- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

One Year, One Year

-

Brand Name:

-

Golden Bridge

-

Model Number:

-

JQT-2200-C

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

2.2Kw

-

Cable Length:

-

No

-

Outlet Size:

-

No

-

Power:

-

standard

-

motor:

-

2.2Kw

-

Product name:

-

JQT-2200C Regenerative Blower Vacuum Air Compressor

-

Certificate:

-

CE

-

Type:

-

Oilless

-

Motor:

-

2.2Kw

-

Feature:

-

High Efficiency

-

Factory:

-

location in Jinan

-

Material:

-

Aluminum

Quick Details

-

Application:

-

Machining, Water Treatment Solutions, Industrial vacuum cleaners, Enhance and maintain the material, Plastics industry, Soil treatment, Packaging industry, Laser printers, Textile industry, Drying outbuildings, Ventilation of sewage treatment plants, Printing and paper industry, Filling system, Industrial pipeline, Dental vacuum equipment, Swimming pool technology /Jacuzzi, Gas analysis, Gas booster, Increases oxygen fishpond, Vacuum package system, CNC Router

-

Pressure:

-

High pressure

-

Voltage:

-

1-phase 220V, 220V

-

Warranty:

-

One Year, One Year

-

Brand Name:

-

Golden Bridge

-

Model Number:

-

JQT-2200-C

-

Place of Origin:

-

Shandong, China

-

Horsepower:

-

2.2Kw

-

Cable Length:

-

No

-

Outlet Size:

-

No

-

Power:

-

standard

-

motor:

-

2.2Kw

-

Product name:

-

JQT-2200C Regenerative Blower Vacuum Air Compressor

-

Certificate:

-

CE

-

Type:

-

Oilless

-

Motor:

-

2.2Kw

-

Feature:

-

High Efficiency

-

Factory:

-

location in Jinan

-

Material:

-

Aluminum

JQT-2200C Regenerative Blower Vacuum Air Compressor

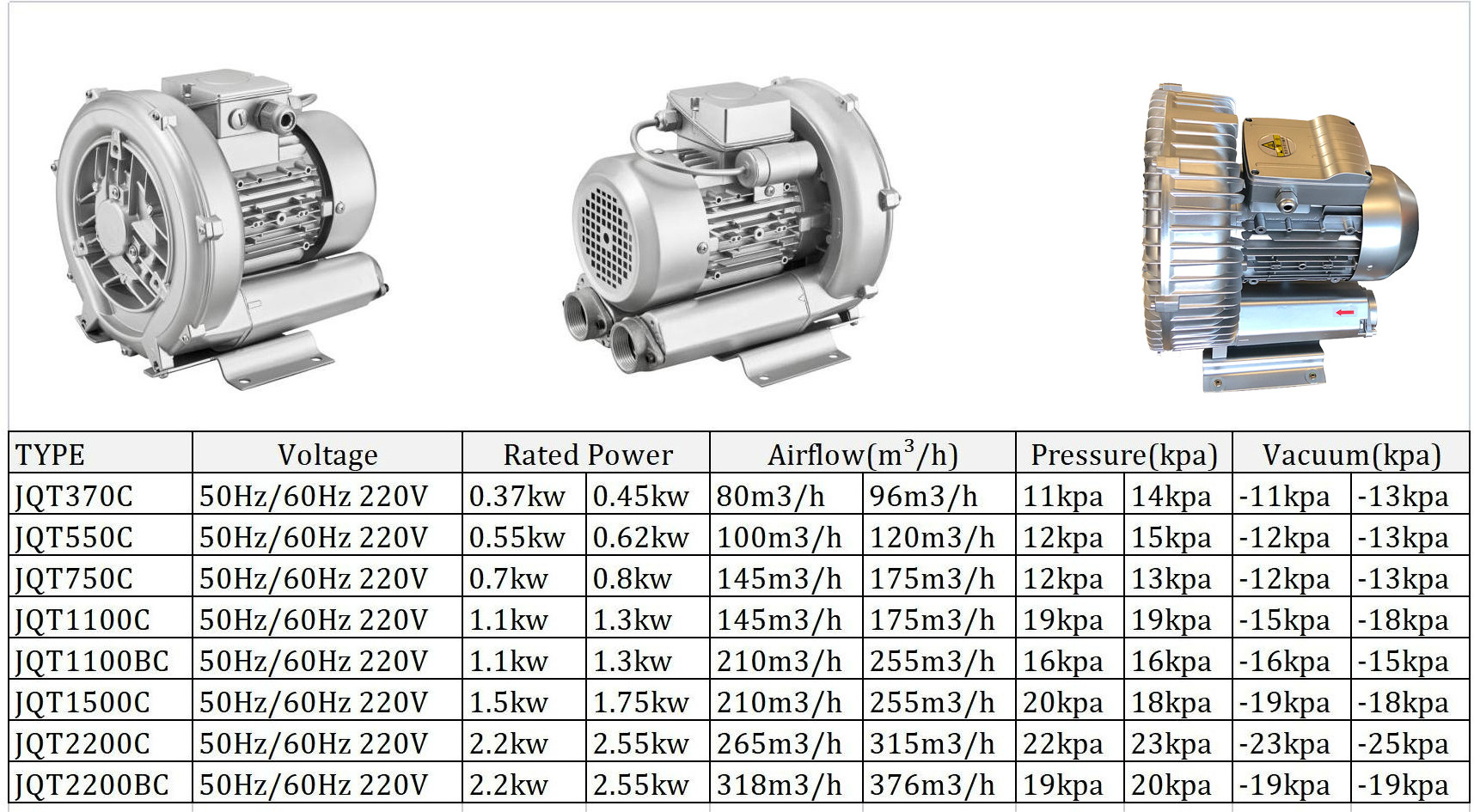

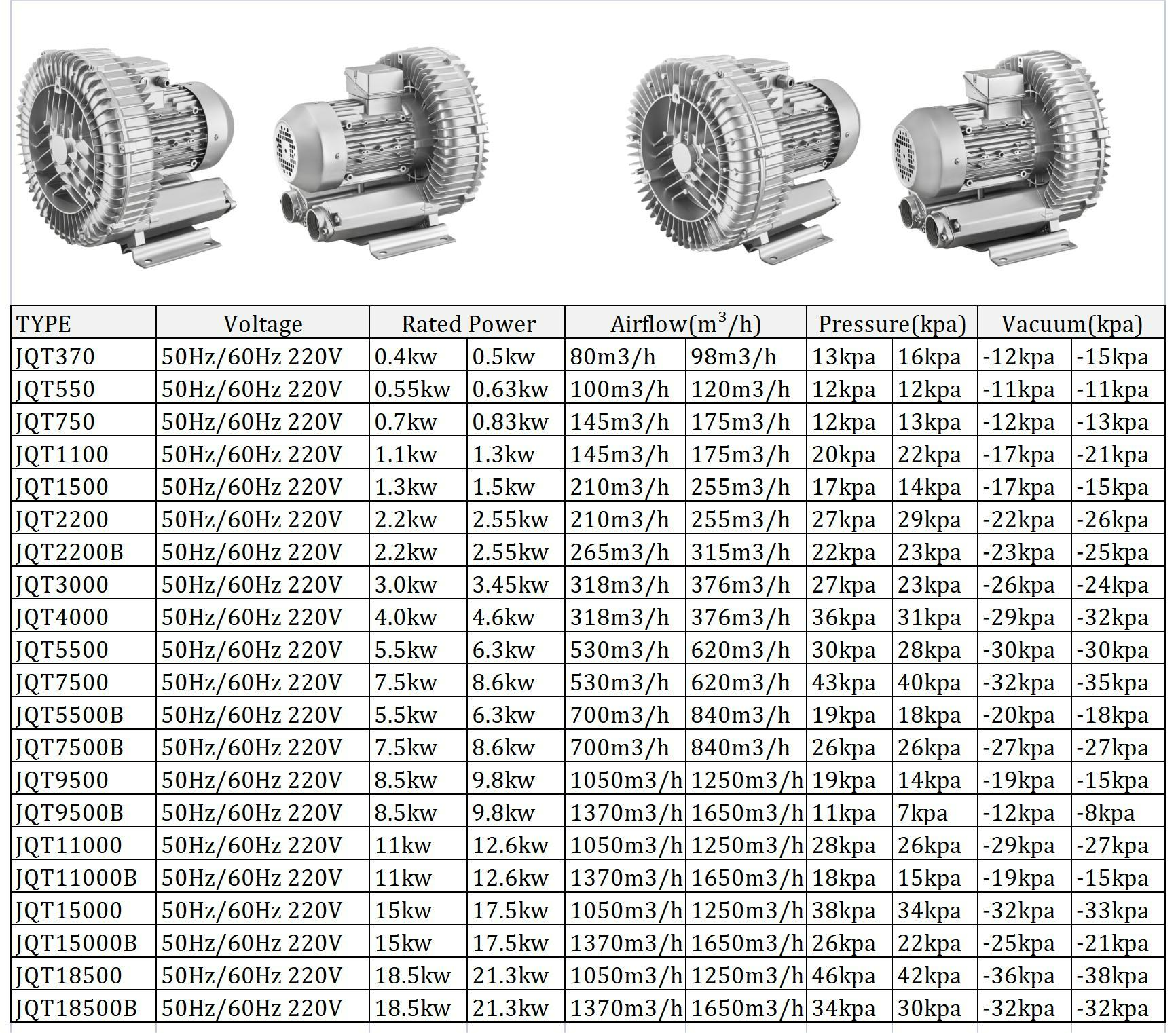

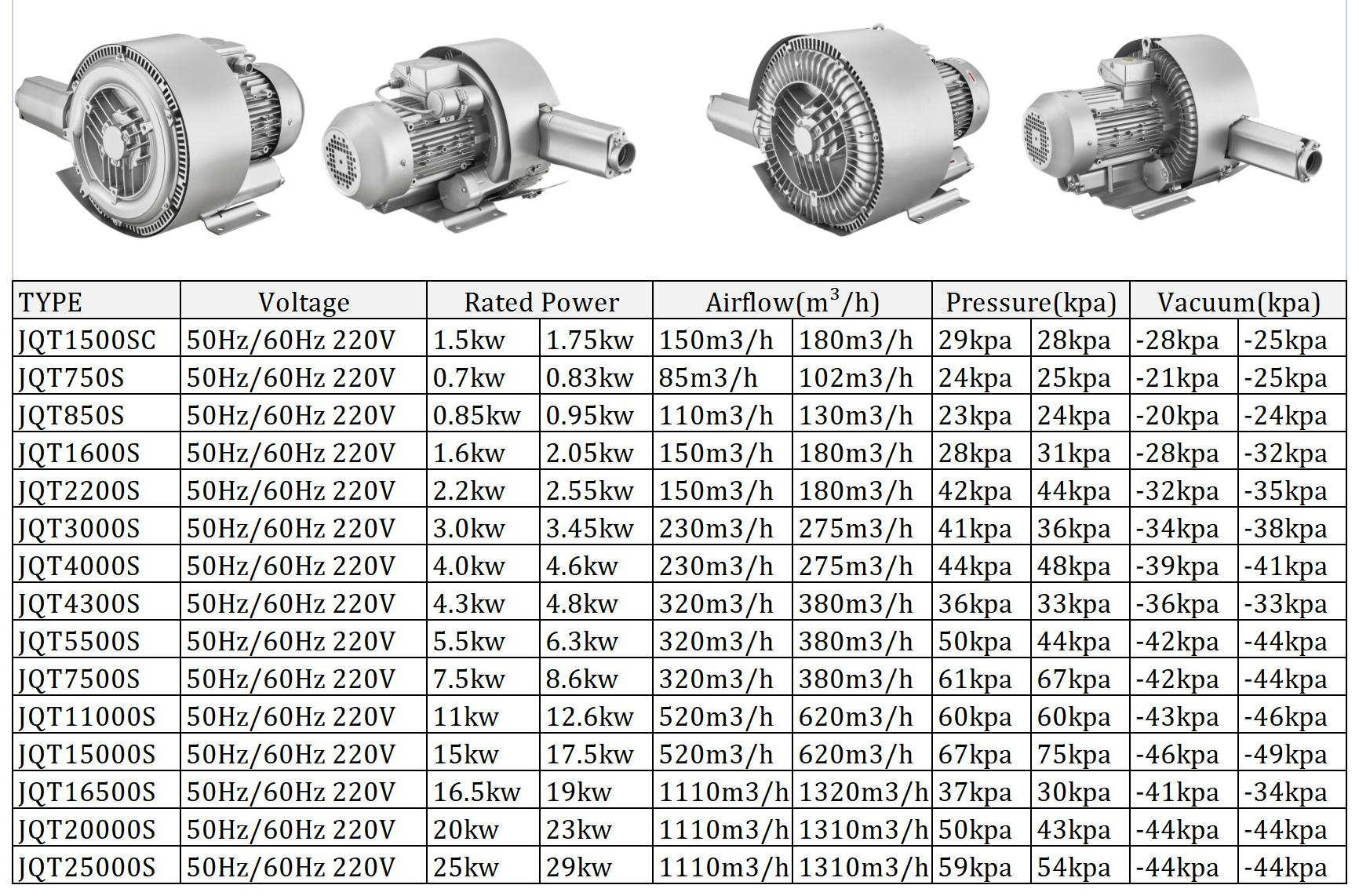

1. Specifications

Single-Phase Side Channel Blower

| Rated Power | Max. Flow | Max. Pressure | Max. Vacuum | ||||

| 370W | 450W | 60m3/h | 76m3/h | 11Kpa | 14Kpa | -11Kpa | -13Kpa |

| 550W | 620W | 95m3/h | 115m3/h | 12Kpa | 15Kpa | -12Kpa | -13Kpa |

| 750W | 830W | 110m3/h | 130m3/h | 12Kpa | 13Kpa | -12Kpa | -13Kpa |

| 1100W | 1300W | 165m3/h | 210m3/h | 19Kpa | 19Kpa | -15Kpa | -18Kpa |

| 1500W | 1750W | 210m3/h | 255m3/h | 20Kpa | 18Kpa | -19Kpa | -18Kpa |

| 2200W | 2550W | 250m3/h | 280m3/h | 19Kpa | 20Kpa | -19Kpa | -19Kpa |

Three-Phase Ring Blower

Double Stage Ring Blower

2. Machine Accessories

Single Stage blower

Double stage blower

3. Blower parts

4. Feature

I. Oil-free

II. Dual-usage

III. Owns low noise

IV. Run constantly for 24hours

V. 50Hz and 60Hz are available.

VI. Maintenance-free.

VII. Easy installation

VIII. Protection class is IP54 and the Insulation class is F.

5. Operation

If the rated current of the motor is exceeded during operation, the voltage and frequency of the power supply should be checked and compared with data on the unit rating plate. Some blowers can’t be operated over the whole range of the performance curve. Overload of the motor may occur due to excessive system back-pressure. In applications where over-pressure conditions may occur, a relief valve must be installed. The ring blower must not be subjected to shock or vibration loads.

6. Maintenance

The ring blower has a non-contact operation and does not normally require maintenance. Wearing parts are subject to the recommended maintenance intervals and are a constituent part of the applicable warranty claims. The service life of bearing parts depends on the operating hours, load, and other Influences such as temperature and operating pressure.

7.Installation

A. Transportation

Check all parts from damage during transport.

B. Installation assembly

The blowers are to be installed weather protected and are not to be stored outdoors unprotected. When the blowers are installed outdoors they must be covered. Install ring blower horizontally or vertically. Do not subject blowers to vibrations or shocks. Blower with base should be secured tightly at the site of operation on solid, even ground. The Ring Compressors can be installed in any direction, but when mounted vertically, the motor side should be upward.

C. Electrical connection

Note! Work described here must be executed by a qualified electrician only. Connect the motor in accordance with the wiring diagram to be found in the terminal box. The blower has a single or three-phase motor as described on the motor plate. The motor should be protected with an overload switch.

D. Control of rotation direction

Startup the blower for a short moment, Check the rotation direction. The rotation direction on the impeller must be in accordance with arrows on the motor. If incorrect rotation is experienced, then check the wiring circuit in the terminal box.