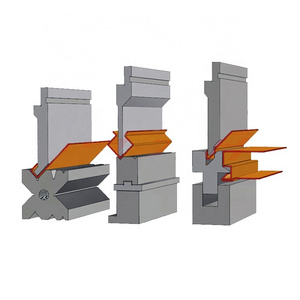

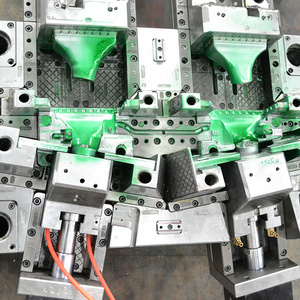

1.Most tools can be easily loaded by a single operator.

2. Easy to store.

3. All sectionalised tools come pre-cut in

nine different pieces.

4. Most sectionalised punches include two

ear pieces (horns).

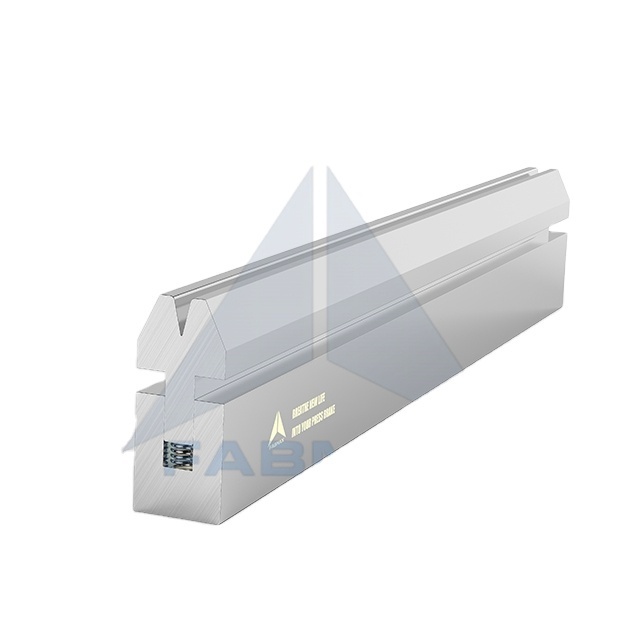

5. Punches are induction hardened, to 59-60

HRC but NITREX™ (HRC-60) is available

for every punch in the tooling line.

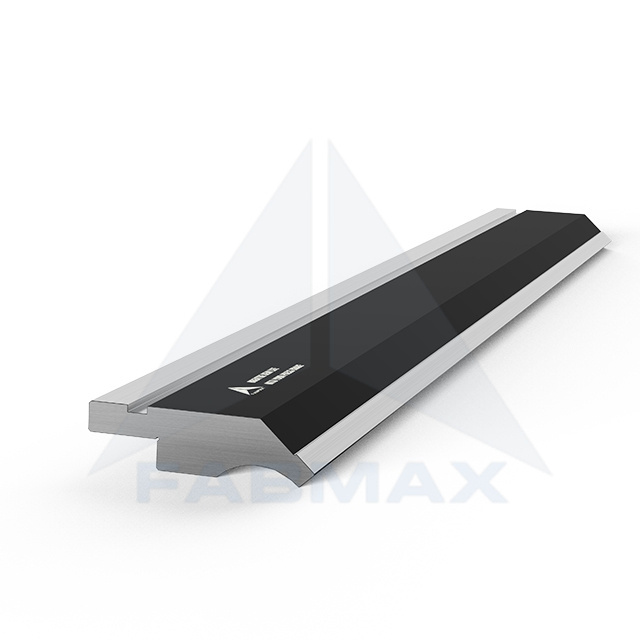

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FP125-90-R02

-

Product Name:

-

Narrow punches

-

sectioned:

-

L100/270/10/15/20/40/50/200/R100

-

Warranty:

-

2 years

-

HRC:

-

47°±2°

-

Material:

-

42CrMo

-

Application:

-

Sheet metal fabrication

-

Color:

-

Metallic

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

MOQ:

-

1 Pcs

-

Mould Life:

-

3000 times

Quick Details

-

Shaping Mode:

-

Forging Mould

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

FABMAX

-

Model Number:

-

FP125-90-R02

-

Product Name:

-

Narrow punches

-

sectioned:

-

L100/270/10/15/20/40/50/200/R100

-

Warranty:

-

2 years

-

HRC:

-

47°±2°

-

Material:

-

42CrMo

-

Application:

-

Sheet metal fabrication

-

Color:

-

Metallic

-

Drawing Format:

-

3D/CAD/DWG//STEP/PDF

-

MOQ:

-

1 Pcs

-

Mould Life:

-

3000 times

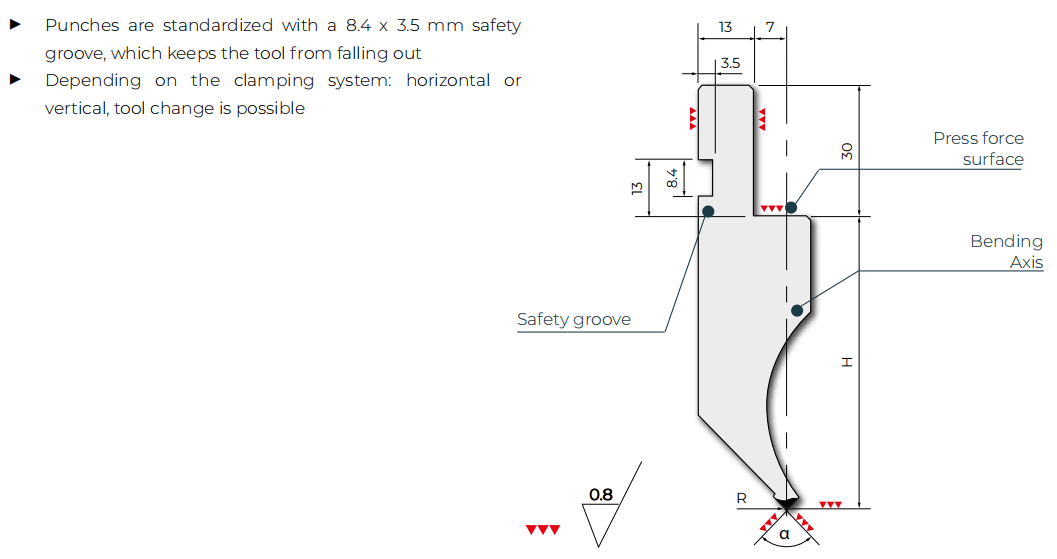

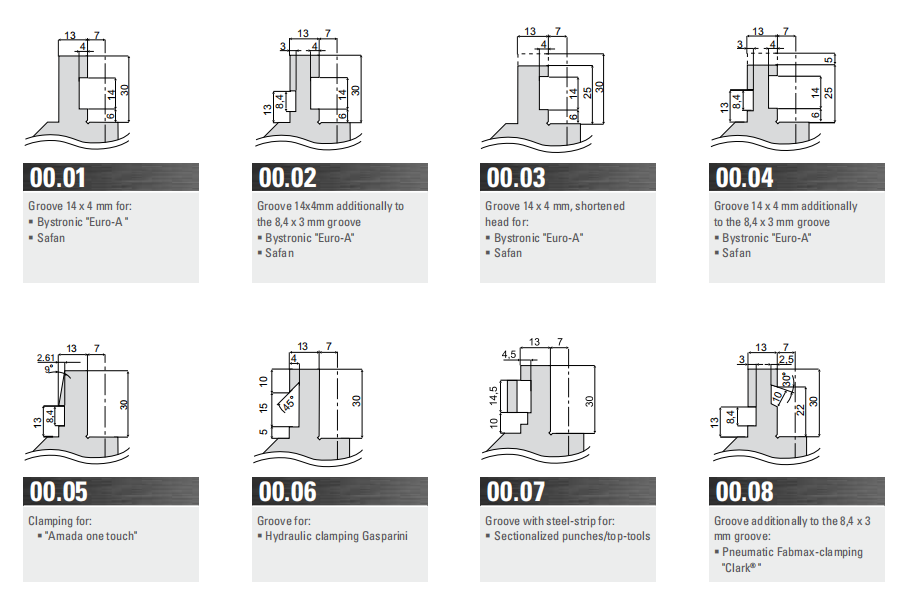

Content explanation punches

Advantages

Secure Investment

With over 25 years of experience, your investment is in secure hands. Sheetmetal Machinery provide competent, quick and

independent sales, service and spare parts support.

Dedicated Service Team

Correct preventative maintenance can reduce potential issues and down time. Our dedicated service team are capable of performing profession technical support.

Specialised Consultation

We provide personal and specialised consultation to ensure an optimal production solution to suit the needs of any business. Not

sure what suits your needs best, ask us today.

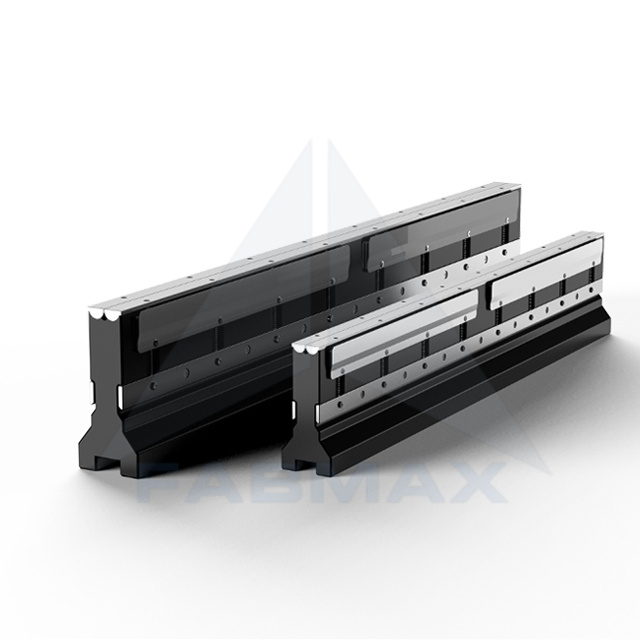

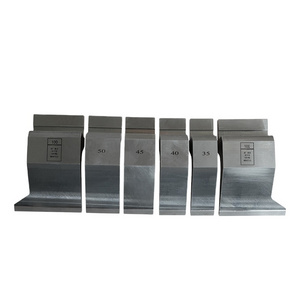

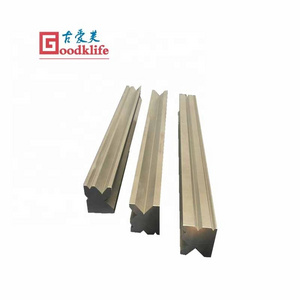

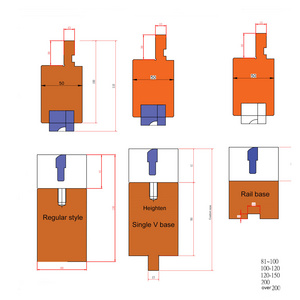

Segmentation of upper tools

PUNCH FEATURES:

PUNCH SECTION WIDTHS:

100mm LEFT EAR / 100mm RIGHT EAR / 10mm / 15mm / 20mm / 40mm / 50mm / 200mm / 300mm

Note: Special lengths are available at additional cost, just select the standard length and ask us to cut to your requirements.

Calculation basics for air bending

Calculation formulas

Recommended bottom tool opening V for air bending

|

Material thickness “S”

|

0.5-2.5mm

|

3-8mm

|

9-10mm

|

> 12mm

|

|

Bottom tool opening “V”

|

6×t

|

8×t

|

10×t

|

12×t

|

Bending force:

|

Aluminium

|

Rm=300N/mm2

|

F=F( 折弯表 /table)x0.65

|

|

Mild steel

|

Rm=420N/mm

|

F=F( 折弯表 /table)

|

|

Stainless steel

|

Rm=700N/mm2

|

F=F( 折弯表 /table)x1.6

|

Determination of the bending force for air bending(reference data)

F=Rm*t2 /V×(1+4*t/V)

Conversion:Rm=tensile strength in N/mm2 10N≈1Kg 10kN≈1t

Tensile strength:

|

Material

|

|

|

Tensile strength

|

||

|

China

|

European

|

American

|

N/mm2

|

||

|

LD30

|

Alu 50

|

6061 Aluminum

|

290

|

||

|

LF2

|

Alu 35

|

5052 Aluminum

|

303

|

||

|

10/10F

|

DC01

|

1010 Mild steel

|

366

|

||

|

QT400-18

|

GGG-40

|

A 536-80 G 60-40-18

|

400

|

||

|

Q235

|

G-X 6CrNi 18 9

|

A 351 G CF 8

|

450

|

||

|

Q345

|

S 355 MC

|

A 572 G50

|

550

|

||

|

0Cr18Ni9

|

Inox V2A

|

304 Stainless

|

586

|

||

|

0Cr17Ni12Mo2

|

Inox V4A

|

316 Stainless

|

600

|

||

|

42CrMo

|

42 CrMo 4

|

4140 Low alloy

|

1000

|

||

Performance

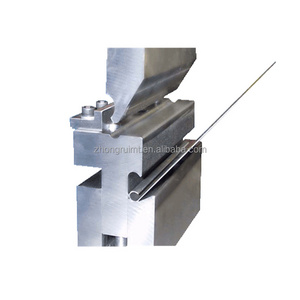

Heavy compressive stresses within the nitrided surface layer considerably improve fatigue strength.

They must exhibit high surface hardness and good core strength. The improved surface hardness and wear resistance impart outstanding sliding and running properties to the steel parts.

Our quality control department checks and tests every

single tool after a complete production cycle. After a

careful inspection, every tool is marked with a serial

number and a batch number. This process guarantees

complete tool traceability.

When bending heavy material, laser hardening is the best solution. This method involves hardening the concentrated points of the tool, primarily the punch tips and shoulder radii on the dies. This process creates a hardness of 55-60 HRC with a depth of approximately .060”.

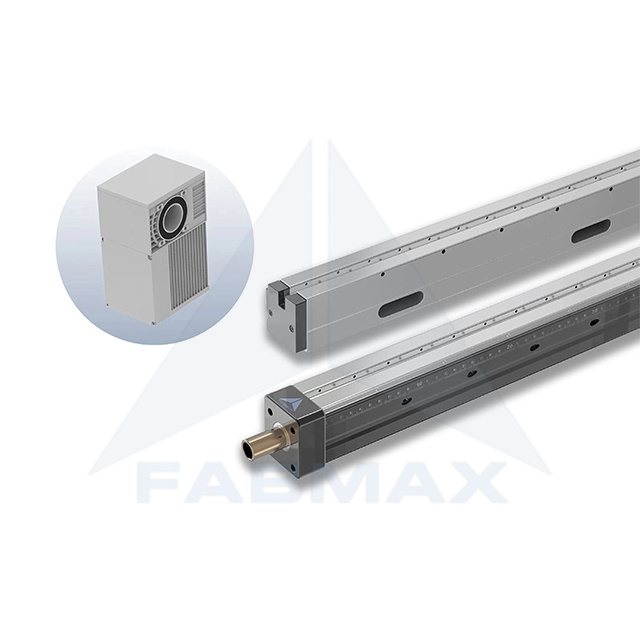

We propose bending tools for any model of press brake, bending punches, dies,crowning-table,adapters, mountings and bending stamps, special bending tools, bending equipment, also we produce shear blades for all types of shears.If the tooling or parts are on our shelf, every effort is made to get them shipped the day they are ordered.

Our company

Exhibition

Terms and conditions

CREDIT/PAYMENT

All purchases are COD unless credit approved. If account is past due, Fabmax(China) Co.,Ltd. reserves the right to hold shipment or require COD terms. Credit/Payment terms are Net 30 days from date of invoice. Past due accounts are subject to interest charges. No early payment or cash discounts are allowed.

ORDERS

Minimum of $2000.00. Please write your Fabmax(China) Co.,Ltd . customer account number on all purchase orders to speed processing. Also, please specify machine model, material type and thickness.

F.O.B.

All orders are F.O.B. shipping point.

SPECIAL ORDERS

All special orders are non-cancelable, non-returnable, and non-refundable.

RETURNED MATERIAL

Accepted only with prior approval of Fabmax(China) Co.,Ltd ’ s Tooling Department Manager. There will be a 25% re-stocking fee on all standard items. All items must be returned unused and freight prepaid. No returns will be allowed beyond 30 days of original shipment.

DELIVERY

Delivery on special items will be established at time of order.

PURCHASE ORDER NUMBER

Purchase order number must accompany all telephone orders. Verbal orders will not be processed without a purchase order number.

DAMAGE OR SHORTAGE CLAIMS

All claims must be made within ten calendar days of receipt of tooling.

PRICING

All prices in this catalog are subject to change without notice. All prices provided by Fabmax(China) Co.,Ltd . in the form of a written quotation are valid for thirty days following the date of the quote.

All purchases are COD unless credit approved. If account is past due, Fabmax(China) Co.,Ltd. reserves the right to hold shipment or require COD terms. Credit/Payment terms are Net 30 days from date of invoice. Past due accounts are subject to interest charges. No early payment or cash discounts are allowed.

ORDERS

Minimum of $2000.00. Please write your Fabmax(China) Co.,Ltd . customer account number on all purchase orders to speed processing. Also, please specify machine model, material type and thickness.

F.O.B.

All orders are F.O.B. shipping point.

SPECIAL ORDERS

All special orders are non-cancelable, non-returnable, and non-refundable.

RETURNED MATERIAL

Accepted only with prior approval of Fabmax(China) Co.,Ltd ’ s Tooling Department Manager. There will be a 25% re-stocking fee on all standard items. All items must be returned unused and freight prepaid. No returns will be allowed beyond 30 days of original shipment.

DELIVERY

Delivery on special items will be established at time of order.

PURCHASE ORDER NUMBER

Purchase order number must accompany all telephone orders. Verbal orders will not be processed without a purchase order number.

DAMAGE OR SHORTAGE CLAIMS

All claims must be made within ten calendar days of receipt of tooling.

PRICING

All prices in this catalog are subject to change without notice. All prices provided by Fabmax(China) Co.,Ltd . in the form of a written quotation are valid for thirty days following the date of the quote.

Hot Searches