- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZW

-

Voltage:

-

220V/380V/450V/as your requirement

-

Dimension(L*W*H):

-

900*900*930mm

-

Weight:

-

180 KG

-

Product name:

-

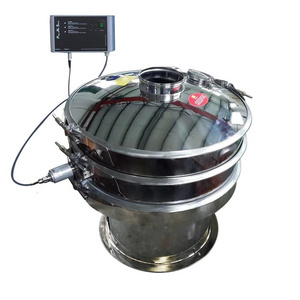

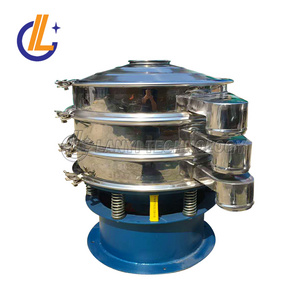

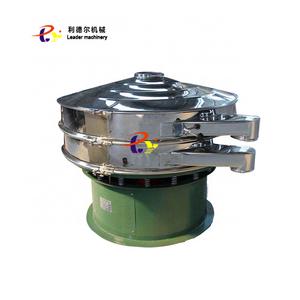

Rotary vibrating screen sieve vibro spice seed sifter machine

-

Keyword:

-

Rotary vibrating screen classifier

-

Feature:

-

High Screening Efficiency

-

Function:

-

Sieving, grading, removing impurities

-

Material:

-

Stainless Steel 304/316L

-

Advantage:

-

Long Working Life

-

Usage:

-

Fine Particles Screening

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball / Brush / ultrasonic cleaning system

-

Surface Treatment:

-

Mirror Polishing

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZW

-

Voltage:

-

220V/380V/450V/as your requirement

-

Dimension(L*W*H):

-

900*900*930mm

-

Weight:

-

180 KG

-

Product name:

-

Rotary vibrating screen sieve vibro spice seed sifter machine

-

Keyword:

-

Rotary vibrating screen classifier

-

Feature:

-

High Screening Efficiency

-

Function:

-

Sieving, grading, removing impurities

-

Material:

-

Stainless Steel 304/316L

-

Advantage:

-

Long Working Life

-

Usage:

-

Fine Particles Screening

-

Layer(s):

-

1-5 Layers

-

Cleaning system:

-

Bouncing Ball / Brush / ultrasonic cleaning system

-

Surface Treatment:

-

Mirror Polishing

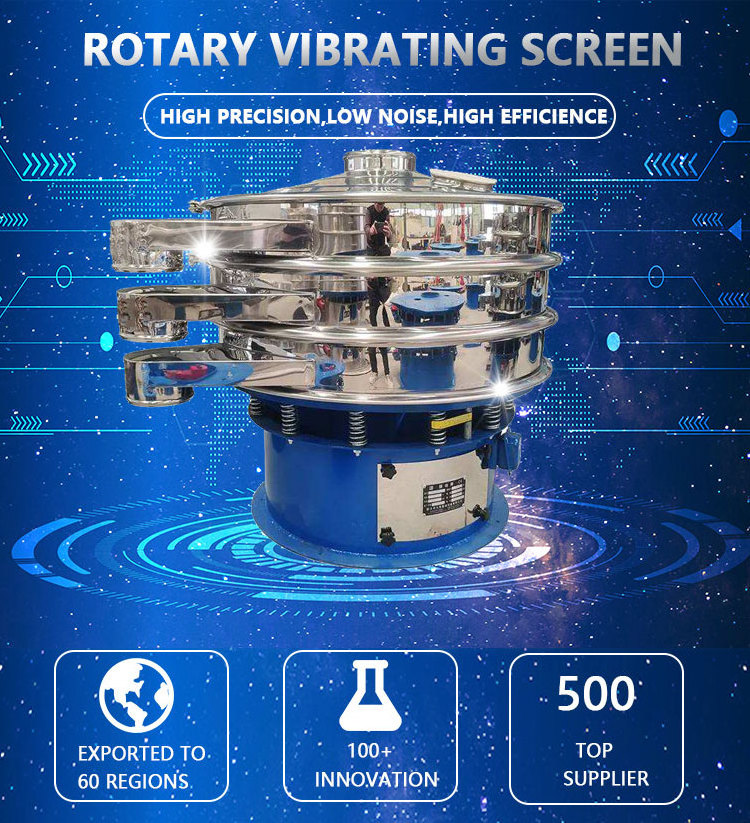

Fine Screening Machine - Rotary Vibrating Screen

Rotary vibration screen is a high precision fine powder screening machine. The working principle of vibrating screen is that the unbalanced weight dropper installed on the top and bottom ends of motor to change the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removing impurities.

Rotary vibration screen is a high precision fine powder screening machine. The working principle of vibrating screen is that the unbalanced weight dropper installed on the top and bottom ends of motor to change the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removing impurities.

Working Principle

Its vertical motor, which is installed with two eccentric hammers on the top and bottom respectively, is regarded as a vibratory source. The eccentric hammers change rotation into horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. Adjusting the phase angle on the top and bottom can change trajectories of the materials on the sieve.

Product Information

-High efficiency, compact and durable design, any powder and mucus can be sieved.

-Easy to change the mesh, simple operation, easy to clean.

-No clogging of mesh, no flying of powder, can be sieved up to 500 mesh or 0.028mm.

-Impurities, coarse material automatically discharged, can be continuous operation.

-Unique design of mesh frame, the screen can be used for a long time, and it takes only 3-5 minutes to change the mesh.

-Small volume, does not occupy space, easy to move.

-The sifter can reach up to five layers, three layers are recommended.

-Easy to change the mesh, simple operation, easy to clean.

-No clogging of mesh, no flying of powder, can be sieved up to 500 mesh or 0.028mm.

-Impurities, coarse material automatically discharged, can be continuous operation.

-Unique design of mesh frame, the screen can be used for a long time, and it takes only 3-5 minutes to change the mesh.

-Small volume, does not occupy space, easy to move.

-The sifter can reach up to five layers, three layers are recommended.

Wide range of screening

Ternary rotary vibration sieve screening: any particles, powder, mucus within a certain range can be screened. The finest screening to 500 mesh or 0.028mm, filtration can be as small as 5 microns. Classification screening, can screen one to five layers of screen mesh, can simultaneously carry out two to six levels of sorting or filtration.

Ternary rotary vibration sieve screening: any particles, powder, mucus within a certain range can be screened. The finest screening to 500 mesh or 0.028mm, filtration can be as small as 5 microns. Classification screening, can screen one to five layers of screen mesh, can simultaneously carry out two to six levels of sorting or filtration.

High efficiency and precise screening

Totally closed structure, no flying powder, no leakage of liquid, no clogging of mesh, automatic discharge, no material storage in the machine, no dead angle of the mesh frame structure, increased screen area.

Totally closed structure, no flying powder, no leakage of liquid, no clogging of mesh, automatic discharge, no material storage in the machine, no dead angle of the mesh frame structure, increased screen area.

Features and Advantages

Sub-mother type, stamping type mesh frame design, 3-5 minutes screen replacement can be completed, change the mesh with 2 people can, the whole machine, screen life is long, less energy consumption, low maintenance costs. Ternary rotary vibration sieve vibration source produces three-dimensional vibration, strong and smooth, the equipment can be installed to any desired location and easy to move.

Sub-mother type, stamping type mesh frame design, 3-5 minutes screen replacement can be completed, change the mesh with 2 people can, the whole machine, screen life is long, less energy consumption, low maintenance costs. Ternary rotary vibration sieve vibration source produces three-dimensional vibration, strong and smooth, the equipment can be installed to any desired location and easy to move.

|

Main technical parameters

|

|

|

|

|||

|

Model

|

Power

(kw)

|

Valid Diameter

of screen

(mm)

|

Volume

(mm)

|

Layers

|

|

ZW-600-1S

ZW-600-2S

ZW-600-3S

|

0.55kw

|

550mm

|

800*800*680

800*800*780

800*800*880

|

1

2

3

|

|

ZW-800-1S

ZW-800-2S

ZW-800-3S

|

0.75kw

|

750mm

|

900*900*780

900*900*930

900*900*1080

|

1

2

3

|

|

ZW-1000-1S

ZW-1000-2S

ZW-1000-3S

|

1.1 kw

|

950mm

|

1160*1160*880

1160*1160*1030

1160*1160*1180

|

1

2

3

|

|

ZW-1200-1S

ZW-1200-2S

ZW-1200-3S

|

1.5 kw

|

1150 mm

|

1360*1360*980

1360*1360*1160

1360*1360*1360

|

1

2

3

|

|

ZW-1500-1S

ZW-1500-2S

ZW-1500-3S

|

2.2 kw

|

1450mm

|

1850*1850*1130

1850*1850*1330

1850*1850*1550

|

1

2

3

|

|

ZW-1800-1S

ZW-1800-2S

ZW-1800-3S

|

3 kw

|

1750mm

|

2200*2200*1360

2200*2200*1460

2200*2200*1680

|

1

2

3

|

|

Dimensions

|

|

|

|

|

||||

|

Equipment

Type

|

A

|

B

|

C

|

D

|

E

|

F

|

H

|

I

|

|

ZW-

400

|

330

|

305

|

200

|

400

|

80

|

70

|

320

|

390

|

|

ZW-

600

|

530

|

430

|

250

|

600

|

100

|

70

|

430

|

415

|

|

ZW-

800

|

680

|

580

|

250

|

800

|

125

|

90

|

540

|

415

|

|

ZW-

1000

|

800

|

700

|

250

|

970

|

150

|

100

|

643

|

415

|

|

ZW-

1200

|

985

|

855

|

400

|

1170

|

180

|

120

|

750

|

540

|

|

ZW-

1500

|

1190

|

1050

|

400

|

1470

|

200

|

120

|

930

|

560

|

|

ZW-

1800

|

1540

|

1440

|

400

|

1770

|

200

|

120

|

1025

|

680

|

|

ZW-

2000

|

1800

|

1720

|

600

|

1960

|

200

|

170

|

1260

|

680

|

1.Our company can design and manufacture special type and specification sieve machine according to user's need.

2.The company reserves the right to modify all technical information and dimensions. If the physical object does not conform to the pattern in the text, the physical object should prevail, and the right of interpretation belongs to the company.

Chemical industry: resin, paint, industrial drugs, cosmetics, paint, Chinese medicine powder, etc.

Food industry: sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

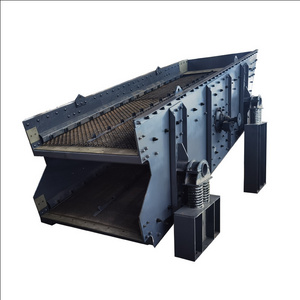

Metals, metallurgy and mining industry: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder,manganese dioxide, electrolytic copper powder, electric Magnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing waste water, auxiliaries, activated carbon, etc.

Food industry: sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

Metals, metallurgy and mining industry: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder,manganese dioxide, electrolytic copper powder, electric Magnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing waste water, auxiliaries, activated carbon, etc.

Xinxiang Zhenwei Screening Machinery Co., Ltd.

is located in the east side of Qinglong Road in Xinxiang economic and technological industrial agglomeration zone, adjacent to 107 National Highway, with superior geographical location and convenient transportation. It is an enterprise committed to the research and development and production of fine screening machinery. It integrates design, production, sales and service, and is committed to solving various screening problems and meeting the requirements of modern construction standards. The introduction of scientific management methods, combined with strong technical force and perfect testing means, has gradually developed into a high-tech enterprise. The company's main products are

swing screen

,

rotary vibrating screen

,

ultrasonic screen

,

air flow screen

and

other fine screening equipment

.

Products are widely used in

food industry

,

chemical synthesis industry

,

plastic industry

,

resin industry

,

Chinese and Western medicine

,

metal powder

,

mining industry

and other industries that need to use screening equipment.

Q1: Industry application

A:Our vibrating screen machines are widely used in food, medicine,chemical industry, metallurgy,mining, ceramics, plastics,electro-magnetic materials, thermoelectricity, building materials and other industries.

A:Our vibrating screen machines are widely used in food, medicine,chemical industry, metallurgy,mining, ceramics, plastics,electro-magnetic materials, thermoelectricity, building materials and other industries.

Q2: Guaranteed

A:The whole machine is guaranteed for one year, and the core accessories are guaranteed for three months.After receiving the goods,if you have any quality problems, please contact us in time.

A:The whole machine is guaranteed for one year, and the core accessories are guaranteed for three months.After receiving the goods,if you have any quality problems, please contact us in time.

Q3: After-sale service

A: lf there is any installation or test machine problem,provide remote online guidance or on-site service.

A: lf there is any installation or test machine problem,provide remote online guidance or on-site service.

Q4: Shipping Method and Shipping Time

A:1.By air port to port: about 7days depends on port. 2.By sea port to port: about 20-35days.

A:1.By air port to port: about 7days depends on port. 2.By sea port to port: about 20-35days.

Q5: Where is Xinxiang Zhenwei Screening Machinery? ls it possible to visit your factory?

A: Our company is located in Xinxiang City, Henan province, a very famous vibrating screen city in China. The city is near by Zhengzhou Airport, it only take one and half hour from Zhengzhou Airport, welcome to visit our company!

A: Our company is located in Xinxiang City, Henan province, a very famous vibrating screen city in China. The city is near by Zhengzhou Airport, it only take one and half hour from Zhengzhou Airport, welcome to visit our company!

Hot Searches