2.

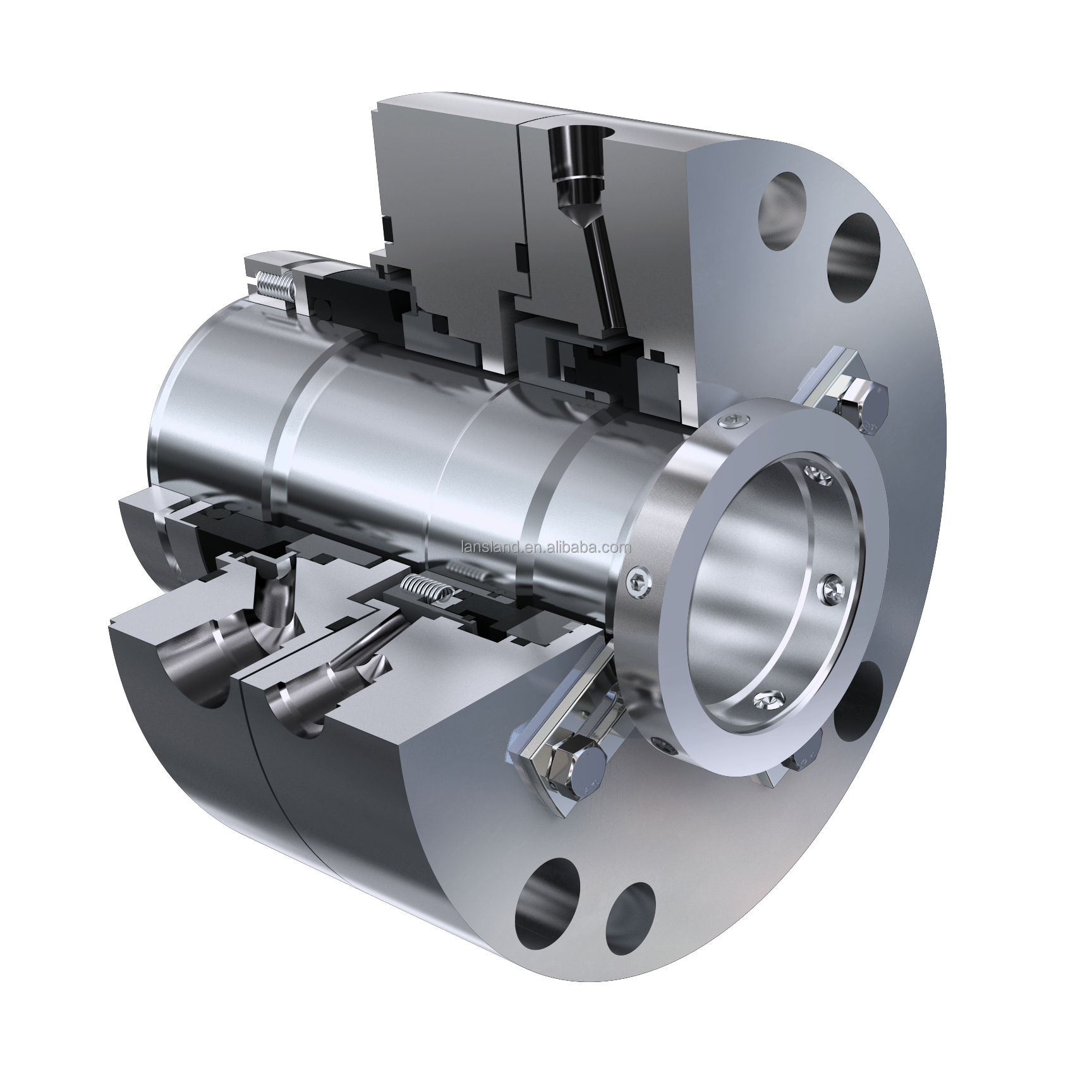

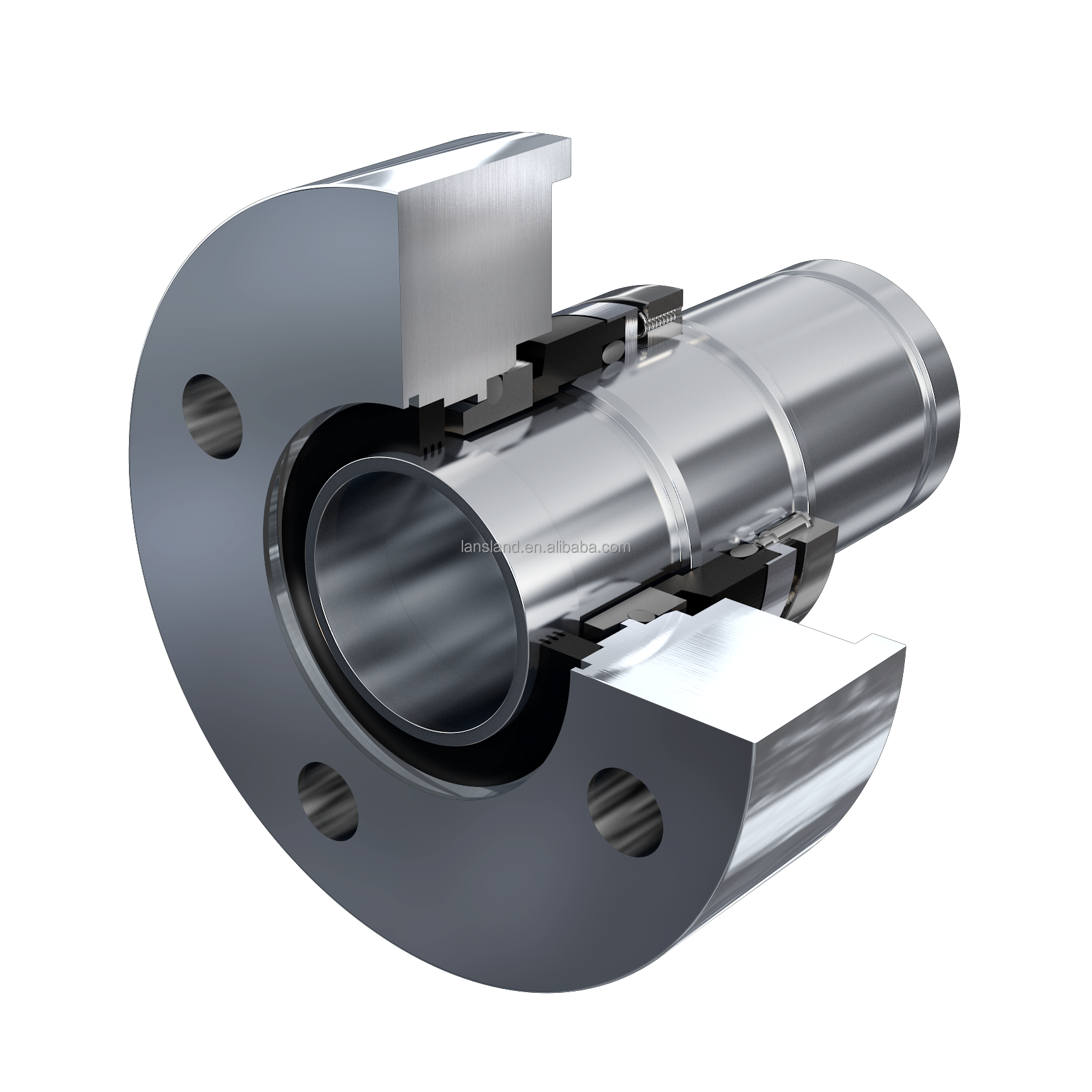

Multi spring:

Good compensation performance, uniform loading

3.

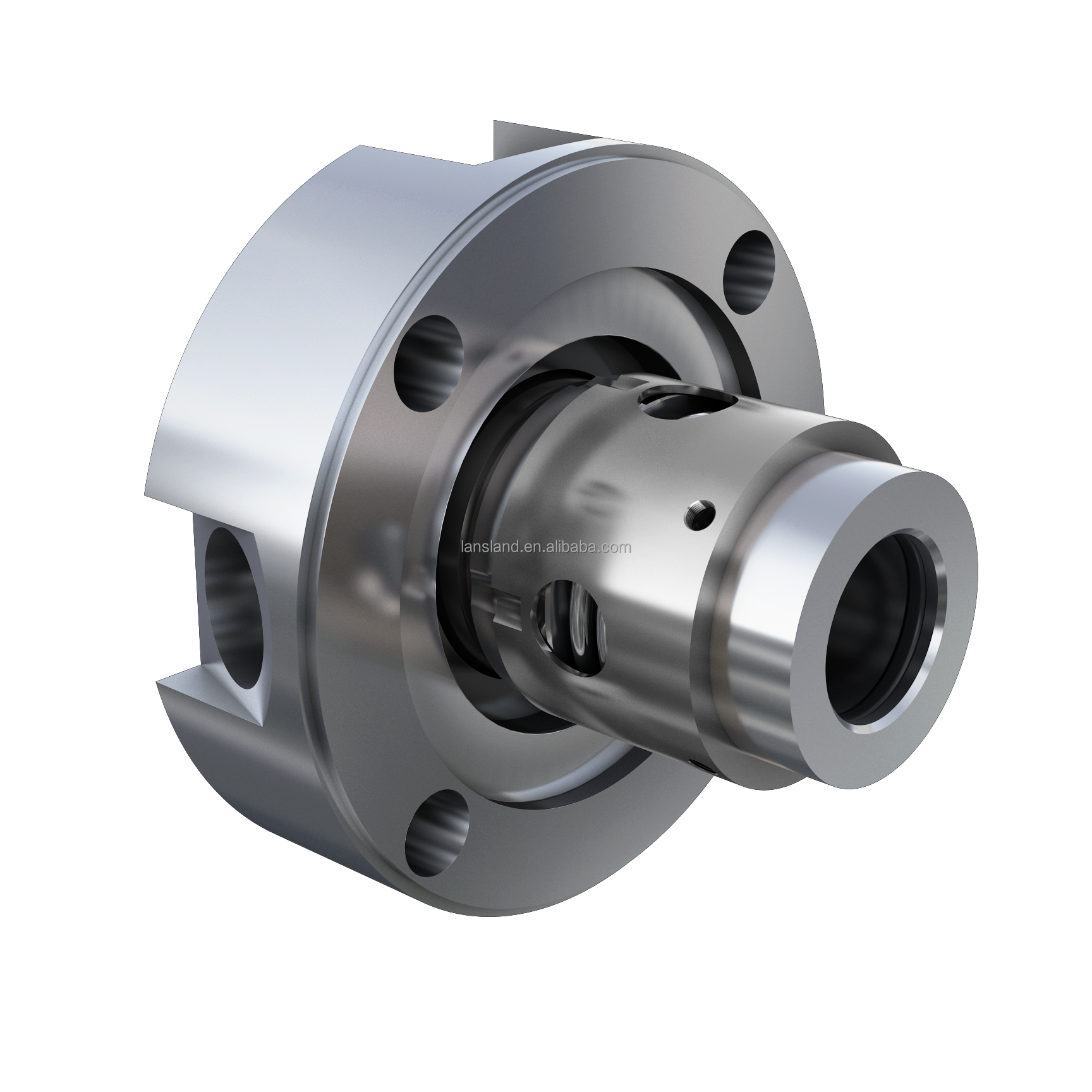

Composite transmission

:

Less frictional damping and more uniform power transmission

4.

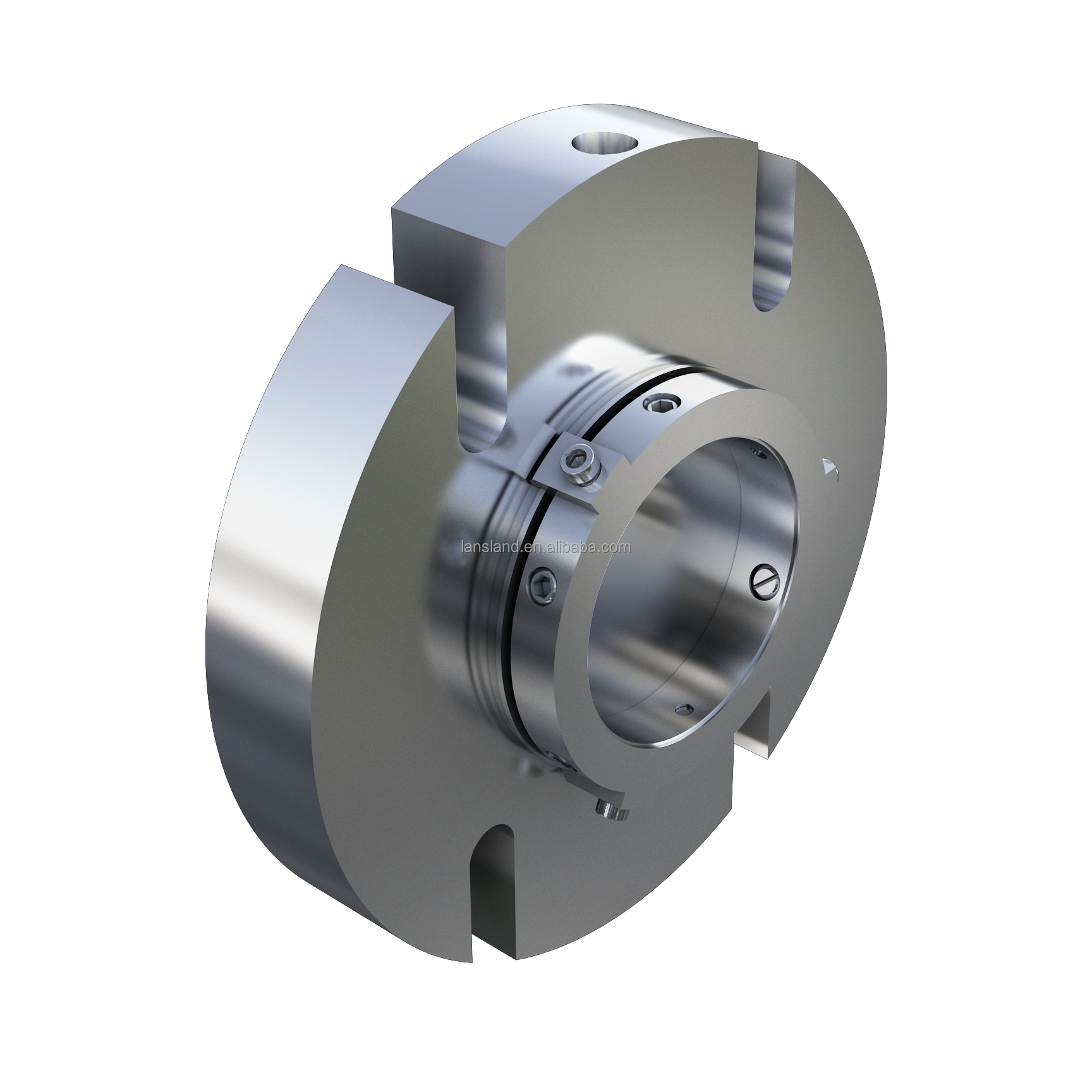

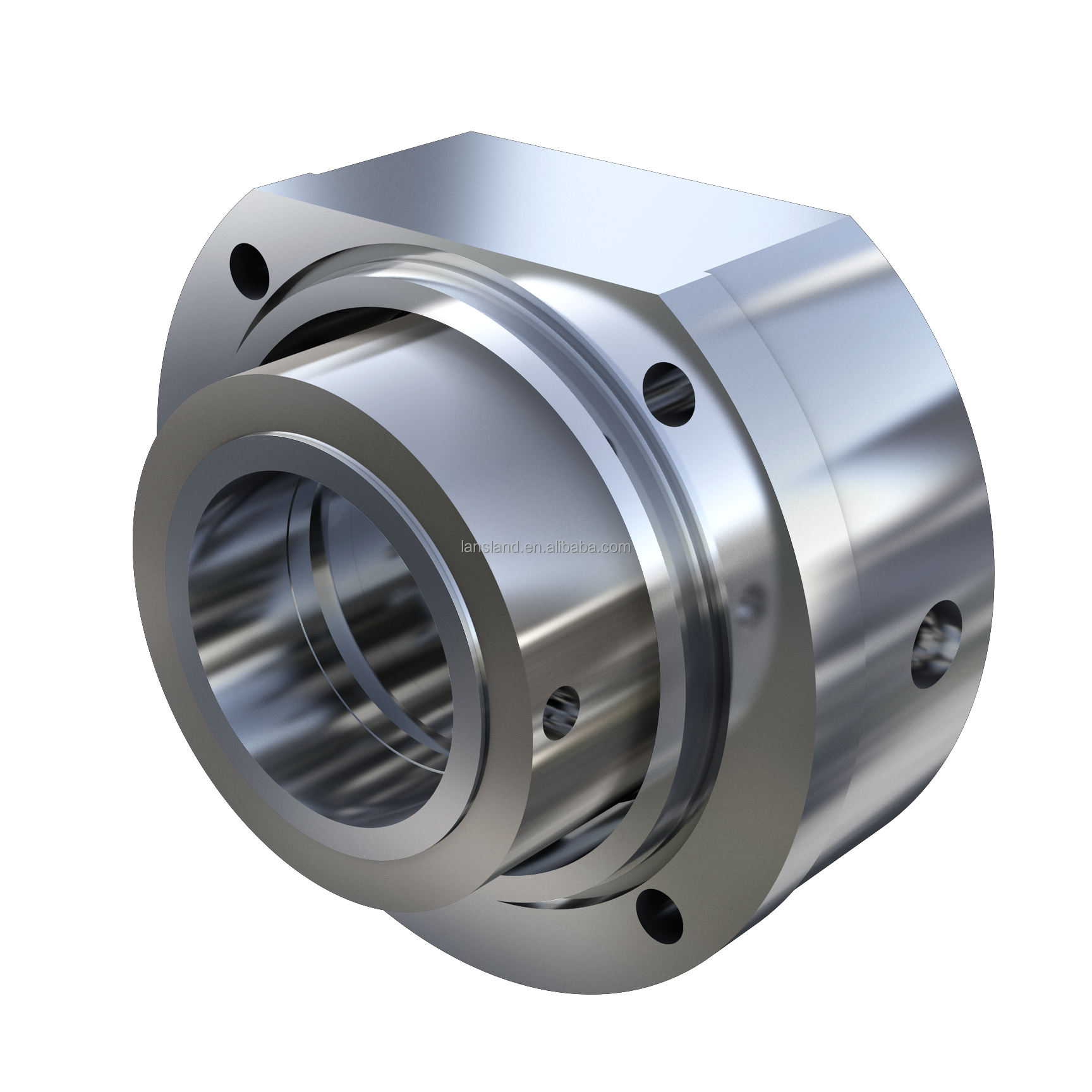

Positioning of screws:

Easy installation and easy adjustment

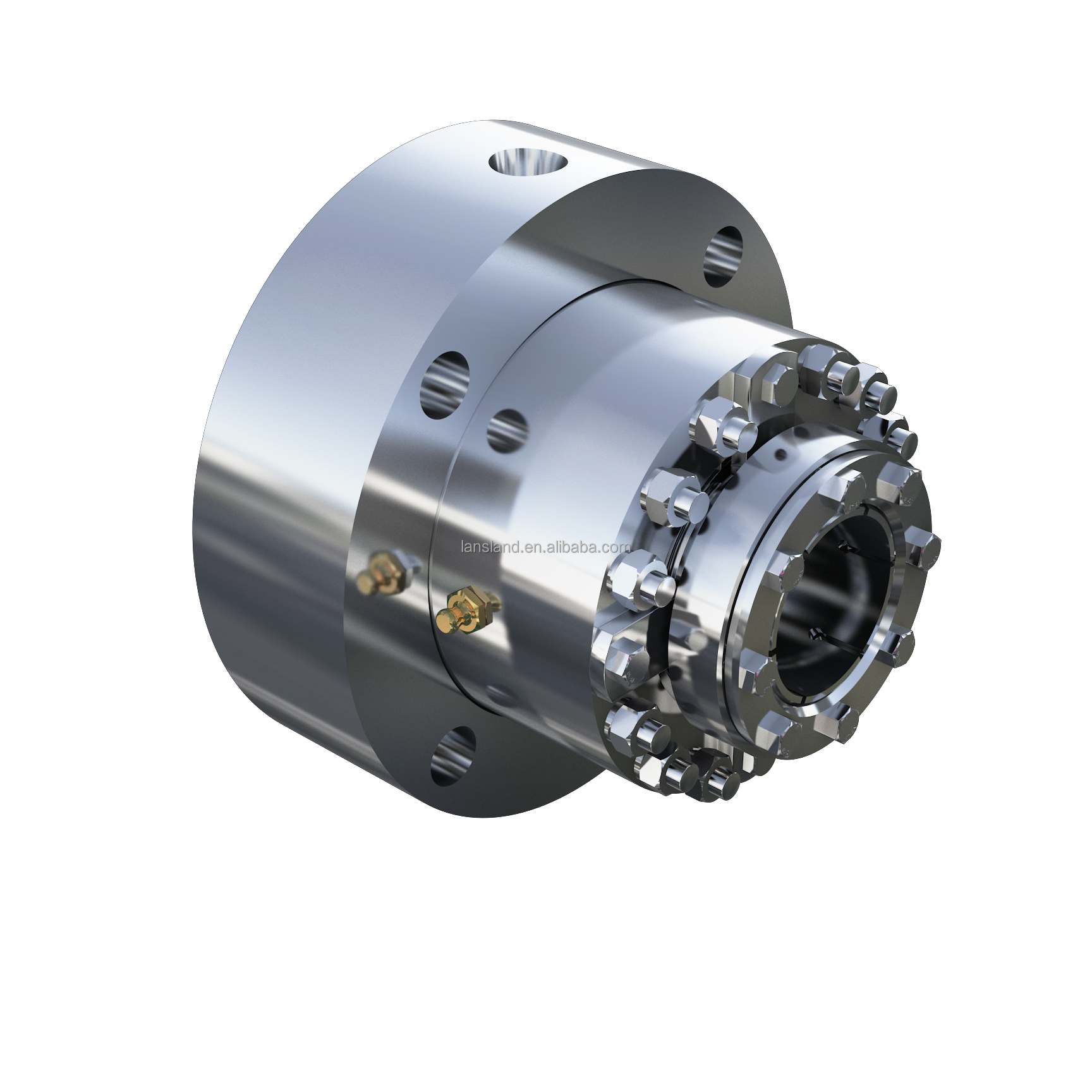

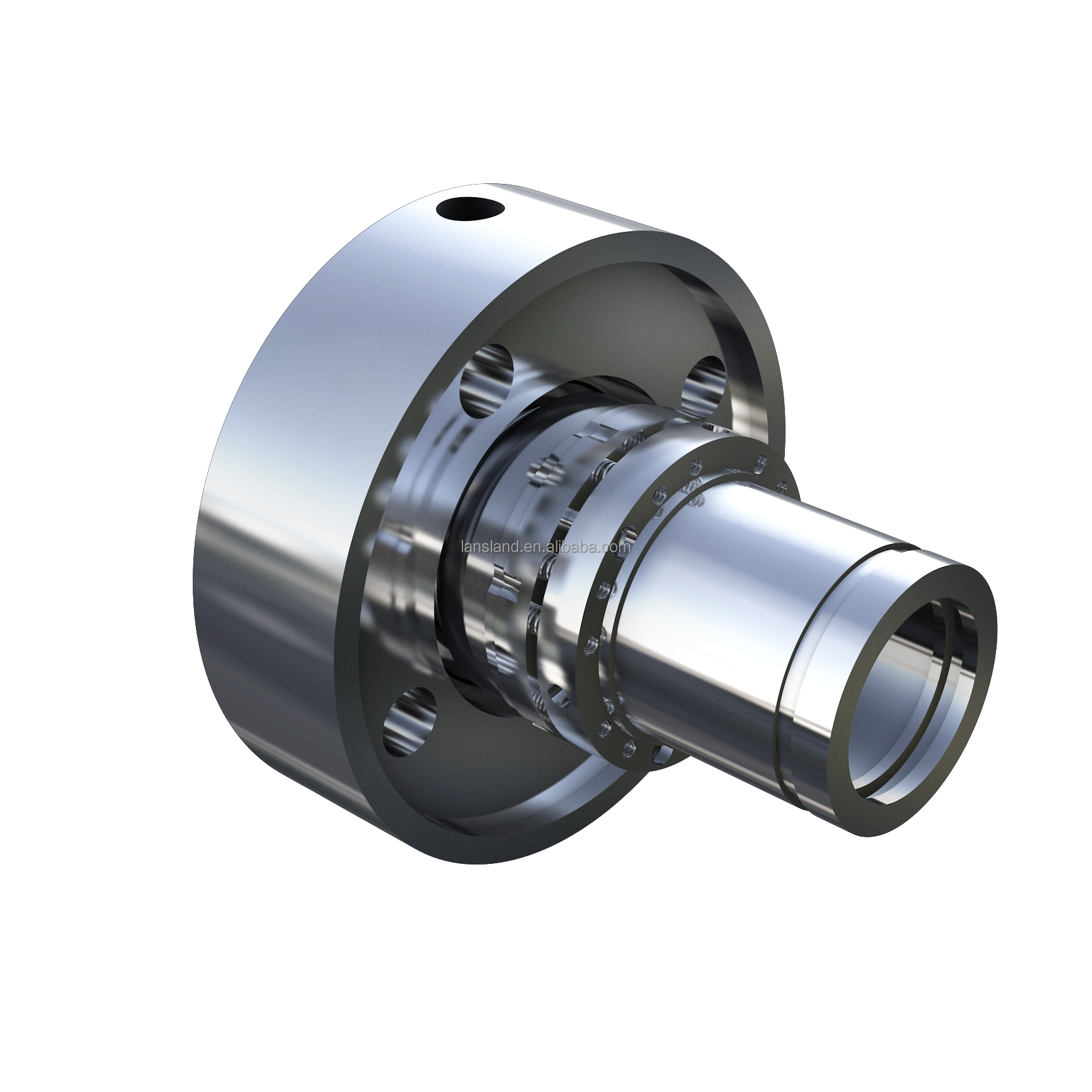

5. Standards:

API Std 682

JB/T 4127