- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

DRC

-

Model Number:

-

ZK2102-500

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

3600mm/3200mm/1800mm

-

Power (kW):

-

19kW

-

Weight (KG):

-

6000 KG

-

CNC Gun Drilling Machine:

-

2 Spindle Gun Drilling Deep Hole Drilling Machine

-

Drill hole diameter range:

-

3~20mm

-

Maximum drilling depth:

-

500mm

-

Drill box (cutter) feed speed range:

-

10~500mm/min

-

Feed carriage fast moving speed:

-

3000mm/min

-

Feed motor torque:

-

10Nm

-

Number of spindle heads:

-

single head

-

Drilling aspect ratio:

-

≤100

-

Bedside box motor power:

-

2.2kW

-

Drill box motor power (servo):

-

3.7kW

Quick Details

-

type:

-

Drilling & Milling Machine

-

Max. Drilling Dia. (mm):

-

40-100

-

Range of Spindle Speed(r.p.m):

-

800 - 6000 r.p.m

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

DRC

-

Model Number:

-

ZK2102-500

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

3600mm/3200mm/1800mm

-

Power (kW):

-

19kW

-

Weight (KG):

-

6000 KG

-

CNC Gun Drilling Machine:

-

2 Spindle Gun Drilling Deep Hole Drilling Machine

-

Drill hole diameter range:

-

3~20mm

-

Maximum drilling depth:

-

500mm

-

Drill box (cutter) feed speed range:

-

10~500mm/min

-

Feed carriage fast moving speed:

-

3000mm/min

-

Feed motor torque:

-

10Nm

-

Number of spindle heads:

-

single head

-

Drilling aspect ratio:

-

≤100

-

Bedside box motor power:

-

2.2kW

-

Drill box motor power (servo):

-

3.7kW

Product Description

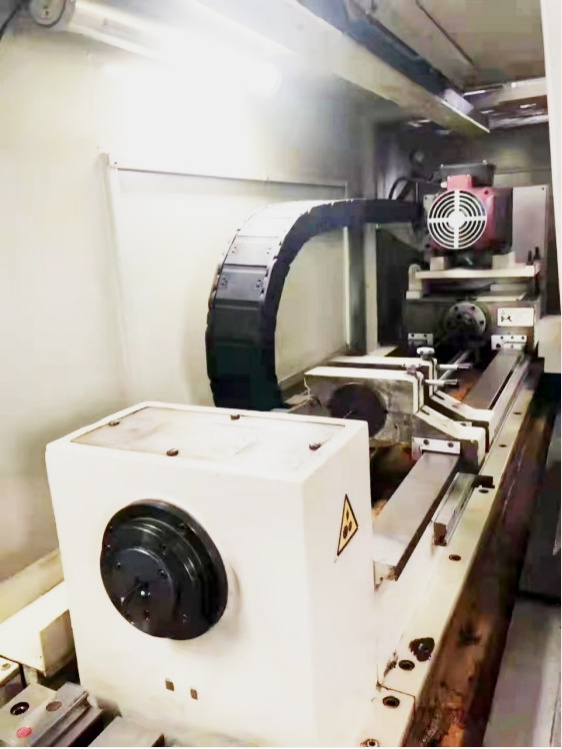

CNC 2 Spindle Gun Drilling Deep Hole Drilling Machine CNC Gun Drilling Machine

The main components of the machine tool:

1.Bed body. The structure of the bed is closed on three sides and has reasonably arranged stiffeners, so its rigidity is better. There are T-slot worktables and sliding tables for the feeding of the drill rod box carriage on it. There are The wide and deep oil return groove ensures that the coolant flows back to the oil tank smoothly.

2.Bedside box. It is installed on the T-slot table, and adjusts the position of the headstock according to the length of the workpiece. The tightening and loosening of the workpiece is realized through the control of the oil cylinder. The main shaft is driven by an AC asynchronous motor (with brake) to rotate at a certain speed, and its speed is about 380r/min.

3.Drill pipe box. The main shaft is driven by a servo motor, and the speed range is 300-5000r/min.

4.Feed system. It adopts Guangzhou numerical control system control, AC servo motor, ball screw pair, linear guide rail pair of transmission, and the range of feed speed is adjustable. The structure of the slide table is closed on three sides and has triangular ribbed plates. The entire feed system has the advantages of high precision, good rigidity, stable movement, and good precision retention.

5.Cooling system. There are 11kw frequency conversion motors for high-pressure oil pumps and gear pumps and other hydraulic components on the oil tank, which are filtered by non-woven paper, filter, and labyrinth. The iron filings rush down to the automatic chip conveyor, and finally collect in the chip storage car.

6.Centralized lubrication system. The front and rear bearings of the main shaft of the drill rod box, the guide rail surface of the carriage, and the ball screw nuts are all lubricated automatically at regular intervals and quantitatively.

7. Electrical system. Adopting Guangzhou CNC system, it can not only complete the automatic processing cycle by programming, but also manually, jog, open and close adjustments, etc. The machine operation button station is easy to operate.

Delixi electrical components are used.

8.Guide frame. Drill guide frame is used for drill guidance and drill pipe support. During the drilling process, the cutting fluid is delivered to the cutting area by the oil pump through the inner hole of the drill pipe, and then the cutting fluid carries the chips through the V-shaped groove of the drill pipe to the cavity of the guide frame and the bed body, and finally discharged to the chip storage car Inside.

9.Drill pipe support. A set of drill pipe support; it plays the role of drill pipe support and shock absorption.

10. Protection. full protection

Basic performance of the machine tool:

This machine tool is a high-efficiency, high-precision, high-automation special deep-hole drilling machine. It adopts the external chip removal drilling method (gun drilling method). Through one continuous drilling, it can replace the processing that generally requires drilling, expanding and reaming processes. precision and surface roughness. This machine tool is controlled by a digital control system, not only has a single action function, it also has an automatic cycle function. Therefore, it can be suitable for small batch processing, especially suitable for the processing requirements of mass production. It can drill through holes as well as blind or stepped holes.

|

Drill hole diameter range

|

φ3~20mm

|

|

Maximum drilling depth

|

500mm

|

|

Drilling tube main shaft speed range

|

300-5000r/min

|

|

Drill box (cutter) feed speed range (stepless)

|

10~500mm/min

|

|

Height from T-slot table top to spindle center

|

240mm

|

|

Feed carriage fast moving speed

|

3000mm/min

|

|

Feed motor torque

|

10Nm

|

|

Total power of machine tool (approx.)

|

19kW

|

|

Drill box motor power (servo)

|

3.7kw

|

|

Bedside box motor power

|

2.2Kw

|

|

Maximum flow rate of cutting cooling system

|

100L

|

|

Number of spindle heads

|

single head

|

|

Drilling aspect ratio

|

≤100

|

|

Dimensions (length x width x height)

|

3600mmx3200mmx1800mm

|

Certificate

Company Introduction

Hot Searches