- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongjin

-

Model Number:

-

HY-TH-100DH

-

Product name:

-

Climate Test Machine

-

Heating time:

-

3°C/min

-

cooling time:

-

1°C /min

-

Power supply:

-

AC220V 50/60Hz & 1

-

Heating/cooling time:

-

Warming up about 4.0°C/min

-

Brand:

-

HONGJIN

-

Other Power supply:

-

AC380V 50/60Hz&3

-

Temperature range:

-

A: +25 °CB: 0°C, C: -20°C, D: -40°C, E: -60°C, F: -70°C)

-

Humidity range:

-

20%~98% R.H.

-

Control accuracy:

-

±0.5°C, ±2.5%R.H.

Quick Details

-

Warranty:

-

12 MONTHS

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Hongjin

-

Model Number:

-

HY-TH-100DH

-

Product name:

-

Climate Test Machine

-

Heating time:

-

3°C/min

-

cooling time:

-

1°C /min

-

Power supply:

-

AC220V 50/60Hz & 1

-

Heating/cooling time:

-

Warming up about 4.0°C/min

-

Brand:

-

HONGJIN

-

Other Power supply:

-

AC380V 50/60Hz&3

-

Temperature range:

-

A: +25 °CB: 0°C, C: -20°C, D: -40°C, E: -60°C, F: -70°C)

-

Humidity range:

-

20%~98% R.H.

-

Control accuracy:

-

±0.5°C, ±2.5%R.H.

Product Description

Product Usage

The simulated products are tested under the combination of temperature and humidity in the climatic environment (high

and low temperature operation & storage, temperature cycle, high temperature and high humidity, low temperature and low humidity,condensation test, etc.) to check whether the adaptability and characteristics of the product itself change.

and low temperature operation & storage, temperature cycle, high temperature and high humidity, low temperature and low humidity,condensation test, etc.) to check whether the adaptability and characteristics of the product itself change.

Test limit

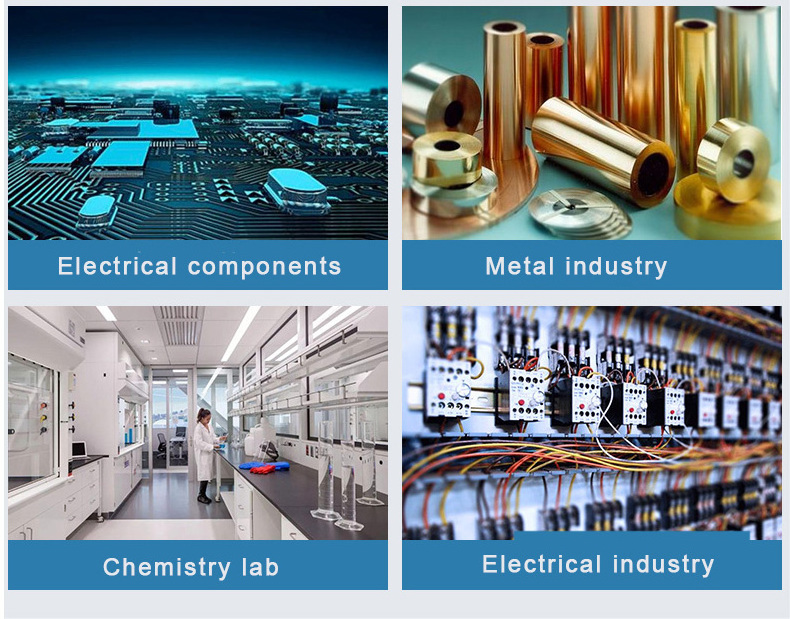

This test equipment is suitable for:

This test equipment is suitable for:

Electrical, electronic products, components and materials are stored in high and low

temperature environments Adaptability tests for storage, transportation and use.

Use of this test equipment is prohibited:

1.Testing or storage of flammable, explosive, volatile materials

temperature environments Adaptability tests for storage, transportation and use.

Use of this test equipment is prohibited:

1.Testing or storage of flammable, explosive, volatile materials

2.Testing or storage of samples of corrosive substances

3.Testing or storage of biological samples

4.Testing or storage of samples from sources of strong electromagnetic radiation

The test standard to which the machine meets

ASTM F2825:Standard Specification for Climate Stress of Single-Package Shipping Packaging Systems

ASTM D6944:Standard Practice for Determining Thermal Cycling Resistance of Cured Coatings

ASTM D2126:Standard Test Method for Heat and Moisture Aging Response of Rigid Foams

MIL-STD-810G:High and low temperature testing part;Damp heat testing part

MIL-STD-202F: High and low temperature testing part;Damp heat testing part

ASTM D2126:Standard Test Method for Heat and Moisture Aging Response of Rigid Foams

MIL-STD-810G:High and low temperature testing part;Damp heat testing part

MIL-STD-202F: High and low temperature testing part;Damp heat testing part

|

Model

|

TH-80(A~F)

|

TH-150(A~ F)

|

TH-225(A~F)

|

TH-408(A~F)

|

TH-800(A~ F)

|

TH-1000(A~F)

|

|

Internal size W x H x D(cm)

|

40x50x40

|

50 x 60 x 50

|

60 x 75 x 50

|

80 x 85 x60

|

100x100x80

|

100x100x100

|

|

External dimensions W x H x D(cm)

|

120x165x115

|

130x170x125

|

140x185x130

|

165x195x155

|

185x200x175

|

190x210x185

|

|

Weight (approximately)

|

150KG

|

180KG

|

250KG

|

350KG

|

500KG

|

520KG

|

|

Temperature range

|

Low temperature: A: +25 °CB: 0°C, C: -20°C, D: -40°C, E: -60°C, F: -70°C) High temperature: 100°C (150°C )

|

|

Humidity range

|

20%~98% R.H. (10%~98%R.H); (5%~98%R.H is a special selection condition)

|

|

Temperature and humidity analysis accuracy/distribution accuracy

|

0.1°C 0.1%R.H./±2.0℃ ±3.0%R.H.

|

|

Temperature and humidity control accuracy

|

±0.5°C, ±2.5%R.H.

|

|

Heating/cooling time

|

Warming up about 4.0°C/min; cooling down about 1.0°C/min

|

|

Internal and external materials

|

The inner and outer boxes are made of SUS304# stainless steel plate (baking paint is optional)

|

|

Insulation material

|

High temperature resistant high density ethyl chloroformate foam insulator material

|

|

Cooling system

|

Air-cooled/single-stage compressor (-20°C); two-stage compressor (-40°C-70°C)

|

|

Safety protection device

|

Fuseless switch, compressor overload protection, refrigerant high and low pressure protection, ultra-humidity and over-temperature

protection, fuse, fault warning system, water shortage alarm protection |

|

Accessories

|

Operation hole built-in glass door (optional), recorder (optional), viewing window, 50mm test hole, PL box light, partition, dry

and wet ball gauze, casters, horizontal tripod |

|

Power supply

|

AC220V50/60Hz & 1∮ AC380V50/60Hz3∮

|

Structure

1.Thermal insulation structure

(can be customizable)

Outer wall material: high quality stainless steel 304 / cold rolled steel plate painting Inner wall material: high quality stainless steel 304 Box insulation material: flame retardant fireproof rigid polyurethane foam Door insulation material: flame retardant fireproof rigid polyurethane foam. 2.Air conditioning channel Centrifugal fan, return air mode: air blow on equipment, return air Heater, evaporator, water supply and drain, temperature sensor. 3.Test box standard configuration

(can be customizable)

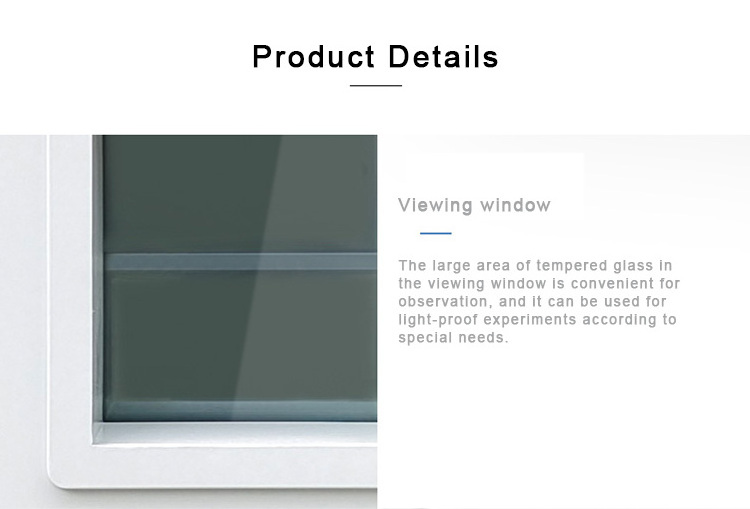

Window 250x320x40mm 3-layer vacuum layer Explosive handle Door hinge: SUS #304 Box light PL light 11W Lead hole: φ50mm 1 4.Door

(can be customizable)

Single door, left open, handle on the right hand side. With observation window 250*320 mm, lighting, Window frame/door frame anti-condensation electric heating device 5. Control panel Controller display, over temperature protection setter 6. Mechanical room Refrigeration unit, water tray, drain hole 7. Distribution control cabinet, distribution board, exhaust fan 8. Heater Heating system: finned heat pipe type stainless steel electric heater heating air circulation mode 9. Humidifier Boiler type humidification system, circulating through the air duct system. 10. Power cable hole and drain hole are located on the back of the cabinet

Cooling System

1.Condenser Water-cooled shell tube heat exchanger. 2. Expansion system Refrigeration system (capillary) for capacity control. 3. Evaporation condenser Stainless steel brazed plate heat exchanger. 4. Refrigerator control mode The controller of the control system automatically adjusts the operating conditions of the refrigerator according to the test conditions. Evaporate the pressure regulating valve. Compressor return air cooling circuit. 5. Temperature and humidity controller It adopts the micro-computer color LCD display touch screen, Chinese wide angle of view, high contrast function temperature and humidity can be programmed at the same time, with 100 groups of programs 1000 segments of memory, each segment 530Hour59Min, can be arbitrarily divided Settings, and With multiple sets of PID control functions. 6. Controller Specifications Accuracy: temperature ±0.1 °C+1 digit, humidity ±1% R.H+1digit Resolution: temperature ± 0.01 ° C, humidity ± 0.1% R. H. Temperature slope: 0.1 ~ 9.9 can be set. With upper and lower limit standby and alarm function. Temperature and humidity input signal dry and wet ball PT100x2. 7 sets of P.I.D control parameter settings, P.I.D automatic calculation. Dry and wet balls are automatically corrected.

Safety device

Cooling System

Compressor overheating Compressor overcurrent Compressor overpressure Condensing fan overheating Compressor oil pressure protection

Installation site

The floor is flat and well ventilated No strong vibration around the device No strong electromagnetic field around the device No flammable, explosive, corrosive substances and dust around the equipment.Appropriate use and maintenance space is left around the equipment

As shown left

A: not less than 10cm B: not less than 60cm C: not less than 60cm D: not less than 120cm

Feture at a glance

Product show

Hot Searches