- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to Model

-

Weight:

-

According to Model

-

Item:

-

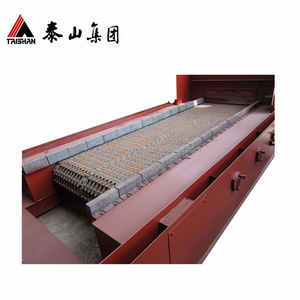

coal fired chain grate stoker/Vibrating grate/traveling grate boiler

-

Boiler Color:

-

Customize

-

Thermal Efficiency:

-

>80%

-

Rated Steam Pressure:

-

0.7MPa, 1.0MPa, 1.25MPa, 2.5MPa, 3.8MPa

-

Different model for steam boiler:

-

DZL, WNS, SZS, LNB, DZH

-

Drum Number:

-

Double Drums

-

Auxiliary Equipment:

-

Available

-

Boiler Installation:

-

Available

-

Boiler Warranty:

-

2 Years

-

Company Type:

-

Boiler Manufacture

-

Certification:

-

ISO9001:2008

Quick Details

-

Core Components:

-

boiler body

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YuanDa

-

Dimension(L*W*H):

-

According to Model

-

Weight:

-

According to Model

-

Item:

-

coal fired chain grate stoker/Vibrating grate/traveling grate boiler

-

Boiler Color:

-

Customize

-

Thermal Efficiency:

-

>80%

-

Rated Steam Pressure:

-

0.7MPa, 1.0MPa, 1.25MPa, 2.5MPa, 3.8MPa

-

Different model for steam boiler:

-

DZL, WNS, SZS, LNB, DZH

-

Drum Number:

-

Double Drums

-

Auxiliary Equipment:

-

Available

-

Boiler Installation:

-

Available

-

Boiler Warranty:

-

2 Years

-

Company Type:

-

Boiler Manufacture

-

Certification:

-

ISO9001:2008

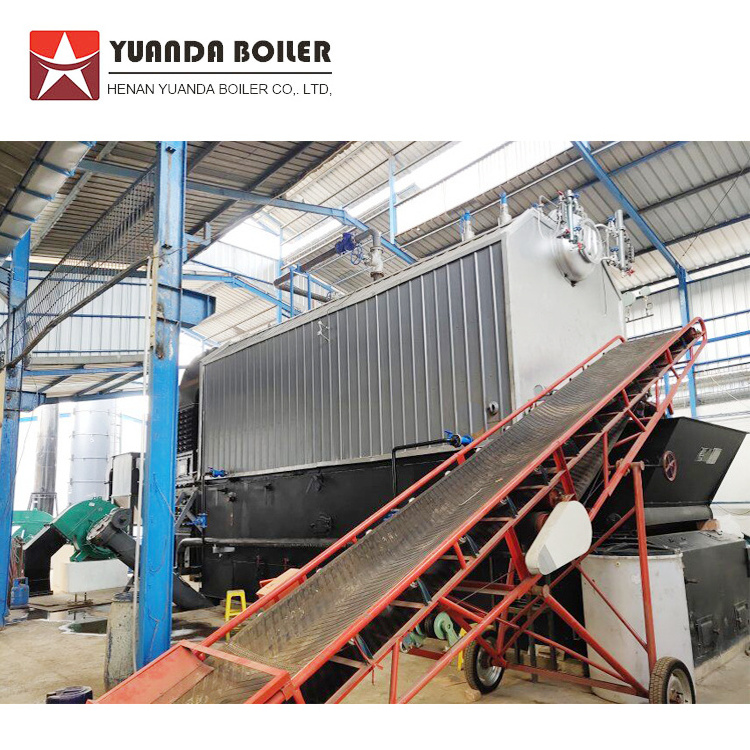

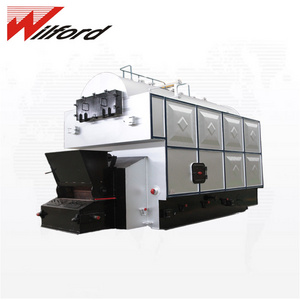

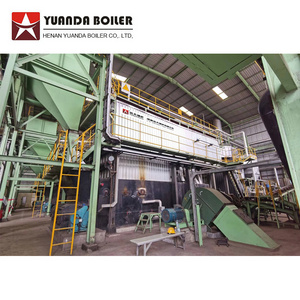

Best Selling coal fired chain grate stoker/Vibrating grate/traveling grate boiler

SZL series "A" type chain grate boiler

Our company SZL type boiler is a double-drum water tube assembly chain grate boiler (A type layout). The boiler proper has an upper drum and a bottom drum longitudinally arranged along the boiler center. The front of the upper drum and two sides water wall tubes constitute the boiler hearth radiation heating surface, and the tubes between the rear of the upper drum and the bottom drum constitute the convection heating surface. The economizer is arranged on the rear of the boiler,part of heat from high temperature exhaust gas generated by burning was absorbed by economizer, then the exhaust gas go through the cooling chamber,exhaust gas enters the convection heating surface to transfer heat power again, and through economizer,dust collector, finally draught by ID fan to Chimney,discharges into the atmosphere.

1.Model:SZL(A)

2.Capacity: 2 ton/h to 40 ton/h

3.Design pressure:1.0Mpa(10bar/10kg/145psi), 1.25Mpa(13bar/13kg/180psi), 1.6Mpa(16bar/16kg/232psi),2.5Mpa(25bar/25kg/362psi), other pressure need to be specially design.

4.Stem temperature:184℃,194 ℃,205℃,226℃, other temperature need to be specially design.

5.Design fuel:coal,biomass,palm oil shell,wood chips,biomass pellet,cashew nut, rice husk,solid fuel,etc

6.Structure: double drum water tube "A" type

| Boiler model | Rated capacity |

Rated pressure

|

Rated steam temp.

|

Feed water temp. | Exhaust gas temp. | Design effiency | Boiler water volume | Weight | Dimension | Delivery mode |

| ton/h | Mpa | ℃ | m2 | ℃ | % | m3 | ton | mm | ||

| SZL2 | 2 |

1.25/1.6/ 2.5/3.82 |

194/204/ 226/450 |

20/105 | 130.67 | 83.13 | 6.76 | 22 | 5900×2850×3460 | Package |

| SZL4 | 4 | 142 | 84.23 | 5.1 | 29 | 6460×3280×3462 | Package | |||

| SZL6 | 6 | 142 | 84.81 | 8.4 | 34 | 7830×3560×3462 | Package | |||

| SZL8 | 8 | 149.15 | 85.02 | 9.4 | 40.5 | 8870×3670×3462 | Package | |||

| SZL10 | 10 | 152.7 | 86.2 | 8.35 | 24 | 7645×3180×3526 | Assembly | |||

| SZL12 | 12 | 148.7 | 86.56 | 12.8 | 37 | 9258×3294×3524 | Assembly | |||

| SZL15 | 15 | 149.86 | 86.29 | 15.5 | 24.7 | 11010×3300×2200 | Assembly | |||

| SZL20 | 20 | 147.4 | 86.8 | 15.8 | 25.97 | 16680×6200×8420 | Assembly | |||

| SZL25 | 25 | 149.6 | 86.4 | 16.5 | 28 | 8300 ×3000×3600 | Semi-Assembly | |||

| SZL30 | 30 | 148.6 | 86.8 | 16.8 | 29 | 8500 ×3600×3640 | Semi-Assembly | |||

|

Notice: 1.special proposal is available according to different place's different encironmental requirements; 2. burning fuel's heat value/chemincal component different, parameter different; 3.Since the boiler technology is keep updating, if there is any update in the future, no special imform. |

||||||||||

Pre-sale service:

We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

After-sale service:

1.provide full range of original spare parts.

2.Engineers abroad installation and commissioning service is available.

3.Our engineers will held a training for boiler workers to ensure the safe operation.

4.Free maintenance and repair for one year and lifelong service.