- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/ 220V, 220V/380V

-

Dimension(L*W*H):

-

4500*1850*1550mm

-

Weight:

-

930 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Water consumption:

-

0.7-1 t/h, water can be recyle

-

Feeding Size:

-

0.074mm-2mm

-

Application:

-

placer (gold),tungsten,tin,tantalum,niobium,iron,Mn,coal,tungsten,tin

-

Test:

-

We can supply 6 s shaking table for client's sample testing

-

Deck material:

-

Fiberglass lined with polyurethane and corundum

-

Stroke:

-

16-22mm

-

Installation:

-

Supply you detailed installation Steps in videos, photos and words

Quick Details

-

Production Capacity:

-

1~1.8tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Yongsheng Small Shaking table

-

Voltage:

-

380V/ 220V, 220V/380V

-

Dimension(L*W*H):

-

4500*1850*1550mm

-

Weight:

-

930 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Water consumption:

-

0.7-1 t/h, water can be recyle

-

Feeding Size:

-

0.074mm-2mm

-

Application:

-

placer (gold),tungsten,tin,tantalum,niobium,iron,Mn,coal,tungsten,tin

-

Test:

-

We can supply 6 s shaking table for client's sample testing

-

Deck material:

-

Fiberglass lined with polyurethane and corundum

-

Stroke:

-

16-22mm

-

Installation:

-

Supply you detailed installation Steps in videos, photos and words

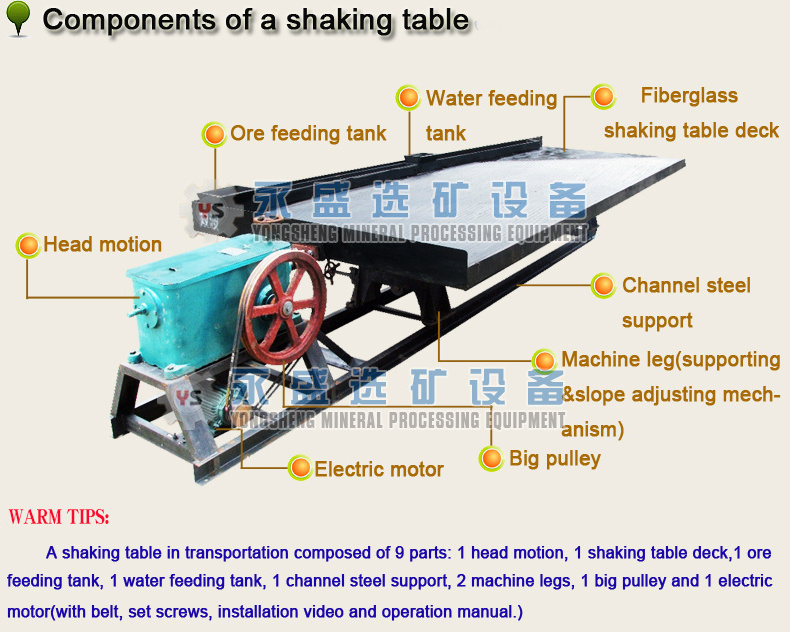

Jiangxi Shicheng 6-S Small mini Gold lab shaker table, Small Shaking Table gold vibration table mineral processing Machine

Introduction

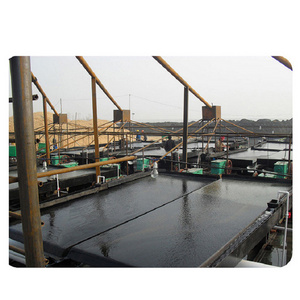

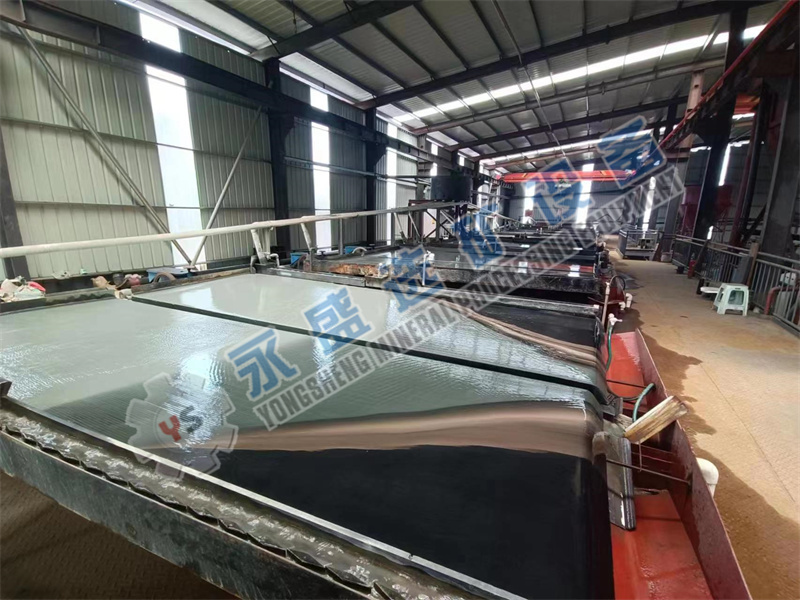

6 s Shaking table is one of the main equipments of gravity concentration. Gravity gold 6 s shaking table is not only widely applied on separating tungsten, the tin, the tantalum niobium and other rare metals and the noble metal ore. Also widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The shaker effective recycling granularity scope is 2-0.037 millimeters.

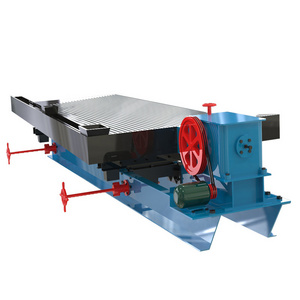

Working principle:

The working principle of 6 s Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fine shaped zoning. Then different products can be produced.

Operation:

Put the raw materials into the feeding launder, and put some water in to make it into slurry of concentration of 20% to 25%, and gravity flow to the deck. The particle group become loose and layered because of the rinsing of water and shaking of the deck in the bed ditch. After the layered, the upper particle and the bottom particle move in different direction because of the different pressure of flowing water and the friction of the bed surface. The upper light particle moves downward along the transverse of bed surface result of the stronger flowing water., this side called tailing side. The heavy mineral particles which located in the bottom of bed layer was influenced by differential movement of bed surface, thus them move to the opposite of the drive end, and we call this point concentrate side. Because of the different density, granularity, and the directions of movement, the groups of mineral particles spread in Fan-shaped along the diagonal of the feeding launder. The production discharge along the edge of bed surface, the discharge line is so long, so that 6 s shaking table could produce many kinds of different quality product precisely.

|

Model

|

Stroke (mm)

|

Cross Slope (°)

|

Feed size (mm)

|

Feed Density (%)

|

Water Consumption (t/h)

|

Capacity (t/h)

|

Power (KW)

|

Weight (KG)

|

|

6S-4450*1855*1546

|

8-22

|

1-4

|

2-0.074

|

15-30

|

0.4-1

|

0.6-1.8

|

1.1

|

800

|

|

LY-3000*1620*1360

|

6-30

|

0-10

|

2-0.074

|

10-30

|

0.3-1.5

|

0.4-1.5

|

1.1

|

550

|

|

LY-2100*1050*850

|

12-28

|

0-8

|

2-0.074

|

10-30

|

0.2-1

|

0.3-0.8

|

1.1

|

350

|

|

LY-1100*500*430

|

9-17

|

0-10

|

2-0.074

|

10-30

|

0.1-0.5

|

0.05-0.2

|

0.55

|

150

|