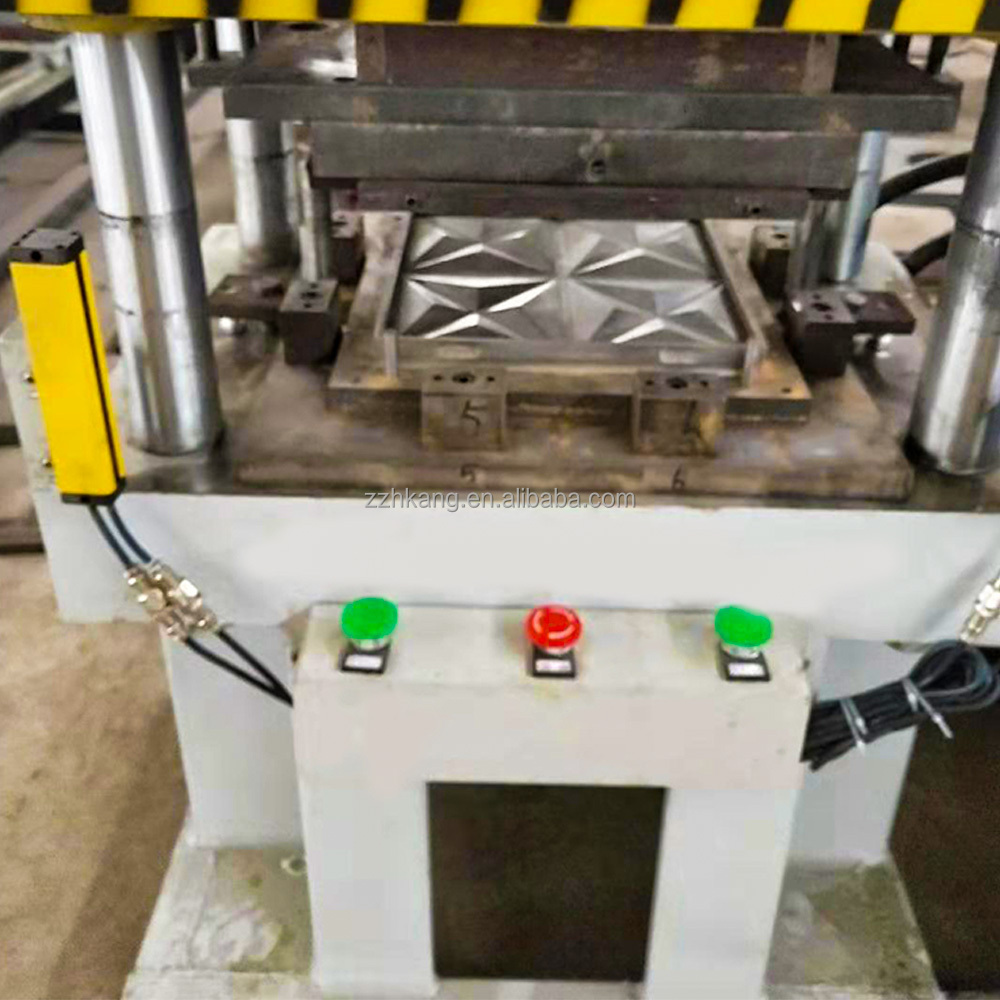

3D Wall Panel Roll Forming Machine Advertising Gusset Plate Making Machine

The 3d wall panel machine is a hydraulic pressing machine. It has the characteristics of small footprint, simple operation and good performance.It is suitable for all kinds of tensible materials, such as aluminum tensile plate, galvanized aluminum board.The R angle is small and uniform, the surface is flat, the splicing is neat, and the thick and thin materials do not need to be adjusted. We are committed to the development and production of 3D wall panel machines, aiming to save costs for 3d wall panel manufacturers and improve the quality and efficiency of products.

Features of equipment

1. Simple circuit, reliable use, easy maintenance

2. Manual feeding, one step in place automatically cut corners, fold four sides, double buckle and trademark.

3. Can customize the mold, various styles.

4. Simple operation, high efficiency.

1. Simple circuit, reliable use, easy maintenance

2. Manual feeding, one step in place automatically cut corners, fold four sides, double buckle and trademark.

3. Can customize the mold, various styles.

4. Simple operation, high efficiency.

Finished product

Rolled material thickness: 0.24-0.6mm

Finished

specifications: According to the customer's drawings, the unfolded width and size are designed according to the customer's determined size and the pattern is optional.

Specification

|

3D wall panel making machine hydraulic press advertising gusset plate roll forming machine

|

|

|

|

Suitable material

|

Color steel sheet , galvanized steel sheet,aluminum sheet

|

|

|

Installation Dimension (L*W*H)

|

800X600X2100mm

|

|

|

Thickness of material

|

0.3mm~0.8mm,customize available

|

|

|

Controlling system

|

PLC

|

|

|

Effective area of worktable

|

750mm*500mm

|

|

|

Opening height

|

450mm(distance from slider to worktable)

|

|

|

Liquid working force

|

25Mpa

|

|

|

Effective stroke of master cylinder

|

260mm

|

|

1. Effective area of workbench:

750mm*500mm

2. Main machine appearance area:

800mm*600mm*2100mm

3. Opening height:

450mm (distance from slider to workbench, four-column diameter 65mm, tempered chrome plating, composite copper sleeve sliding fit)

4. Motor power:

7.5KW (pure copper core national standard Weiyuan motor) Motor type: ordinary/noise reduction (optional)

5. Nominal force:

1000KN (100 tons)

6. Liquid working force:

25Mpab

7. Master cylinder effective stroke:

260mm

8 Effective stroke of lower jack cylinder:

120mm

9.

Control mode:

push down with both hands, manual and fully automatic functions, light curtain protection

10. Electronic control form:

electric, can be inching, and can be controlled using an electric contact pressure gauge.

11.

Electromagnetic cartridge integrated reversing valve, pressure adjustable

12. Work efficiency:

8-10 pieces/min (normal) 15-17 pieces/min (fast)

13. Fuel tank volume:

160L (fill with 46# hydraulic oil) Fuel tank type: air-cooled (optional)

14. Sheet forming size:

300mm*300mm

Mold assembly size: 480mm*480mm (mold is adjustable)

Pattern mold size: 299mm /287mm (material A3 45# GR12 optional)

15. Forming mold:

pattern optional (6 sets randomly delivered)

Product Details

3D wall panel making machine hydraulic press advertising gusset plate roll forming machine

Widely used in door signboards, floor wall (curtain wall).With its rich and beautiful color, corrosion resistance, anti - typhoon, not easy to deformation.Installation is convenient, low cost advantages, high cost performance, become the leader in decorative materials, is recognized by more and more customers.

Why Choose Us

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, the Philippines, Malaysia, India, and other countries

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Our technical personnel arrive at the customer's site in Malaysia for technical guidance and training,If a customer encounters technical problems that are difficult to solve during use, we usually send professional and technical personnel to foreign customer sites for guidance and training. Therefore, if you want to do business in cold bending forming equipment, please feel free to contact our customer service personnel at any time.

Hot Searches