Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINHE

-

Voltage:

-

380V/CUSTOMIZED

-

Dimension(L*W*H):

-

2800*2300*1500MM

-

Power (kW):

-

55

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Extrusion Machine

-

Usage:

-

Make Sheet

-

Keywords:

-

Sheet Machine CHINA

-

Final product:

-

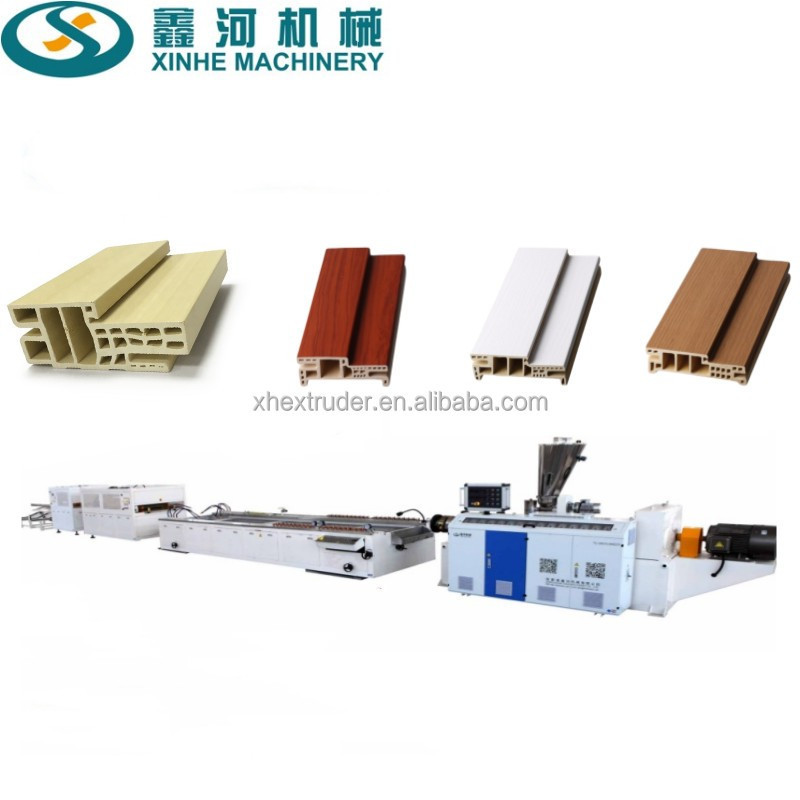

Wood Plastic Composite Products

-

Raw material:

-

PVC Powder

Quick Details

-

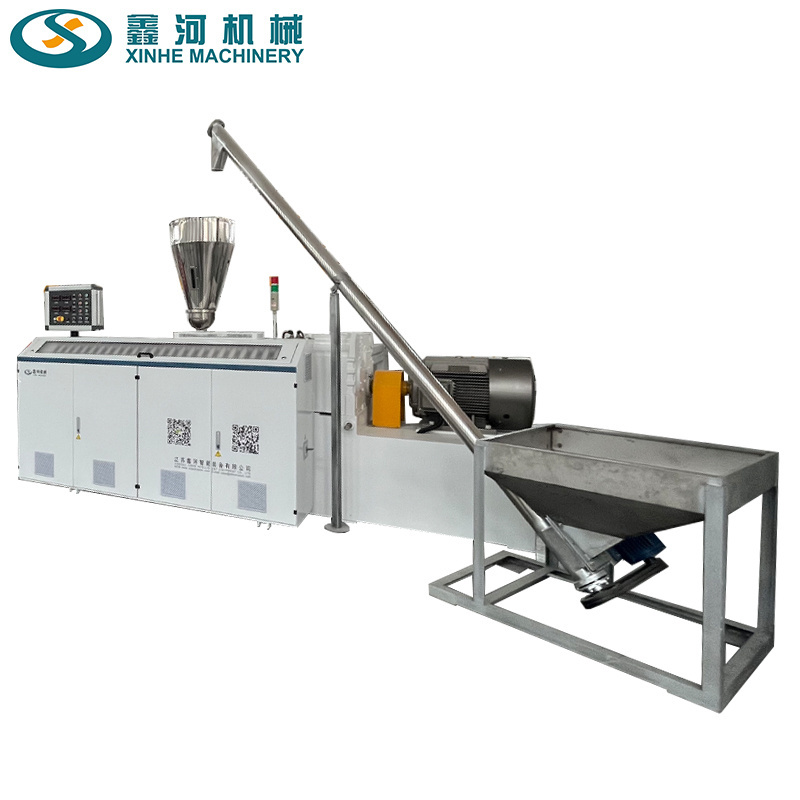

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

1800 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINHE

-

Voltage:

-

380V/CUSTOMIZED

-

Dimension(L*W*H):

-

2800*2300*1500MM

-

Power (kW):

-

55

-

Weight:

-

3 KG

-

After-sales Service Provided:

-

Online Support

-

Name:

-

Extrusion Machine

-

Usage:

-

Make Sheet

-

Keywords:

-

Sheet Machine CHINA

-

Final product:

-

Wood Plastic Composite Products

-

Raw material:

-

PVC Powder

Video Show

Overview

Want more details of door ,click here

https://siteadmin.alibaba.com/preview.htm?spm=a2700.siteadmin.0.0.3673102a1t1fsG&pageId=5124263647&type=pc

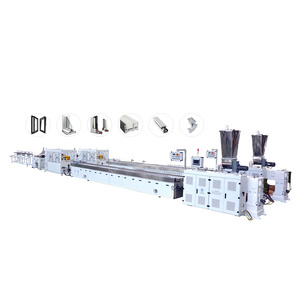

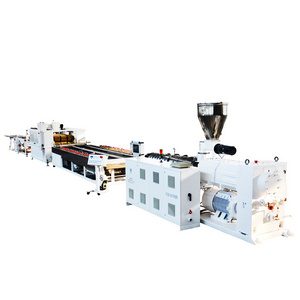

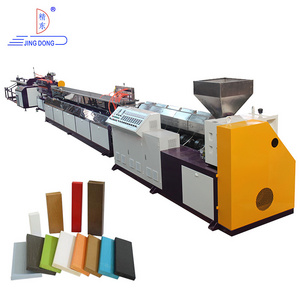

Advantages of PVC WPC window door board making machine:

The PVC wide door extrusion production line of XInhe adopts the latest manufacturing technology. It uses some parts of

international famous brand.The SJSZ80/156,92/188 conical twin-screw plastic extruder are specially designed. Because it use ABB,

SIEMENS frequency converter, RKC, and OMRON temperature control meter, it has the advantages of convenient and reliable operation

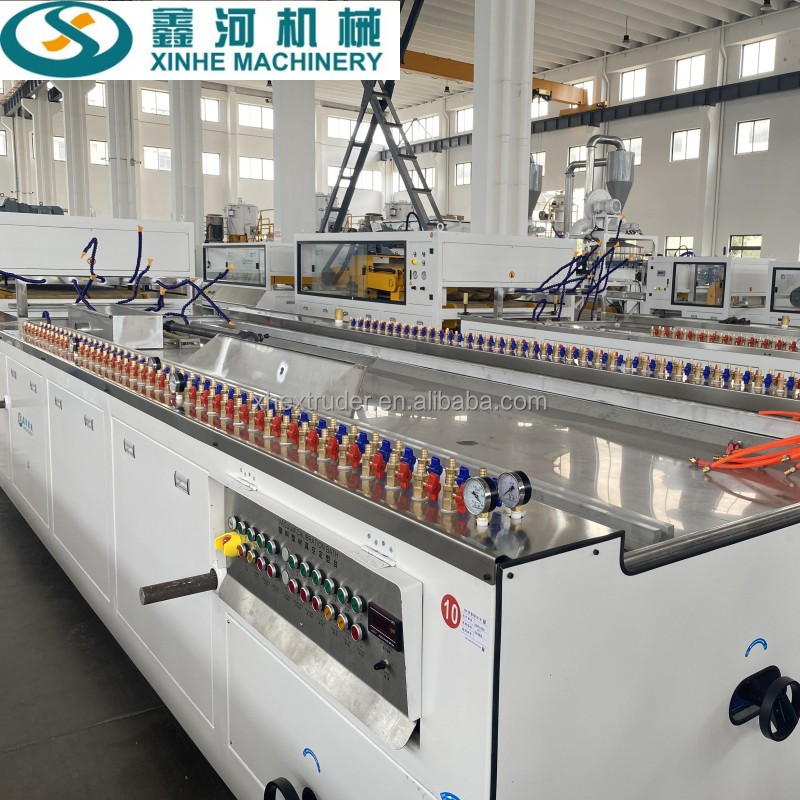

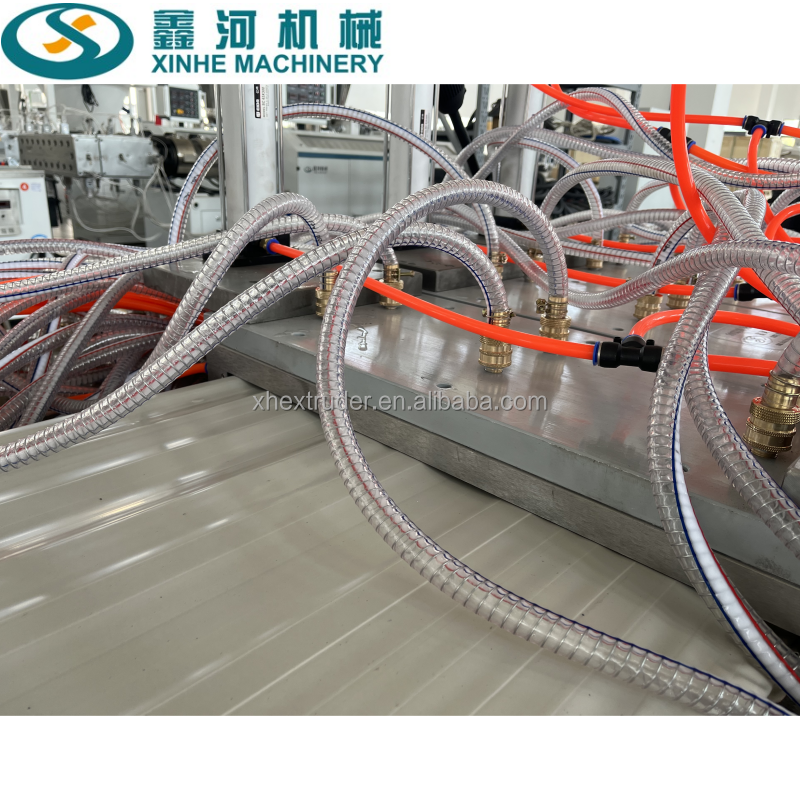

etc. The PVC wood door extrusion production line is made up of conical twin-screw plastic extruder, broad mould, calibrator,

cooling platform, craw tractor, transverse cutting machine, and stacker.

The PVC wide door extrusion production line of XInhe adopts the latest manufacturing technology. It uses some parts of

international famous brand.The SJSZ80/156,92/188 conical twin-screw plastic extruder are specially designed. Because it use ABB,

SIEMENS frequency converter, RKC, and OMRON temperature control meter, it has the advantages of convenient and reliable operation

etc. The PVC wood door extrusion production line is made up of conical twin-screw plastic extruder, broad mould, calibrator,

cooling platform, craw tractor, transverse cutting machine, and stacker.

|

Model

|

YF600

|

YF800

|

YF1000

|

YF1250

|

|

Extruder

|

SJZ80/156

|

SJZ80/156

|

SJZ92/188

|

SJZ92/188

|

|

Power

|

55

|

55

|

132

|

132

|

|

Capacity

|

280

|

280

|

600

|

600

|

Want more parameter details,click here

https://siteadmin.alibaba.com/preview.htm?spm=a2700.siteadmin.0.0.3673102a1t1fsG&pageId=5124263647&type=pc

Features:

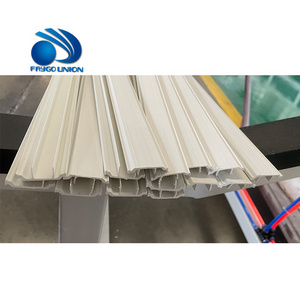

This production line is designed according to international latest technology, mixed PVC with plant fiber symmetrically.

It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form.

The wood plastic panel out from our line has features of green environment protection, damp proof, anti-fire and not

distortion, thus suitable for processing method of wood and can be recycled to reuse.

It has been widely used in home use.

It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form.

The wood plastic panel out from our line has features of green environment protection, damp proof, anti-fire and not

distortion, thus suitable for processing method of wood and can be recycled to reuse.

It has been widely used in home use.

Details Images

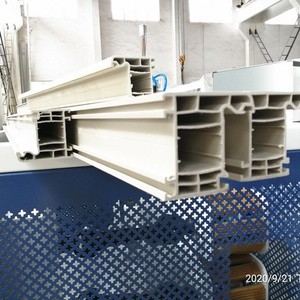

Final Product

Recommend Products

Hot Searches