- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Standard Seaworthy package, SUS304/316

-

Weight:

-

194kg---5230kg

-

Size:

-

1816*750*1040---4600*2250*1960mm

-

Power:

-

0.35kw

-

Weight (KG):

-

3000 kg

-

Product name:

-

Wastewater Treatment Machine Volute Sludge Dewatering Machine

-

Application:

-

industrial and municipal wastewater treatment

-

Discharge sludge cake concentration:

-

<80%

-

Inlet sludge concentration:

-

92%-99.8%

-

Screw rotate speed:

-

2-4 round/min

-

Working principle:

-

screw press, without filter cloth

-

Operation model:

-

automatically

-

Voltage:

-

220V / 380V

-

Certification:

-

ISO9001

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Better

-

Material:

-

Standard Seaworthy package, SUS304/316

-

Weight:

-

194kg---5230kg

-

Size:

-

1816*750*1040---4600*2250*1960mm

-

Power:

-

0.35kw

-

Weight (KG):

-

3000 kg

-

Product name:

-

Wastewater Treatment Machine Volute Sludge Dewatering Machine

-

Application:

-

industrial and municipal wastewater treatment

-

Discharge sludge cake concentration:

-

<80%

-

Inlet sludge concentration:

-

92%-99.8%

-

Screw rotate speed:

-

2-4 round/min

-

Working principle:

-

screw press, without filter cloth

-

Operation model:

-

automatically

-

Voltage:

-

220V / 380V

-

Certification:

-

ISO9001

Wastewater Treatment Machine Volute Sludge Dewatering Machine For Sewage Treatment Plant

Product Description

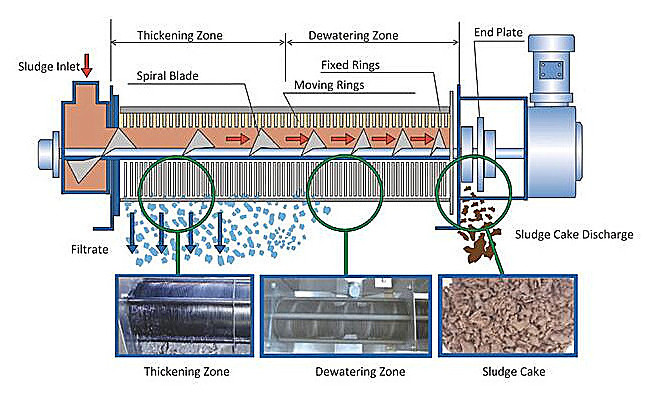

The dewatering main body of the sludge dewatering machine is composed of a condensed section and dewatering section, wherein, the screw shaft runs through the thickening section and the dehydration section. The automatic clear system is equipped with independent, dewatering, swimming ring in pushing the screw shaft, timely cleaning the filter seam, prevent solid blockage in the filtration area; save water for cleaning at the same time, to ensure maximun sustained and stable operation of the equipment.

Features

1. Automatic continuous operation .

2. Compact design with flocculation and dewatering.

3. Low power and water consumption.

4. Low operation cost.

5. No filter cloth, no clogging.

6. No need for sludge thickener.

7. Easy operation and maintenance.

8. No vibration and noise.

Application

Hot Searches