- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

6100 mm

-

Backgauge Travel (mm):

-

10 - 800 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

15 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/400V, 220V/380V/400V

-

Dimension(L*W*H):

-

6800x2200x2500 mm

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Shearing thickness:

-

12mm

-

Rated Power:

-

22kw

-

Shearing width:

-

6000mm

-

Shearing angle:

-

0.5-3.0

-

Weight:

-

25T

-

After Warranty Service:

-

Field maintenance and repair service

-

Control system:

-

Delem DAC360T

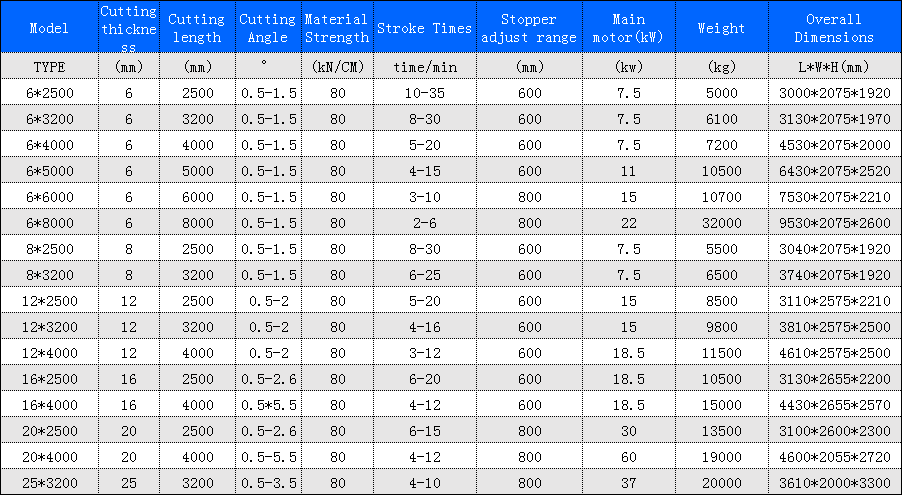

Quick Details

-

Max. Cutting Width (mm):

-

6000

-

Max. Cutting Thickness (mm):

-

4 mm

-

Shearing Angle:

-

0.5-1.5

-

Blade Length (mm):

-

6100 mm

-

Backgauge Travel (mm):

-

10 - 800 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

CNCColgar

-

Power (kW):

-

15 kW

-

Weight (KG):

-

6000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220/230/380/400V, 220V/380V/400V

-

Dimension(L*W*H):

-

6800x2200x2500 mm

-

Year:

-

2024

-

Marketing Type:

-

New Product 2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Shearing thickness:

-

12mm

-

Rated Power:

-

22kw

-

Shearing width:

-

6000mm

-

Shearing angle:

-

0.5-3.0

-

Weight:

-

25T

-

After Warranty Service:

-

Field maintenance and repair service

-

Control system:

-

Delem DAC360T

Products Description

|

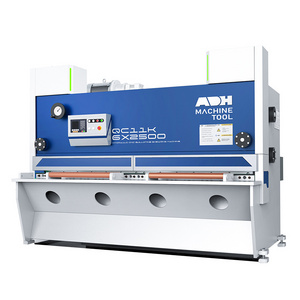

Hydraulic Guillotine Shearing Machine Features:

|

|

|

|

|

||||

1, The machine is fitted with CNC controller special for shearing machines.

2, The position of rear stopper is displayed in real-time manner.

3, Multi-step programming function is available and the rear stopper is able for automatic operation and continuous positioning, to achieve an automatic adjustment for position of rear stopper.

4, It is provided with a counting function for shearing, to display the shearing numbers in a real-time manner, able for power-failure memory of position of rear stopper, procedures, and parameters.

5, Back gauge with precision ball screw and linear guide, to ensure the positioning precision, so that brings the higher accuracy of processing.

Details Images

Name: Working table with ball roller

Make more easier for the worker to input the plate into cutting area

Name: CNC system

Matching automatic feeding, servo motor, multi-language optional

Name: Electronic system

Brand: Schneider

Original: France

Well-known brands, good materials, high safety

Name: Blade gap adjustment motor

The system adjusts the blade gap, high efficiency and precision

Name: Servo driver

Achieve high positioning accuracy of the back gauge distance

Name:Main motor

Brand: Siemens

Original: Germany

High efficiency, low noise, easy maintenance

Name: Hydraulic Valve

Brand: BOSCH REXROTH

Original: Germany

Hydraulic transmission with high reliability, safe and efficient with good quality

Name: Oil pump

Low noise during operation, long service life, convenient maintenance and low loss

Name:Oiling device-add 150usd

The machine is lubricated by hand toensure the smooth use of the machine

Name: Pneumatic rear support-based on machine length

Lift the plate to improve cutting accuracy

DAC360 System

E200PS System

E21S Dual Servo System

Anhui Colgar Machinery Manufacturing Co., Ltd.

is a modern enterprise focusing on R&D, manufacturing, sales and service of a complete set of metal sheet metal equipment. lt mainly produces bending machines, shearing machines, laser and plasma cutting machines, forging press machines, rolling machines, air duct equipment, etc. Other sheet metal processing machines. lt has a modern production plant and is equipped with advanced processing equipment from Germany and Spain. The production is based on the IS09001 management system, and the products have obtained EU CE certification and SGS certification. Factory locates on Maanshan city, Anhui province, covers an area of 50,000 square meters with more than 120 workers.

Web:

https://www.rbglty.com

Facebook:

https://www.facebook.com/colgar888

Youtube channel:

www.youtube.com/@cnccolgar

FAQ&Contact us

Q:How to choose a shearing machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

Hot Searches