- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DALON

-

Model Number:

-

BBZ060904

-

Bearing Type:

-

Plain

-

Inside Diameter:

-

06

-

ID Tolerance Range:

-

F7

-

Outside Diameter:

-

09

-

OD Tolerance Range:

-

r7

-

Length:

-

04

-

Length Tolerance:

-

js13

-

For Load Direction:

-

Radial, Thrust, Combined Radial and Thrust

-

Shaft Mount Type:

-

Press Fit

-

Lubrication:

-

Lubricated

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

-

Type:

-

sleeve

-

Material:

-

CuSn663 or SAE841 Bronze

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DALON

-

Model Number:

-

BBZ060904

-

Bearing Type:

-

Plain

-

Inside Diameter:

-

06

-

ID Tolerance Range:

-

F7

-

Outside Diameter:

-

09

-

OD Tolerance Range:

-

r7

-

Length:

-

04

-

Length Tolerance:

-

js13

-

For Load Direction:

-

Radial, Thrust, Combined Radial and Thrust

-

Shaft Mount Type:

-

Press Fit

-

Lubrication:

-

Lubricated

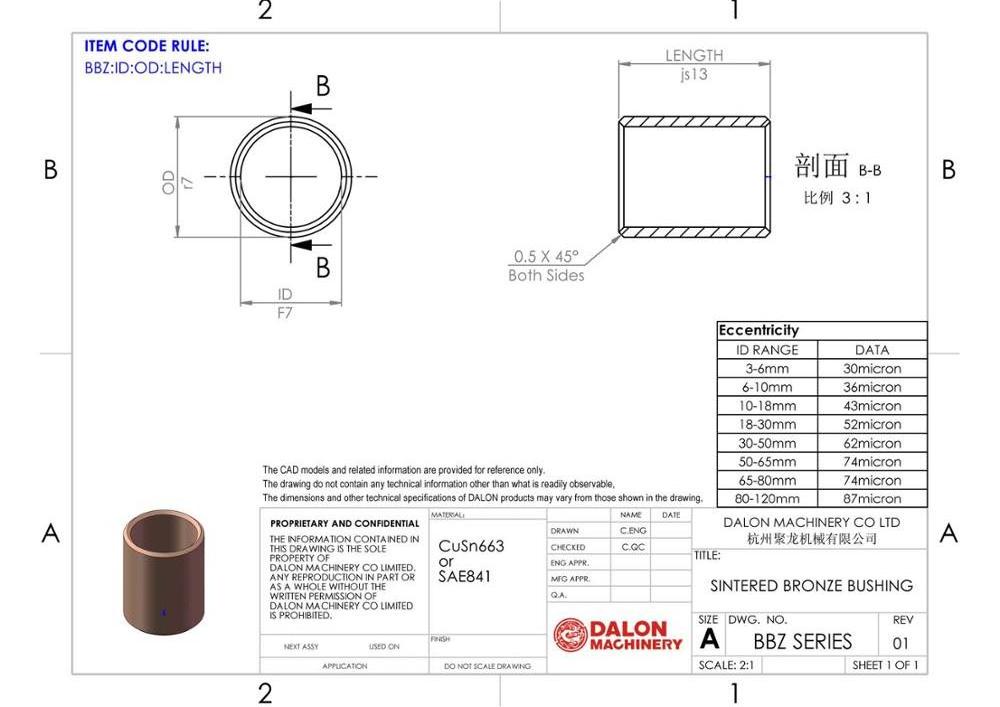

Sintered Powder Metallurgy Bushing with Oil impregnated

|

Bearing Type |

Plain |

|

Plain Bearing Type |

Flanged |

|

Item No. |

BBZ060904 |

|

ID |

06 |

|

ID Tolerance |

F 7 |

|

OD |

09 |

|

OD Tolerance |

r 7 |

|

Length |

04 |

|

Length Tolerance |

Js13 |

|

Material |

CuSn663 or SAE 841 Bronze ; |

|

Dynamic Load Capacity |

15 lbs. @ 2,000 rpm |

|

For Load Direction |

Radial, Thrust, Combined Radial and Thrust |

|

Shaft Mount Type |

Press Fit |

|

Lubrication |

Lubricated |

|

Lubrication Method |

Embedded |

|

Lubricant Type |

Oil |

|

Lubricant |

SAE 30 Oil |

|

Temperature Range |

10° to 220° F |

|

RoHS |

Compliant |

Startup friction causes these porous bronze bearings to release a thin layer of oil on the bearing’s surface. They are also known as Porous bearings.

Note: Dynamic load capacity is the maximum load a bearing can withstand at a given shaft speed. If the bearing’s load and speed are below the values listed, the bearing should work for your application.

DALON Self-lubricating sintered bearings have some advantages compared to other types of dry sliding bearings:

– Reliability.

The constant oil presence eliminates the risk of seizure, and allows the bearing to work during thousands of hours without wear.

– Economy.

Maintenance-free, no need for lubricants.

– Performance.

Able to work under loads of up to 10 MPa, and speeds up to 2.5 m/s. The maximum working PV is is the range of 2.45 N/mm2•m/s, but can be surpassed in special cases. The dimensional precision is very high (up to IT 5 in diameter), and produces extremely low noise.

The main applications for DALON self-lubricating sintered bearings are:

1. Automotive electrical or mechanical equipment, such as:

– Starters.

– Active driving elements:

Brakes, steering, transmission, shock absorbers, …

– Cooling:

Radiator, fans, cooling systems, ….

– EGR systems.

– Fuel pumps.

– Comfort and Security:

Wipers, window regulation, mirrors, seats, sunroofs, …

2. Universal or customized electric motors and gearboxes of medium-low power.

3. Linear and rotary actuators, pneumatic, hydraulic and electromagnetic.

4. Household appliances: Washing machines, fans, extractor fans, shaving machines, depilators, juicers, rostisserie, air conditioning, handtools, coffee machines, wishking machines, vacuum cleaners, lawnmowers, boilers, etc.

5. Home appliances: Locks, garage doors, awnings, roller shutters, sliding windows, office swivel chairs, trolley rolling wheels, hinges, furnitures, gardening, etc.

6. Industrial: Bottling machinery, carpenter machinery, assembly machinery in general, automation, key duplicating machines, sewing machines, industrial vehicles, electrical switchgears, mobility, medical, catering, farm machinery, toys, etc.

DALON ALSO COULD OFFER SERIES OF POWDER METALLURGY PRODUCTS AS ABOVE

- INSERTING TYPE MUFFLER PNEUMATIC AIR SILENCER

- SINTERED POWDER METALLURGY FILTER BY MATERIAL BRONZE / STAINLESS STEEL /PE

- OILLESS SLIDING BEARING WITH SINTERED BRONZE LAYER / PTFE

- SINTERED PARTS / GEARS / ROTORS / SPEICAL DESIGNED COMPONENTS

The manufacturing process of sintered components is certified as ecological, because the material waste is very low, the product is recyclable, and the energy efficiency is good because the material is not molten.

1.RAW MATERIAL / MIXING

Sinter powders can be of pure metal (iron, copper), or alloyed powders (bronze, steel, etc.)mixed with different alloying elements, depending on the composition of the final material (such as graphite, nickel, copper,…), with an organic solid lubricant.

2.TOOLING/COMPACTING

The powder mixture is compacted inside the tooling, which has the negative shape of the final part. The tool is an element of a very high precision, and high durability. The powder is filled into the tool cavity of a mixer by gravity, and pressure within 200 to 1500 MPa is applied onto it depending on the final density to be achieved.

3.SINTERING/INSPECTION

Sintering in continuous furnaces, under controlled speed and at an atmosphere with controlled chemical composition by temperatures between 750 and 1300°C depending on the material

The result of these basic operation is a metallic part with a certain micro-porosity, high dimensional precision, and perfectly functional.

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% before delivery or against copy of shipping B/L. For long term business relations, we have more advantage terms for payment.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5-1: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.