- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

customized

-

Key Machines:

-

customized

-

Product name:

-

Universal belt quantitative weighing feeder

-

Static metering error:

-

≤0.2%

-

Dynamic cumulative error:

-

≤1%

-

Conveying capacity:

-

1-700(t/h)

-

Belt speed:

-

0 ~ 4m / s

-

Conveying distance:

-

10(m)

-

Control accuracy:

-

better than 0.1%

-

Sensitivity:

-

better than 1%

Quick Details

-

Machinery Capacity:

-

customized

-

Brand Name:

-

Yorktech

-

Weight:

-

600 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

customized

-

Key Machines:

-

customized

-

Product name:

-

Universal belt quantitative weighing feeder

-

Static metering error:

-

≤0.2%

-

Dynamic cumulative error:

-

≤1%

-

Conveying capacity:

-

1-700(t/h)

-

Belt speed:

-

0 ~ 4m / s

-

Conveying distance:

-

10(m)

-

Control accuracy:

-

better than 0.1%

-

Sensitivity:

-

better than 1%

Product Description

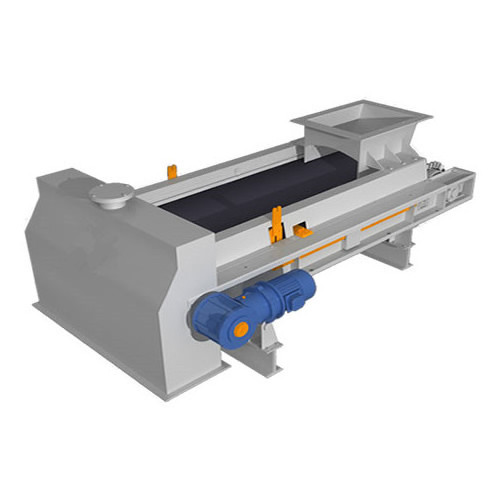

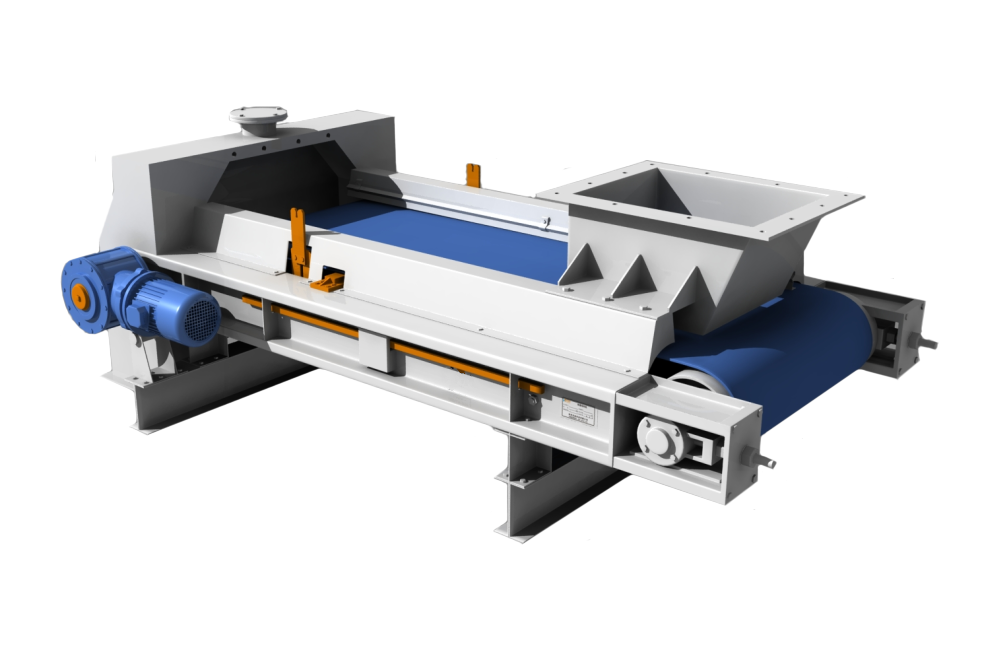

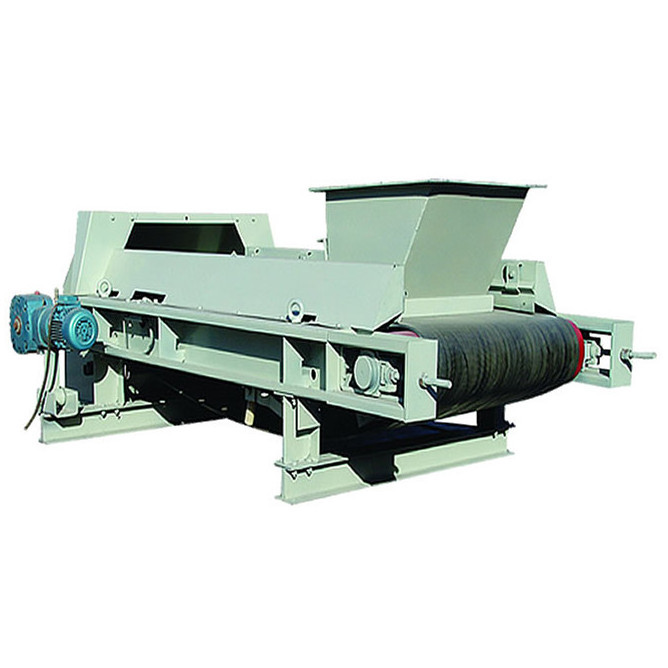

YORK Conveyor Belt Weighing Feeder

YK Conveyor belt weighing feeder is a high-tech product that integrates delivery, weighing and quantitative control, and can adapt to various production environments. For various blocks, granular materials (such as limestone, iron powder, clay) and powder Materials (such as food material, cement) are continuously fed and metered to provide accurate measurement data for production control and management at various industrial sites. They can be used in cement, metallurgy, chemical, food,industry, grain, building materials and other industries.

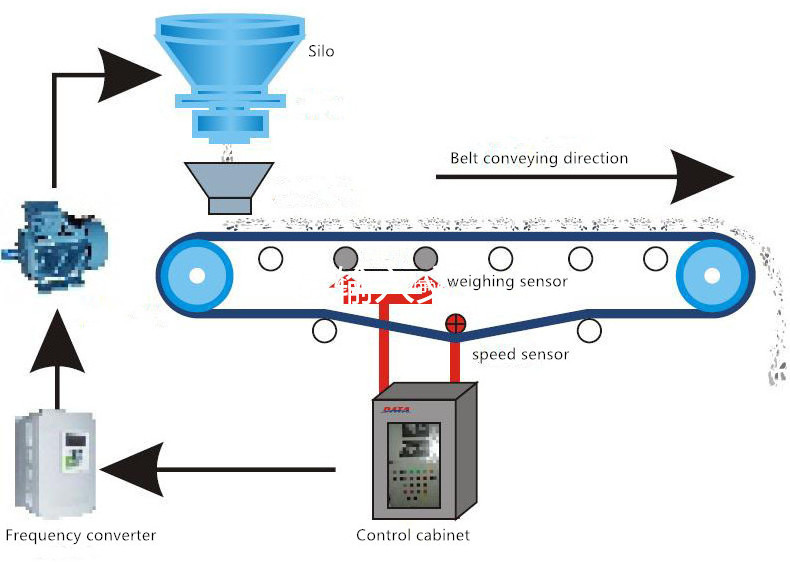

Working principle of belt scale

The weighing bridge is generally installed on the conveyor frame, and the material generally acts on the idler. Through the

lever principle, we transfer the weight of the idler to the weighing sensor, which generates a voltage signal proportional to the weight of the material;

Then the speed sensor is directly connected to the large-diameter speed measuring drum. When the drum drives the belt to rotate,the speed measuring sensor will generate a series of pulse signals proportional to the speed, which will be transmitted to theinstrument,

lever principle, we transfer the weight of the idler to the weighing sensor, which generates a voltage signal proportional to the weight of the material;

Then the speed sensor is directly connected to the large-diameter speed measuring drum. When the drum drives the belt to rotate,the speed measuring sensor will generate a series of pulse signals proportional to the speed, which will be transmitted to theinstrument,

Through integral calculation, the instantaneous material mass is obtained, and through continuous cumulative calculation, the material mass on the whole belt is obtained, so as to achieve accurate dynamic weighing, and finally displayed on the instrument.

Product Specifications

|

Static metering error

|

≤0.2%

|

|

Dynamic cumulative error

|

≤1%

|

|

Conveying capacity

|

1-700(t/h)

|

|

Conveying distance

|

10(m)

|

|

Control accuracy is better than

|

0.1%

|

|

Sensitivity better than

|

1%

|

Details Images

Customer Feedback

Hot Searches