Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

34.7 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

220-440v

-

Dimension(L*W*H):

-

4300x1600x2500mm

-

Power (kW):

-

110

-

Weight:

-

18000 KG

-

Raw material:

-

PVC Powder

-

Processing Type:

-

Exturding Machine

-

Contactor:

-

Schneider Brand

-

Cooling way:

-

Air Cooling

-

Gear box:

-

Jiangyin

-

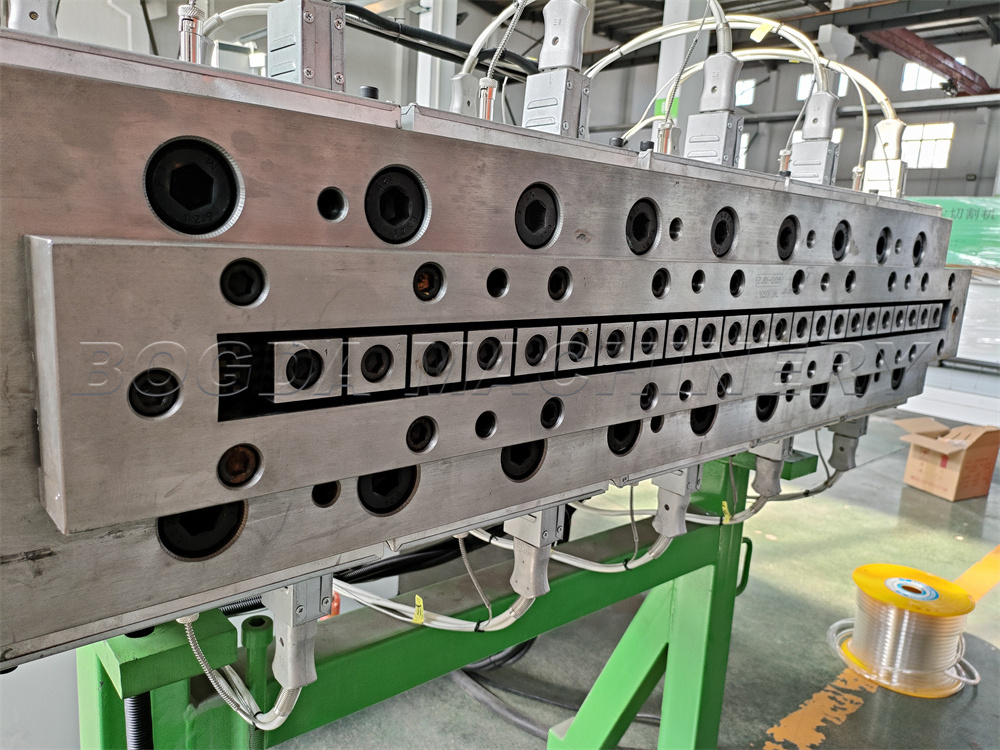

Screw&barrel:

-

38CroMoAlA

-

Control system:

-

Seimens PLC+Touch Screen

-

Door Width:

-

700-1000mm

-

Motor brand:

-

Beide Siemens

-

Scope of application:

-

WPC door

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

25:1

-

Screw diameter (mm):

-

92 188mm

-

Screw Speed (rpm):

-

34.7 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BOGDA

-

Voltage:

-

220-440v

-

Dimension(L*W*H):

-

4300x1600x2500mm

-

Power (kW):

-

110

-

Weight:

-

18000 KG

-

Raw material:

-

PVC Powder

-

Processing Type:

-

Exturding Machine

-

Contactor:

-

Schneider Brand

-

Cooling way:

-

Air Cooling

-

Gear box:

-

Jiangyin

-

Screw&barrel:

-

38CroMoAlA

-

Control system:

-

Seimens PLC+Touch Screen

-

Door Width:

-

700-1000mm

-

Motor brand:

-

Beide Siemens

-

Scope of application:

-

WPC door

Why Choose BOGDA?

1. Bogda uses internationally renowned brand motors and appliances for customers to buy locally.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

2. Bogda can do plant planning for customers and maximize benefits with minimal cost.

3. Bogda adopts special screw, long life, high plasticization.

4. Bogda machinery high degree of automation, low energy consumption, high output.

5. Bogda equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, Bogda will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

Production Application

Product Description

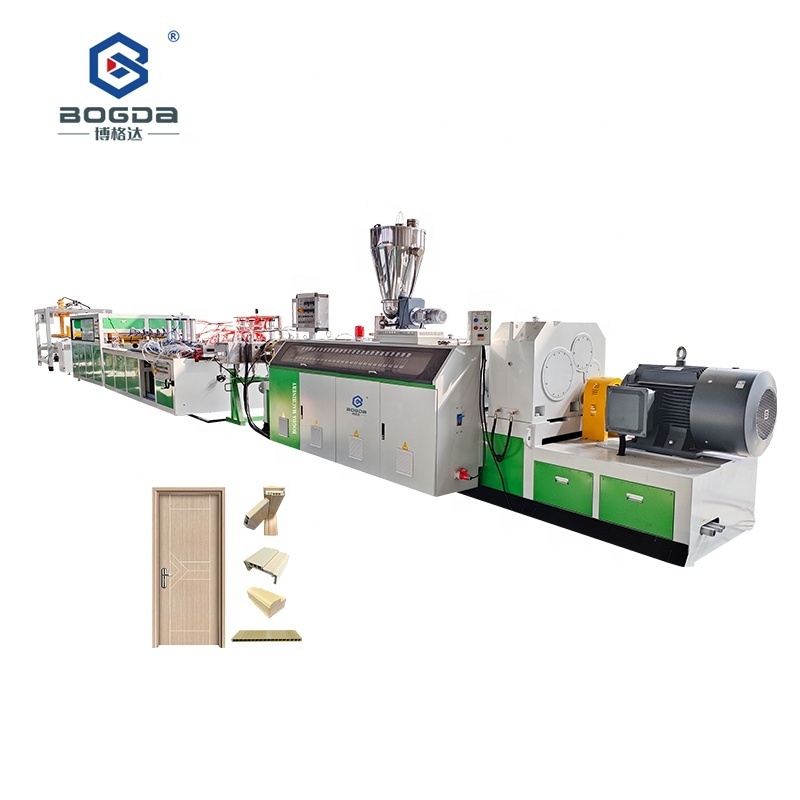

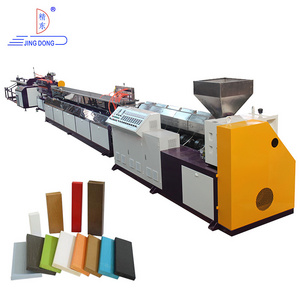

BOGDA Automatic Made In China 1050MM Wide WPC Hollow Door Board Extrusion Machine

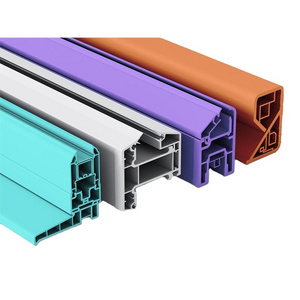

1. Plastic Wood Composite Board Extrusion Line is widely used in production of wpc door, wpc wall panel, garden furniture, etc.

2. Raw material is pvc powder and wood powder, which can be made from waste, recycled wood and pvc products.

3. Plastic wood composite door panel have wood advantages as well as plastic advantages. It features very good hardness and toughness, has the characteristic of secondary processing, can be sawed, planed, bonded, and fixed with nails and screws.

2. Raw material is pvc powder and wood powder, which can be made from waste, recycled wood and pvc products.

3. Plastic wood composite door panel have wood advantages as well as plastic advantages. It features very good hardness and toughness, has the characteristic of secondary processing, can be sawed, planed, bonded, and fixed with nails and screws.

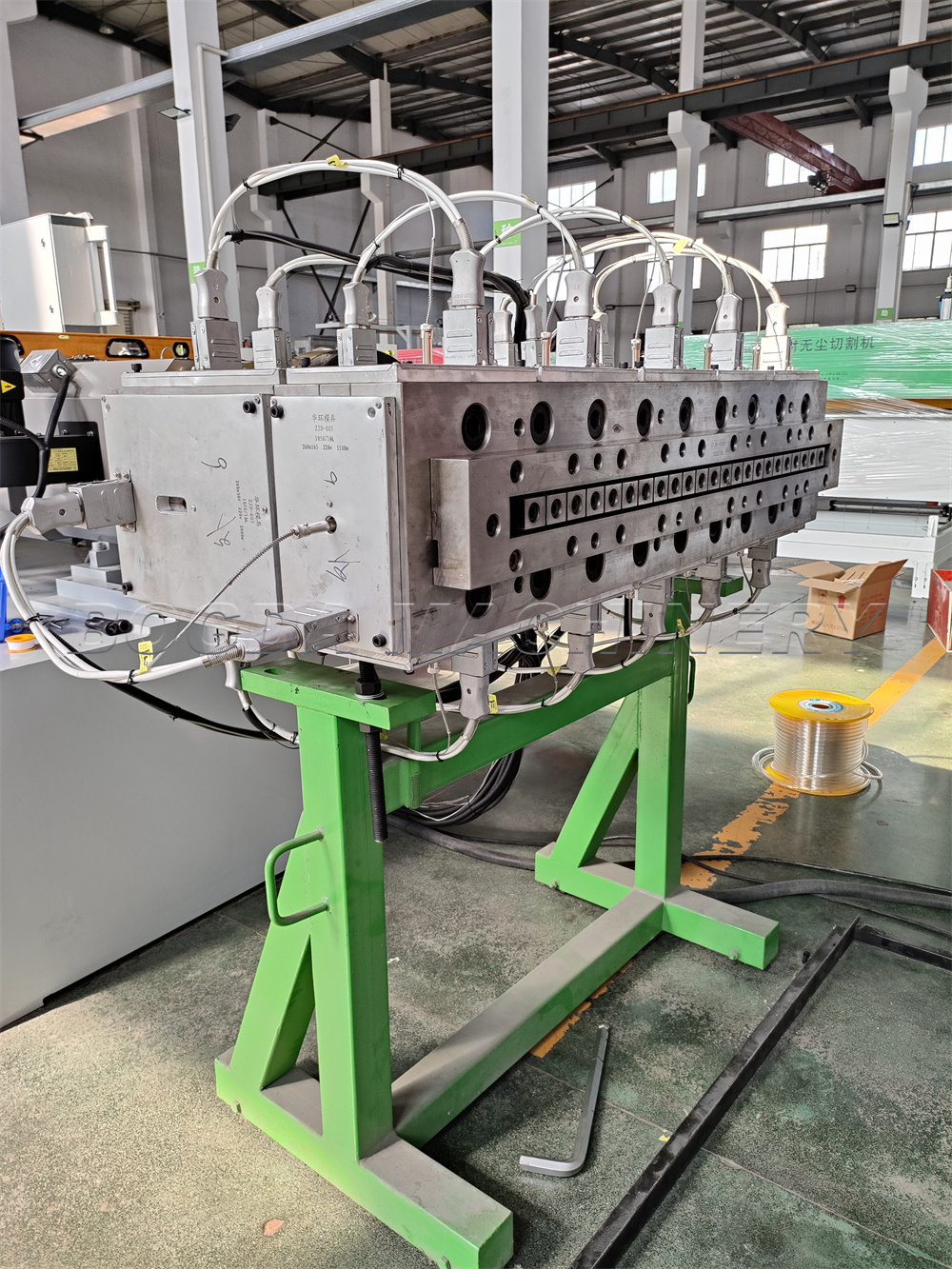

Technical Parameters

|

Model

|

Capacity

|

Product Width

|

Product Thickness

|

|

sjsz92/188

|

600-800kg/hour

|

1050mm

|

40mm

|

Recommend Products

Packing & Delivery

Hot Searches