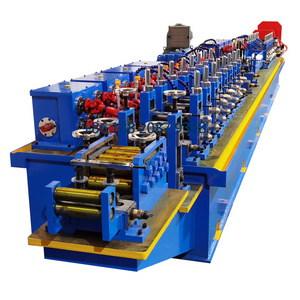

- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Pipe Material:

-

Stainless steel

-

Place of Origin:

-

Turkey

Product Description

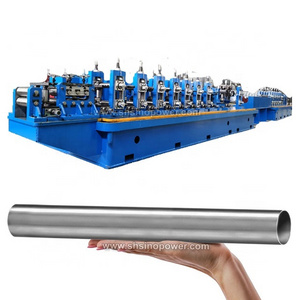

PIPE AND PROFILE ROLLS (DIN 2379 material)

PIPES (5 SET)

Ø48 mm

Ø51 mm

Ø63 mm

Ø76 mm

Ø127 mm

PROFILES

40x40 mm

50x50 mm

60x60 mm

100x100 mm

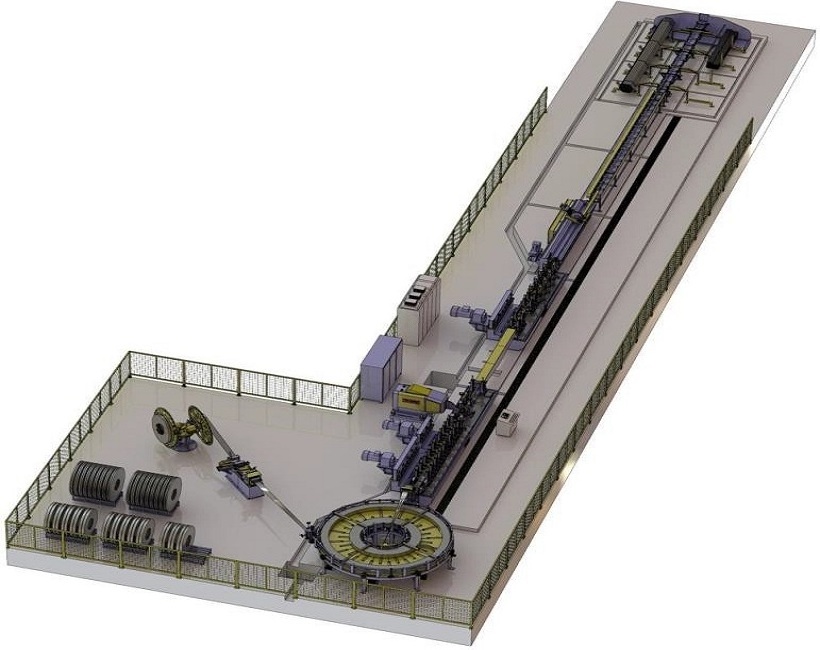

Detailed Images

Packing & Delivery

Hot Searches