Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

YAQI-CP001

-

Material:

-

PP+PE

-

Pile Height:

-

10mm/15mm/20mm/25mm/30mm/40mm/50mm

-

Stitches/m:

-

110/150/180/200 turfs

-

Gauge:

-

3/8 Inch

-

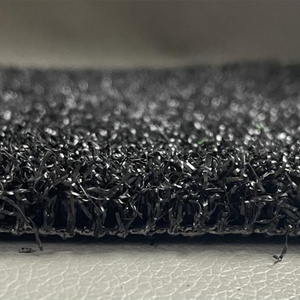

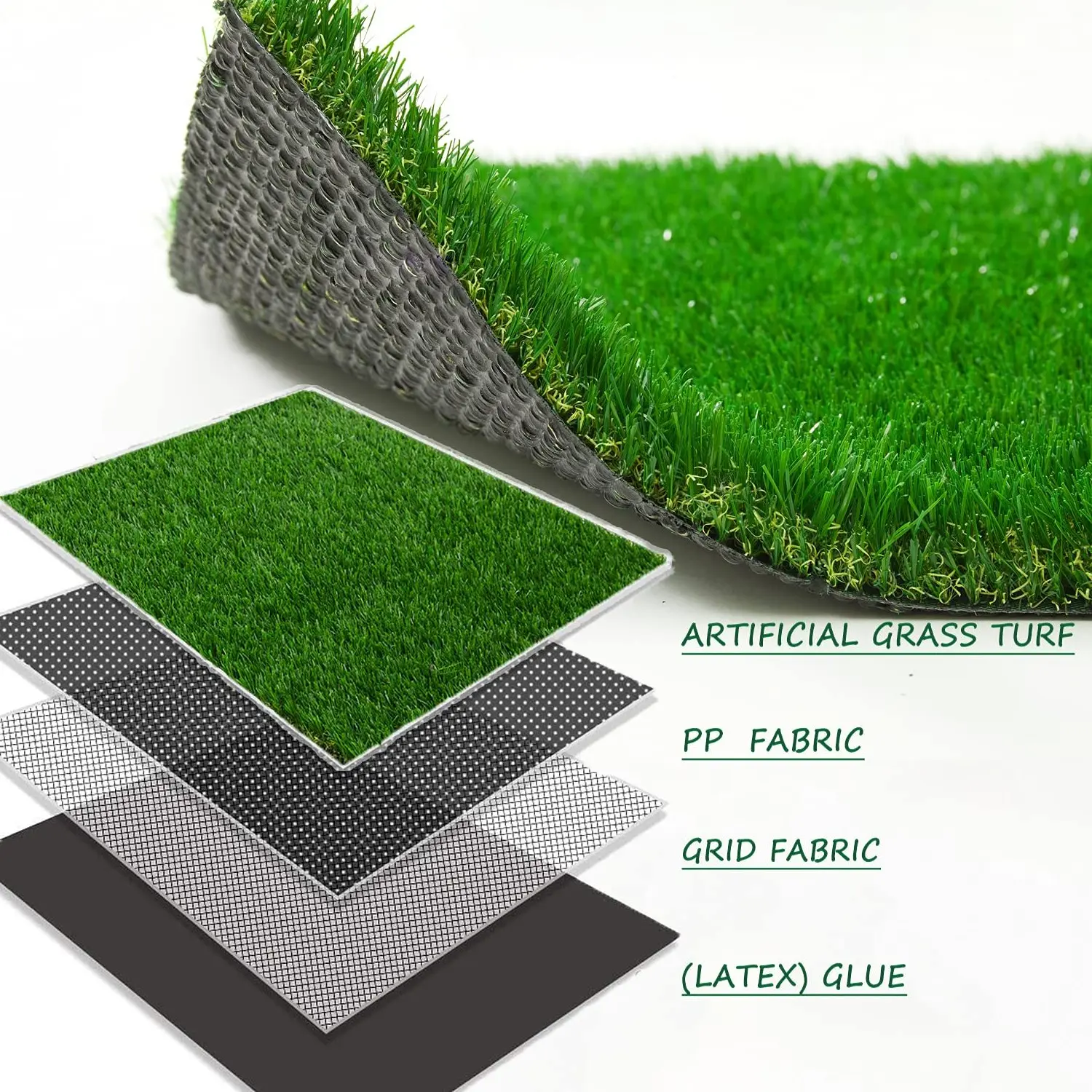

Backing:

-

PP fabric + Grid + SBR Latex(3 layers)

-

Application:

-

Football Field, Golf, Residential Landscaping

-

Package:

-

Paper tubes; Packed with PP Fabric

-

Warranty:

-

5~8 Years

-

Size:

-

2*25/4*25 Customized Size

Quick Details

-

Color:

-

Green, Apple Green+Light Green or customized

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YAQI

-

Model Number:

-

YAQI-CP001

-

Material:

-

PP+PE

-

Pile Height:

-

10mm/15mm/20mm/25mm/30mm/40mm/50mm

-

Stitches/m:

-

110/150/180/200 turfs

-

Gauge:

-

3/8 Inch

-

Backing:

-

PP fabric + Grid + SBR Latex(3 layers)

-

Application:

-

Football Field, Golf, Residential Landscaping

-

Package:

-

Paper tubes; Packed with PP Fabric

-

Warranty:

-

5~8 Years

-

Size:

-

2*25/4*25 Customized Size

Products Description

Artificial grass is made of high polymer fiber yarns that look like real grass. Synthetic turf is mainly composed of grass fibers, bottom backing and coating. The artificial turf field is a system consisting of base, synthetic grass, infill and, in some special fields, shock pad at the bottom of the turf to meet the needs of sports.

Products details

Material

What is grass made out of ? At first, artificial grass was made from nylon (PA), then polypropylene (PP), and now mainly polyethylene (PE).The most common polymer used is a grade known as C4, but more advanced artificial grass manufacturers use C8, a purer and stronger material. This is more expensive but helps to produce longer lasting yarns.

Fibrillated or monofilament

Whilst using the same raw materials, after the melting and mixing part, two different but similar production routes are followed.Fibrillated yarn is created as a tape, which has a perforation pattern added, that allows fibers to open up on tufting, to create the grass-like appearance.

Understanding the Basics of Blade Shapes

Artificial grass blade shapes play a vital role in determining how your lawn looks, feels, and performs. Each shape has unique properties that influence the overall aesthetics and functionality of your turf.

Product specification

|

Material:

|

PP+PE

|

|

|

|

|||

|

Pile Height:

|

10mm/15mm/20mm/25mm/30mm/40mm/50mm

|

|

|

|

|||

|

Stitches:

|

110/150/180/200 turfs per meter or customized

|

|

|

|

|||

|

Backing:

|

PP fabric + Grid + SBR Latex(3 layers)

|

|

|

|

|||

|

Backing Color:

|

Normal Black, Green and Purple are available

|

|

|

|

|||

|

Roll Width:

|

2M or 4M

|

|

|

|

|||

|

Roll Length:

|

25M or upon request, not over 100M

|

|

|

|

|||

|

Color Fastness:

|

Over 8 years

|

|

|

|

|||

|

UV Resistance:

|

Normally 3% or 5%

|

|

|

|

|||

|

Applications:

|

Football Field, Golf, Garden, Balcony,Roof,Kindergarten, Residential Landscaping

|

|

|

|

|||

|

Delivery Time:

|

3-15 days

|

|

|

|

|||

|

Package:

|

Roll up with paper tubes inside; Packed with PP Fabric outside

|

|

|

|

|||

Production Process

Yarn Production Process of Artificial Grass Manufacturing

The process to produce the fiber that is used in artificial grass is called extrusion. In very simple terms raw polymer pellets, colour and UV additives are mixed together, then transformed into either a tape or individual fibers. These are then twisted and wound onto spools that are then sent to the next stage of the artificial grass manufacturing process.

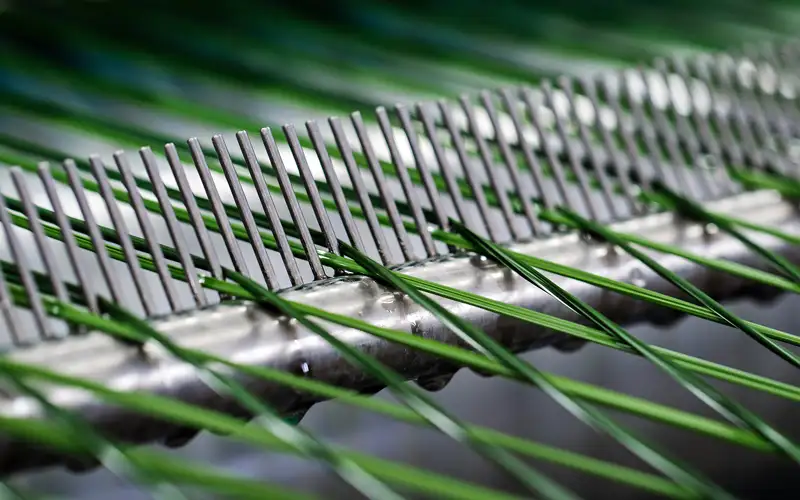

Turf Production Process – Tufting of Artificial Grass Manufacturing

The process of artificial grass manufacturing whereby fiber is tufted into a backing cloth, then cut to create individual tufts of synthetic grass.

Turf Production Process – Backing of Artificial Grass Manufacturing

1.

This process ensures that the fibers are secured to create the finished synthetic turf, thereby completing the artificial grass manufacturing process.

2

.

Drainage

As the, now backed, turf leaves the ovens it passes into an area where drainage holes are punched through the turf, at an equal distance, to ensure future, rapid drainage. From here the turf is suspended into collecting bins, ready for final inspection.

As the, now backed, turf leaves the ovens it passes into an area where drainage holes are punched through the turf, at an equal distance, to ensure future, rapid drainage. From here the turf is suspended into collecting bins, ready for final inspection.

Installation

Step 1: Clean existing concrete

Begin by thoroughly cleaning the concrete surface of any debris, chemicals, dirt, mold, or residue. You can hose down the concrete and scrub it with a stiff broom. Allow the surface to dry, ensuring that any chemicals from cleaning agents completely dissipate before moving on to the next step.

Begin by thoroughly cleaning the concrete surface of any debris, chemicals, dirt, mold, or residue. You can hose down the concrete and scrub it with a stiff broom. Allow the surface to dry, ensuring that any chemicals from cleaning agents completely dissipate before moving on to the next step.

Step 2: Install drainage tiles if necessary

Cleaning the concrete or pavement is also an excellent opportunity to evaluate its drainage capabilities. If water dissipates without forming puddles, you can proceed to the next step. If not, consider installing drainage tiles between the concrete and the artificial grass to improve drainage and air circulation. Standing water may lead to mold issues beneath the grass, affecting the backing. It could also result in large puddles on the grass, rendering it unusable until the water drains or is removed.

Cleaning the concrete or pavement is also an excellent opportunity to evaluate its drainage capabilities. If water dissipates without forming puddles, you can proceed to the next step. If not, consider installing drainage tiles between the concrete and the artificial grass to improve drainage and air circulation. Standing water may lead to mold issues beneath the grass, affecting the backing. It could also result in large puddles on the grass, rendering it unusable until the water drains or is removed.

Step 3: Lay shock pads (optional)

While synthetic grass can be placed directly on concrete, some prefer an additional cushion of padding. Artificial turf provides traction and some cushioning for walking, but for those seeking heightened comfort, think about incorporating shock pads. This choice impacts cost, installation time, and the final look—it’s a personal preference, not a necessity.

While synthetic grass can be placed directly on concrete, some prefer an additional cushion of padding. Artificial turf provides traction and some cushioning for walking, but for those seeking heightened comfort, think about incorporating shock pads. This choice impacts cost, installation time, and the final look—it’s a personal preference, not a necessity.

Step 4: Prep & install the turf

Unroll the artificial grass and let it sit in sunlight for at least an hour to smooth out creases. Cut it to the desired

dimensions, trimming edges from the back to avoid cutting through the stitches. If there are seams, ensure the fibers face the same direction. Trim 3 stitches on each side to ensure a seamless joint. Place tape along the underside of the seam, applying pressure to bond them securely.

Unroll the artificial grass and let it sit in sunlight for at least an hour to smooth out creases. Cut it to the desired

dimensions, trimming edges from the back to avoid cutting through the stitches. If there are seams, ensure the fibers face the same direction. Trim 3 stitches on each side to ensure a seamless joint. Place tape along the underside of the seam, applying pressure to bond them securely.

Step 5: Secure the perimeter with glue

Trim excess turf along the concrete edge using a utility knife. Fold back the grass edges, applying glue around the entire perimeter. Allow a few hours for proper bonding; avoid walking on the grass during this time to prevent any shifting.

Trim excess turf along the concrete edge using a utility knife. Fold back the grass edges, applying glue around the entire perimeter. Allow a few hours for proper bonding; avoid walking on the grass during this time to prevent any shifting.

Step 6: Apply silica sand & brush the grass

After the glue dries, move on to the final step. Applying silica sand infill offers a range of benefits, including stabilizing the turf to prevent wrinkles, boosting durability, and maintaining the fibers in an upright position for a more appealing look. Evenly distribute the infill and then use a rake or grass brush to groom the lawn.

After the glue dries, move on to the final step. Applying silica sand infill offers a range of benefits, including stabilizing the turf to prevent wrinkles, boosting durability, and maintaining the fibers in an upright position for a more appealing look. Evenly distribute the infill and then use a rake or grass brush to groom the lawn.

Application

Package and shipping

Hot Searches