- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600mm*1200mm*1800mm

-

Motor Power (Kw):

-

132KW

-

Power (kW):

-

132KW

-

Weight (KG):

-

6500 KG

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-4000 kg/h

-

Pellet size:

-

6-12mm Diameter

-

After-sales Service Provided:

-

Commissioning

-

Advantage:

-

High Output

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

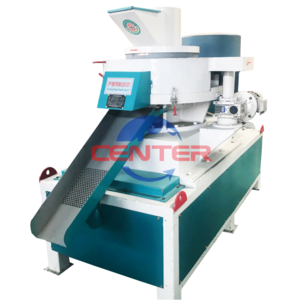

Wood Sawdust Pellet Biomass Wood Pellet Mill

-

Color:

-

Customer's Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

80 - 4000 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KX-MACHINERY

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

2600mm*1200mm*1800mm

-

Motor Power (Kw):

-

132KW

-

Power (kW):

-

132KW

-

Weight (KG):

-

6500 KG

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Make Biomass Fuel Pellets

-

Raw material:

-

Sawdust\straw\rice Husk\wood Waste

-

Capacity:

-

80-4000 kg/h

-

Pellet size:

-

6-12mm Diameter

-

After-sales Service Provided:

-

Commissioning

-

Advantage:

-

High Output

-

Length of Wood Pellets:

-

Adjustable Pellet Machine

-

Product name:

-

Wood Sawdust Pellet Biomass Wood Pellet Mill

-

Color:

-

Customer's Request

-

Machine type:

-

Biomass Fuel Wood Pellet Machine

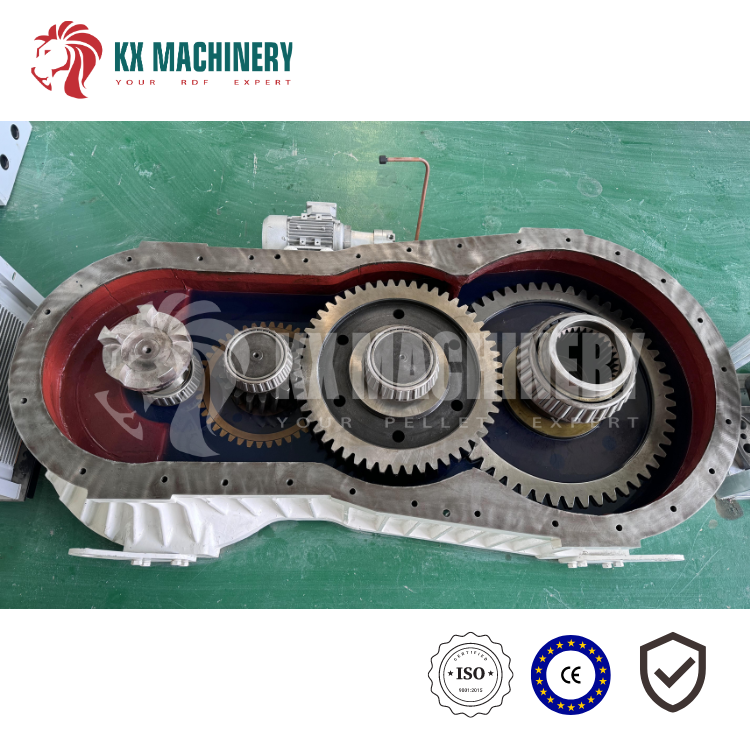

Transforming Timber into Tomorrow:

Powering Progress with Wood Pellet Magic!

|

Model

|

Main Motor

|

Capacity

|

Die diameter

|

Weight

|

|

VRD560A

|

90KW

|

1000-2000KG/H

|

560MM

|

5.5Ton

|

|

VRD560B

|

110KW

|

1200-1500KG/H

|

560MM

|

5.5Ton

|

|

VRD580

|

132KW

|

1500-2000KG/H

|

580MM

|

6.5Ton

|

|

VRD760

|

185KW

|

2000-30000KG/H

|

700MM

|

8.5Ton

|

|

VRD850A

|

220KW

|

3000-3500KG/H

|

850MM

|

14.5Ton

|

|

VRD850B

|

250KW

|

30000-4000KG/H

|

850MM

|

14.5Ton

|

1.Q: How do I know which size of vertical ring die pellet machine is suitable for my needs?

A: At our company, we understand the importance of matching the right machine to your requirements. Our team of experts will carefully assess your production needs, raw material characteristics, and output goals to recommend the most suitable pellet machine size for you.

2.Q: What kind of after-sales support do you offer?

A: We take pride in our comprehensive after-sales service. From installation guidance to troubleshooting and maintenance tips, our dedicated support team is always available to assist you. We prioritize customer satisfaction and are committed to ensuring that your pellet machine operates smoothly throughout its lifespan.

3.Q: Can I expect reliable performance and longevity from your vertical ring die pellet machines?

A: Absolutely. With over 20 years of experience in the industry, we have honed our craft to deliver top-quality machines built to withstand the rigors of continuous operation. Our vertical ring die pellet machines are engineered with precision and constructed using high-quality materials, ensuring both reliability and longevity for years to come.

4.Q: Can I expect reliable performance from your pellet machines?

A: Absolutely. With over two decades of experience in manufacturing pellet machines, we prioritize quality and reliability in every aspect of our production process. Our machines are built to withstand rigorous use and deliver consistent performance over their lifespan.

5.Q: How do you ensure the quality of your pellet machines?

A: Quality is our top priority. We source only the finest materials and components for our machines and subject them to rigorous quality control measures throughout the manufacturing process. Additionally, our commitment to continuous improvement ensures that our pellet machines meet the highest standards of excellence

6.Q: Do you provide training for operating the pellet machines?

A: Yes, we offer comprehensive training programs to ensure that you and your team are proficient in operating and maintaining our pellet machines. Our goal is to empower you with the knowledge and skills necessary to maximize the performance and longevity of your equipment.

Hot Searches