- Product Details

- {{item.text}}

Quick Details

-

Number of Cells:

-

5" 6" and half cells

-

Max Working Efficiency:

-

800Cells/hour

-

Cell Breakage Rate:

-

<0.2%

-

Bus bar Exchanger Time:

-

<30min

-

Solar Strings Length:

-

Adjustable

-

Ribbon Length:

-

Adjustable

-

Usage:

-

Solar Cell soldering

-

Dimensions:

-

3880*1320*1800mm

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power(W):

-

15MW~ 30MW

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

ARGUS

-

Model Number:

-

STS800

-

Number of Cells:

-

5" 6" and half cells

-

Max Working Efficiency:

-

800Cells/hour

-

Cell Breakage Rate:

-

<0.2%

-

Bus bar Exchanger Time:

-

<30min

-

Solar Strings Length:

-

Adjustable

-

Ribbon Length:

-

Adjustable

-

Usage:

-

Solar Cell soldering

-

Dimensions:

-

3880*1320*1800mm

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Power(W):

-

15MW~ 30MW

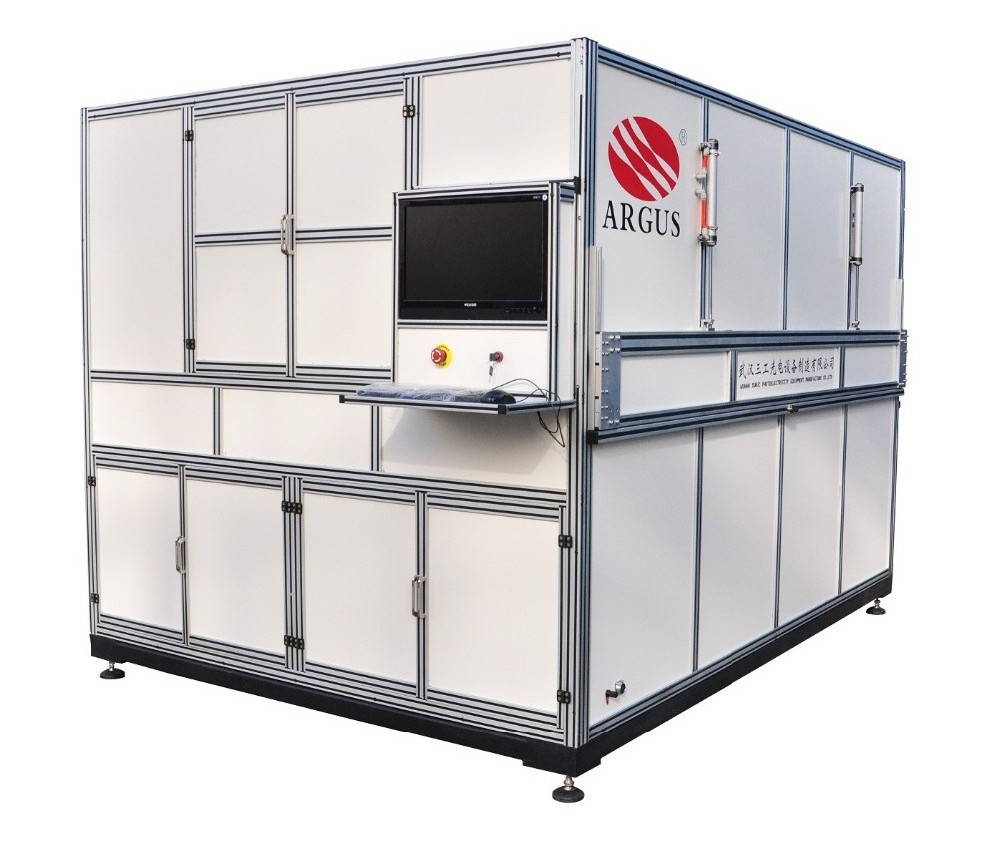

Equipment Performance

Tabber&Stringer STS800 adopts stress-free Hot-wind Wheel Soldering method, Servo motor Driving and Industrial CCD positioning&detection for defective solar cell excluding automatically. The soldering effect, such as Cell spacing, Cell numbers of single string, Soldering temperatures and etc, can be adjusted according to requirements. STS800 can be integrated with Automatic Layup machine to achieve the composing and locating of Solar cell Strings on Tempered glass.

Equipment Advance

22,Solar cell soldering numbers per string can be set by PC

Equipment Hardware Specification

1.Machine body

3.Cell Tilted Positioning CCD structure

4.Soldering processing structure

5.Solar cell soldering structure

6.Unloading structure

Error Alarm function

ABOUT US

Wuhan Sunic Photoelectricity Equipment Manufacture Co.,Ltd (Sunic Laser) have been engaged in manufacture of laser equipments since 1998. We are specialized in designing, manufacture, sales and service for laser processing machines and whole equipments for Solar PV production line, and supply complete turnkey solutions with laser application for customers all over the world.