2.

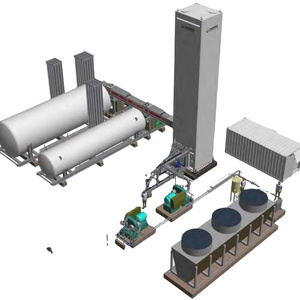

Cryogenic

Air Separation Series Workflow

1.Air compression: The air is compressed by the compressor to 0.8-1.OMpa;

2.Pre-cooling: The air is pre-cooled to 5-10°C in the pre-cooling unit and the moisture is separated;

3.Purification: air is removed from the molecular sieve purifier to remove residual moisture, carbon dioxide 4.and hydrocarbons; air expansion: air is expanded in an expander to cool the unit and provide the required cooling capacity;

5.Heat transfer: The air is heat exchanged with the refluxed oxygen, nitrogen and dirty nitrogen in the fractionator heat exchanger and is cooled close to the liquefaction temperature and the refluxed oxygen, nitrogen and dirty nitrogen is repeatedly heat exchanged to ambient temperature;

6.Subcooling: liquid air and liquid nitrogen before subcooling throttling in a subcooler;

7.Distillation:The air is separated by distillation in the distillation column to obtain the product nitrogen at the top of the upper column and the product oxygen at the bottom of the upper column.