- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

as per model

-

Weight:

-

1000 KG

-

Product name:

-

sand making machine price

-

Color:

-

Iron Grey

-

Installation:

-

Engineer Guide

-

After sale Service:

-

Maintenance

-

Processed Materials:

-

Granite, quartz, basalt, pebble

-

Keyword:

-

sand making machine price

-

Input Size:

-

0-50mm

-

Model:

-

sand making machine price

-

Spare parts supply:

-

12 Months Guarantee

-

Factory visit:

-

Weclcomed Warmly

Quick Details

-

Application:

-

mining quarry

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ZENITH

-

Dimension(L*W*H):

-

as per model

-

Weight:

-

1000 KG

-

Product name:

-

sand making machine price

-

Color:

-

Iron Grey

-

Installation:

-

Engineer Guide

-

After sale Service:

-

Maintenance

-

Processed Materials:

-

Granite, quartz, basalt, pebble

-

Keyword:

-

sand making machine price

-

Input Size:

-

0-50mm

-

Model:

-

sand making machine price

-

Spare parts supply:

-

12 Months Guarantee

-

Factory visit:

-

Weclcomed Warmly

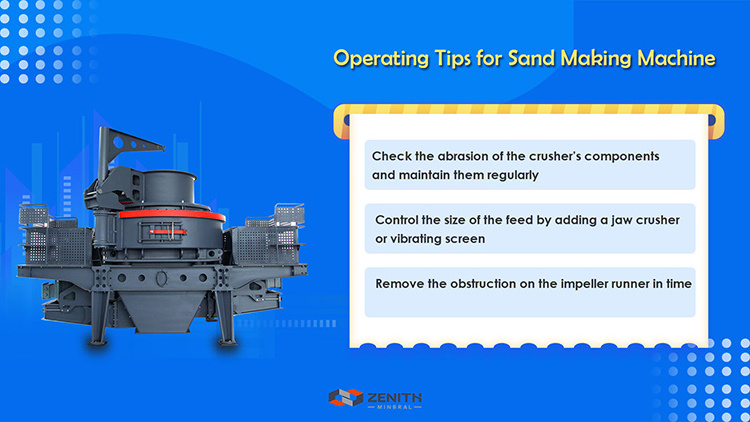

The sand making machine price, also known as sand maker or sand making machine, is designed for efficiently manufacturing artificial sand. By perfectly integrating the crushing chamber structure and high-speed centrifugal force, it produces sand particles with excellent grain shape.

The interior of the crusher is filled with steel balls in different specifications. Under high-speed rotation, the fast-moving steel balls continuously impact, grind, and squeeze the stone materials fed into the crushing chamber from the entrance side. Gradually, the stones are decomposed into sand grains with sharp edges and excellent regularity in shape.

The sand making machine price can crush various rocks, such as limestone, basalt, river pebbles, etc. into small sand particles efficiently. The finished sand is in accordance with national standards for construction aggregates, and its grain shape is excellent.

Thanks to high efficiency and large output, sand produced by this machine has stable grain shape and is suitable for concrete batching. It can effectively replace natural sand for better workability and impermeability of concrete.

sand making machine price working principle:

VSI5X Vertical-shaft sand making machine price (also known as “Sand Maker”) has two feed modes – “feed at center” and “feed at center & sides”. As for the former mode “feed at center”, materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode “feed at center & sides”, firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.

sand making machine price album:

sand making machine price parameters:

| Model | Soft material | Hard material | Side and central feeding | Fully central feeding | Speed (r/min) | Power (kw) | Overall dimension (mm) |

| Maximum feeding size (mm) | Throughput (t/h) | ||||||

| VSI5X1145 | 50 | 45 | 500-640 | 250-360 | 1100-1310 | 220×2 | 5000×2790×3320 |

| VSI5X9532 | 45 | 40 | 350-540 | 180-280 | 1300-1510 | 160×2 | 4560×2600×2900 |

| VSI5X8522 | 40 | 35 | 240-380 | 120-190 | 1500-1700 | 110×2 | 4140×2500×2700 |

| VSI5X7615 | 35 | 30 | 150-280 | 70-140 | 1700-1900 | 75×2 | 4100×2330×2300 |

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above 600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this website are for reference only. There is a chance that ZENITH may make changes on above-mentioned information. For specific messages, please refer to the real objects and user manuals. Without special instructions, ZENITH keeps the right to explain all data involved in this website.

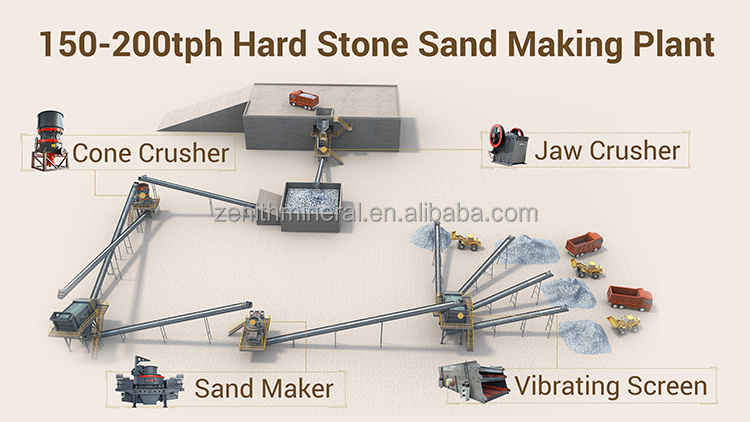

VIETNAM 250TPH DRY sand making machine price PLANT

DESIGN CRITERIA

• Material: Limestone

• Output Size: 0-3mm

• Type: Indoor Plant

• Environment Criteria: No-water System; Low-dust system

• Application: Highway construction and Brick Making

Conventional technology for making sand adapts water-washing system to remove the find powder from the sand, where the percentage of powder must be controlled below 7%. As a result, powder will be transformed into mud and going to waste and contamination.

By taking use of our grinder technology, ZENITH R&D team designs a new sand making system without using water. What`s more, powder can be recycled and reused.

PROJECT ADVANTAGES

Excellent Quality of Sand - Sand manufactured from ZENITH VSI is with good shape, and percentage of each size particle achieves the International Sand Standard. Furthermore, customer can adjust the percentage by taking use of our separator according to their actual demand.

Powder Recycled and Reused - The powder recycled from our new process can be reused in brick making plant, what`s more that the quality of brick improves.

Interchangeability - Excellent layout design allows customer to do modification. Actually, our smart customer adds one more screen to separate 10-20mm product from our impact crusher due to its superb shape. (Advantage of our impact crusher)