- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QK

-

Dimension(L*W*H):

-

1200*1100*1200mm

-

model:

-

QK-300

-

Motor Power:

-

4kw

-

Reducer:

-

250 type

-

Yield:

-

2-3 ton/h 5000ton/year

-

Overall size:

-

1200*1100*1200mm

-

Packed size:

-

950*850*900mm

-

equipment weight:

-

350KG

-

Origin:

-

Shandong,China

-

Certification:

-

CE

Quick Details

-

Weight (KG):

-

350

-

Marketing Type:

-

New Product 2022

-

Production Capacity:

-

2-3 ton/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QK

-

Dimension(L*W*H):

-

1200*1100*1200mm

-

model:

-

QK-300

-

Motor Power:

-

4kw

-

Reducer:

-

250 type

-

Yield:

-

2-3 ton/h 5000ton/year

-

Overall size:

-

1200*1100*1200mm

-

Packed size:

-

950*850*900mm

-

equipment weight:

-

350KG

-

Origin:

-

Shandong,China

-

Certification:

-

CE

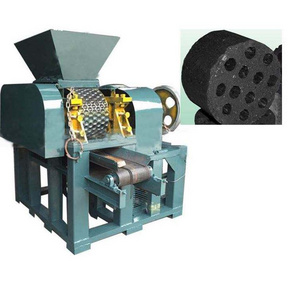

Products Description

The roller skin of ball press is casted with 65 manganese. After special heat treatment, the hardness can reach more than 58 degrees. The roller skins are assembled by combination, which can be replaced after wear and tear. Mineral powder ball press has buffer device, which can better protect the equipment from the impact of hard objects.

The main motor of pellet press: through the V-belt, it is transmitted to the reducer: through the coupling, the reducer is transmitted to the active shaft and then a pair of open gears to ensure the synchronization of the two roller shafts (equal and opposite speed) in which the passive roller is held by the piston of the hydraulic cylinder (constant pressure type is held by the inclined iron), and the hydraulic circuit and hydraulic control valve and accumulator ensure the system pressure, the material is evenly fed into the forming machine hopper from the storage bin through the dosing equipment, and through the adjustment gate on the hopper The material will be adjusted by the adjusting gate on the hopper, so that the material will enter the middle of the rollers evenly, and the unit forming pressure of the material will change from small to large when the rollers are running at the same speed in reverse direction, and the forming pressure will reach the specified value at the center line of the rollers, and after the material passes the line, the forming pressure will become small quickly so that the material will enter the state of deballing and deball smoothly.

Product details

|

Model

|

QK-300

|

|

Motor Power

|

4kw

|

|

Reducer

|

250 type

|

|

Yield

|

2-3 ton/h 5000ton/year

|

|

Overall size

|

1200*1100*1200mm

|

|

Packed size

|

950*850*900mm

|

|

Equipment weight

|

350KG

|

|

Origin

|

China

|

Picture

Packing & Shipping

FAQ

Are you manufacture?

Yes. We are one of leading manufacturers

Do you have Stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual

for punctual delivery.

(2) 20years production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad

situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to

discuss with him for all the problems and the way sames much times.

Our Service

1. 24 hours on line service, support Chinese, English, Spanish, French, German, Russian ,technical guidance.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Provide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Provide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.

Our factory

Jining qingke machinery Co.,Ltd established in July 29,2015. registered capital of 5 million. This is our new branch. Our factory

have has 6 years history. We have CNC machining center.CNC lathe,boring machine and milling machine.

Main products: Steel tube derusting machine , bending machine,. straightening machine, steel arc bending machine, grindingmachine,

garden machine, garden machine, construction machine and road marking machine.

We have passed the ISO9001:2000 certificate. Our products have been exported to Europe, Russia, South America, Australia andMiddle

East, more than 20 countries. We sincerely hope to have the opportunity to co-operate with you

have has 6 years history. We have CNC machining center.CNC lathe,boring machine and milling machine.

Main products: Steel tube derusting machine , bending machine,. straightening machine, steel arc bending machine, grindingmachine,

garden machine, garden machine, construction machine and road marking machine.

We have passed the ISO9001:2000 certificate. Our products have been exported to Europe, Russia, South America, Australia andMiddle

East, more than 20 countries. We sincerely hope to have the opportunity to co-operate with you

Contact

Hot Searches