- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

10000X2400X3500mm

-

Certification:

-

CE

-

Power:

-

150 KW

-

Weight:

-

13 Mts

-

Type:

-

OTR tire retreading machine

-

MATERIAL:

-

Carbon Steel Q345R

-

Tire Size:

-

25'',33'',49'',51''

-

Heating Method:

-

Electric

-

Control Type:

-

Automatic Control

-

Color:

-

Yellow or Blue

-

Air Supply:

-

0.8 Mpa

-

Training:

-

Free

-

Installing:

-

Available

-

Contanier:

-

40 FR

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MELION

-

Model Number:

-

ML-OTR

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

10000X2400X3500mm

-

Certification:

-

CE

-

Power:

-

150 KW

-

Weight:

-

13 Mts

-

Type:

-

OTR tire retreading machine

-

MATERIAL:

-

Carbon Steel Q345R

-

Tire Size:

-

25'',33'',49'',51''

-

Heating Method:

-

Electric

-

Control Type:

-

Automatic Control

-

Color:

-

Yellow or Blue

-

Air Supply:

-

0.8 Mpa

-

Training:

-

Free

-

Installing:

-

Available

-

Contanier:

-

40 FR

OTR Tire Buffing Building Retread Machines

1-Giant OTR Tire Curing Chamber / Autoclave

Description

The tyres are placed in this Curing Chamber and the Pre-cured Tread becomes adhered to the tyre through a vulcanizing process.

Parameters

Model:DN35-4A.4

Insulation layer: rock wool

Control Mode: Semi- automatic

Heating Mode:Indirect heating

Energy Source:Electric

Design Pressure:6.5Bar

Material:Carbon steel

Design Temperature:180ºC

Inner diameter(mm):3500

Working length(mm):4000

Tank Wall Thickness(mm):14

Over All Size(mm):5200*3900*4200

Suitable for sizes:18.00 X 25 to 27.00 X 49 ,45/65 X 45

Functions

1. Vulcanization process is automatic controlled

2. Quadruple safety interlocks is adopted by the door of the autoclave

3. Automatic control and manual operation control system is equipped

4. Multifunctional system controls temperature, pressure, time

5.Tyre Rail-Car equiped for easy transporting

6. High temperature silicone seal is used by the vessel door

7. Insulation:All insulation material are used with high quality materials,and cylindrical body is covered with stainless steel material which prevents the formation of cracks and rustiness and assures the reliabitlity of the insulation itself.

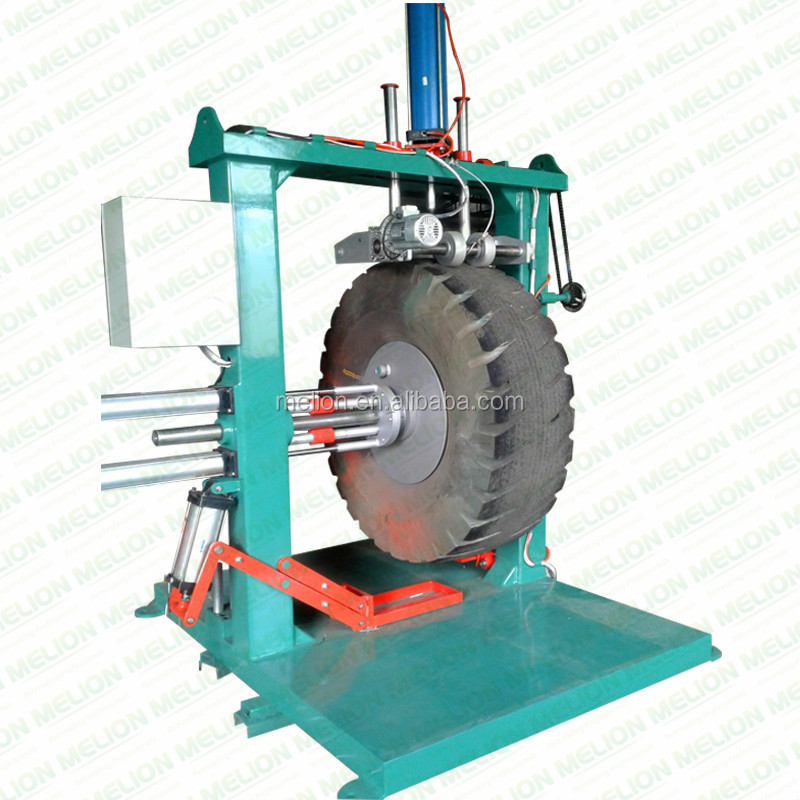

2.OTR Buffing Machine

Description

The tyre's old tread is mechanically removed on high speed buffers.

Parameters

Suitable Tyre Sizes: 25", 33", 35", 39", 45" and 49"

Buffing Head Speed:2980 r/min

Powered by 18.5kw

Chuck wheel speed:42 r/min

Total Power:35KW

External Dimensions(LWH):=3700×3300×3000 mm

Weight:5200kgs

Inflating:1.5Bar

Functions

1.Manual Buffing Device for sidewall and shoulder buffing

2.Easy loading and unloading of tyres

3.Over-Inflating protection function engineered

4.Buffer Head air-Cooler incase of high temperature burning

5.Equiped with Dust Collector for collecting rubber granules

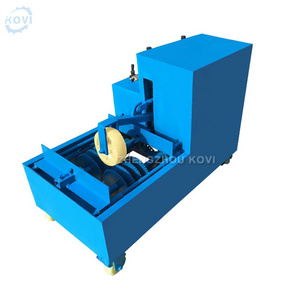

3.OTR Building Machine

Description

After Buffing the Tyre Casing needs a thin layer of Cushion Gum to be wrapped around its crown area.

Parameters

Suitable Tyre Sizes: 25", 33", 35", 39", 45" and 49"

Total power:9kw

External Dimensions (L×W×H):3500×3300×3500(mm)

Weight:4500kg

Functions

1.Over-Inflating protection function engineered

2.Easy loading and unloading of tyres

3.One big tread Roller and two side-rollers engineered

4.ENVELOPE SPREADER

Description

8pcs unsharp-angled hand grip well-proportioned distribute on the circle,protect the envelope and increase of service life.

Functions

The power of lifting and expanding by air cylinder, save the labor force and engergy.

For double-enveloping, tyres are first fitted an outer envelope at the envelope-mounting table before the inner envelope is fitted into them.

The enveloped tyres are then vacuumed out for preparation prior to curing.

Type

Vertical

5.others

As a tire retreading machines specialized manufacturing supplier who providing Turn-Key Service, Rizhao Melion Industry company provides customers with complete solutions all the time,including professional marketing planning,production line procedure analysis,suitable raw materials supply,free technical training and so on.

|

Complete Tire Retreading Solutions Supply *Full Set Tire Retreading Equipment *Precured Tread Rubber materials *Cushion Gum *Retreading Accessories and Tools |

Melion Team Technical Support

*Factory Layout

|