- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

1600*1000

-

Cutting Thickness:

-

20mm

-

Control Software:

-

PLC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chanxan

-

Weight (KG):

-

450 KG

-

Core Components:

-

co2 laser

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Laser power:

-

60W-80W

-

Laser type:

-

Closed CO2 laser pipe

-

Weight::

-

350kg

-

working temperature::

-

1-45℃

-

speed::

-

0-1000mm/s

-

Work voltage:

-

220V 50hz

-

Name:

-

carpet cutting machine

-

Use to::

-

cutting,engraving,punching

-

Update time:

-

10.22

-

Certification:

-

CCC, ce, ISO, Sgs

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Viet Nam, India

-

Showroom Location:

-

Viet Nam, India

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Laser Type:

-

CO2

-

Cutting Speed:

-

800mm/s

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

1600*1000

-

Cutting Thickness:

-

20mm

-

Control Software:

-

PLC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Chanxan

-

Weight (KG):

-

450 KG

-

Core Components:

-

co2 laser

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Video technical support

-

Laser power:

-

60W-80W

-

Laser type:

-

Closed CO2 laser pipe

-

Weight::

-

350kg

-

working temperature::

-

1-45℃

-

speed::

-

0-1000mm/s

-

Work voltage:

-

220V 50hz

-

Name:

-

carpet cutting machine

-

Use to::

-

cutting,engraving,punching

-

Update time:

-

10.22

-

Certification:

-

CCC, ce, ISO, Sgs

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Viet Nam, India

-

Showroom Location:

-

Viet Nam, India

-

Marketing Type:

-

Hot Product 2019

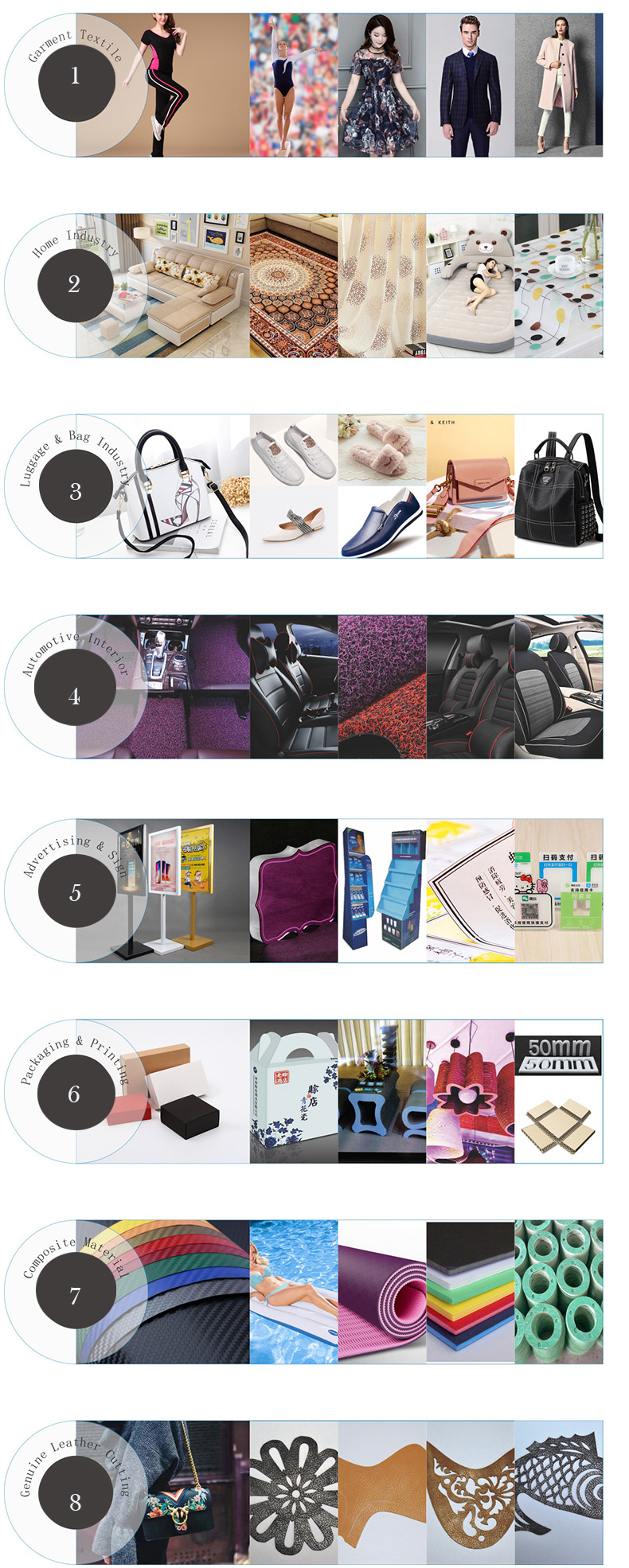

cutting , template

cutting , template

and paper goods cutting.

and paper goods cutting.

Product details

| size | 2250 x1650x1130 mm |

| Laser power | 60W-150w |

| Laser type | Closed CO2 laser pipe |

| Weight: | 350kg |

| working temperature: | 1-45℃ |

| speed: | 0-1000mm/s |

| Work voltage | 220V 50hz |

| Name | carpet cutting machine |

| Use to: | cutting,engraving,punching |

| Product Keywords | cloth sawing machines,cloth roll cutting machine,cloth processing and fast |

Features Cutting of acrylic AD decoration products,Plexiglas art-ware products,glasses products, ariplane and building model, architecture decoration material, bamboo and wood products cutting, PC/PVC/PP.plastic material cutting,packing printing , rubber, various hard material hard material and products cutting. Process area 600mm*400mm 1300mm*900mm laser type/power CO2 laser glass tube 60W CO2 laser glass tube 60W cutting speed 0-800mm/s 0-800mm/s engraver speed 0-1000mm/s 0-1000mm/s positioning accuracy <0.02mm <0.02mm Supported formats DXF/PLT/BMP/AI/HML/DST DXF/PLT/BMP/AI/HML/DST Cooling system water cooling and protection system water cooling and protection system whole power 1500W 1500W Net weight 175KG 300KG work temperature 1℃-45℃ 1℃-45℃ machine dimension 1200mm*940*1100mm 1900mm*1500*1130mm

Equipment Advantage:

1,Automatic camera laser cutting, using the third generation of highly intelligent control system, make the camera in high accurate position, with the move of camera and the collaborative role of visual system and computer software ,the laser cutting machine will make up for the small extrude for the fabric during the processing, ensure the whole processing is in high accuracy and no mistake.

2,This combination of automation and artificial visual technology make sure the machine run more stable, in higher precision and in higher speed ; It improves production efficiency in 10%-20%. Which meets the requirements of improving output for all the users

Quality assurance: We arrange final test before shipment. We run the machine without material for a few days, and then cut materials for test. After making sure machine is the best performance, then ship out the machine.

1. With a third generation of highly intelligent control system,automatic control,high precision positioning,forming edges smooth,compared with the traditional process,the product more attractive beautiful

2.Compare with the conventional process,more beautiful,

more efficient,more saving materials

more efficient,more saving materials

3.As the laser in the process of cutting ,caving ,no touch with the surface to ensure that every product is the highest quality,enhance the competitiveness of enterprises!