- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Voltage:

-

380V

-

Weight:

-

1.8 KG

-

Dimension(L*W*H):

-

2250*1450*1400mm

-

Type:

-

180 Briquette Machines

-

Production Capacity:

-

1-6T/h

-

Product name:

-

briquette extruder machine

-

Applicable raw materials:

-

charcoal powder, coal dust.

-

Raw material size:

-

less than 5mm

-

Finished shape:

-

Square, hexagonal,round

-

Moisture of material:

-

less than 25%

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Colour:

-

According to customer's demand

-

Power:

-

15-37KW

Quick Details

-

Warranty:

-

2 years

-

Core Components:

-

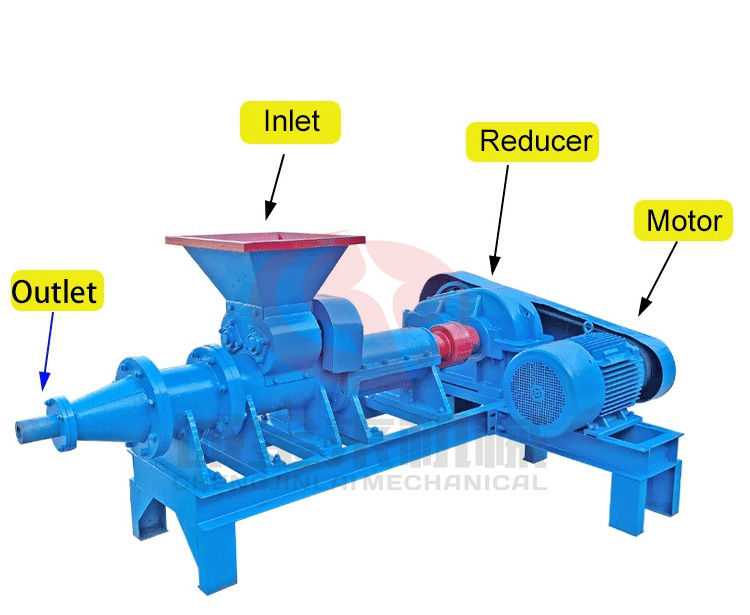

PLC, Bearing, Gear, Motor, Thruster, Forming cylinder, Heating coil, Reducer, Spiral blade

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

CHENG JINLAI MECHANICAL

-

Voltage:

-

380V

-

Weight:

-

1.8 KG

-

Dimension(L*W*H):

-

2250*1450*1400mm

-

Type:

-

180 Briquette Machines

-

Production Capacity:

-

1-6T/h

-

Product name:

-

briquette extruder machine

-

Applicable raw materials:

-

charcoal powder, coal dust.

-

Raw material size:

-

less than 5mm

-

Finished shape:

-

Square, hexagonal,round

-

Moisture of material:

-

less than 25%

-

aftersale service provided:

-

Engineers available to service machinery overseas

-

Colour:

-

According to customer's demand

-

Power:

-

15-37KW

|

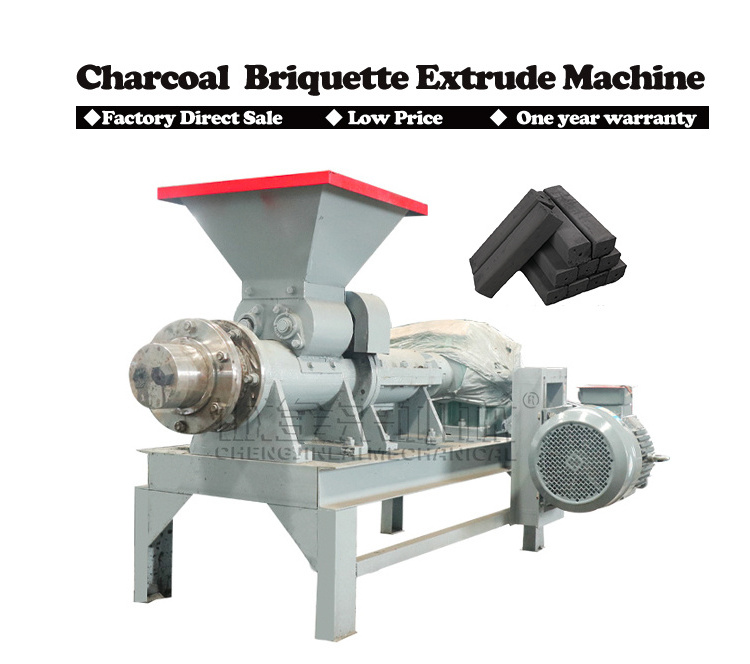

Charcoal coal making equipment BBQ charcoal making machine charcoal pulverized coal briquetting machine

|

|

|

|

|

||||

Product Description

Charcoal coal making equipment BBQ charcoal making machine charcoal pulverized coal briquetting machine

can make coal and charcoal powder into sticks.

It is suitable for charcoal powder, wood charcoal powder, coconut shell charcoal powder, rice husk charcoal powder, charcoal dust, coal powder.

Workng Principle of the charcoal briquette machine:

This machine feed the ratio and retting coal powder mixture into a nitrogentreated barrel by the extrusion of principle, which will compress into section for round or plum flower form or other shape. The fianl coal rods have a certain mechanical strength by formed in this equipments.

Machine Real Shot

Automatic cut-off device

Roller Cutter

Specification

|

Model

|

CM140

|

CM160

|

CM180

|

|

Capacity

|

1-1.5t/h

|

1.5-2t/h

|

2-3t/h

|

|

Power

|

15kw

|

22kw

|

22kw-30kw

|

|

Feeding size

|

≤5mm

|

≤5mm

|

≤5mm

|

|

Moisture content

|

25%-35%

|

25%-35%

|

25%-35%

|

Raw materials&final products

Molds

Sample Real Shot

Process flow

1. If you raw material is sawdust or rice husk or coconut shell.use our

carbonization stove

to carbonize your raw material into charcoal.

2. The seond step:Use

crusher

to grind charcoal into powder

3. Then use the

Charcoal mixer

to mix the charcoal powder with binder.

4. Put the starch and water into

binder mixer

, then mix them.

5. The final step:use our briquette machine to produce many different shapes briqette base on you need.

Other charcoal forming equipment is also available for you to choose!

Customer site

Packing & Delivery

Hot Searches