- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

KG

-

Product name:

-

Agitated scraper thin film evaporator for CNSL production

-

Main uses:

-

Industrial Distillationl

-

Name:

-

Short-range Molecular Distillation System

-

Vacuum degree:

-

0.098Mpa

-

Sealing:

-

Mechanical Sealing

-

Application:

-

Food Beverage Chemical Haramceutical Industry

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

VANOO

-

Voltage:

-

customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight:

-

KG

-

Product name:

-

Agitated scraper thin film evaporator for CNSL production

-

Main uses:

-

Industrial Distillationl

-

Name:

-

Short-range Molecular Distillation System

-

Vacuum degree:

-

0.098Mpa

-

Sealing:

-

Mechanical Sealing

-

Application:

-

Food Beverage Chemical Haramceutical Industry

-

After-sales Service Provided:

-

Service Machinery Overseas

Product Overview

Agitated scraper thin film evaporator

Our company has produced and manufactured this kind of equipment for more than ten years, and has accumulated rich manufacturing and use experience. Over the years, according to the market demand, closely combined with the actual production of users, in order to meet the technological requirements of users as the premise, select reasonable and appropriate equipment structure, ensure high-quality and reliable manufacturing quality, and constantly improve and improve the tooling equipment, detection means and product design, etc., and have made remarkable achievements.

SALES AND SERVICE NETWORK

Products Description

This equipment adopts centrifugal sliding grooved rotor, which is a new structure evaporator abroad. It can form thin film in the case of small flow rate. The deposit in the treatment liquid can be quickly removed by the movable scraper. Compared with the fixed gap scraper evaporator, the evaporation capacity can be increased by 40% ~ 69%.

It has the following performance and characteristics:

1. The heat transfer coefficient is high, the evaporation capacity is large, the evaporation intensity can reach 200kg / m2 · HR, and the thermal efficiency is high.

2. The heating time of the material is short, about 5 seconds to 10 seconds, and working under vacuum conditions is more favorable for heat sensitive materials, which can keep all kinds of components from decomposition and ensure the product quality.

It can be applied to a wide range of viscosity (CP).

4. Changing the rotation direction of scraper groove can adjust the material handling time in the evaporator.

5. After precision boring and polishing, the inner wall of evaporation section cylinder is not easy to produce coking and scaling.

6. It is easy to operate and adjust the product index. Under the closed condition, the continuous production can be controlled automatically.

7. The equipment covers a small area, is easy to scale, easy to maintain and clean.

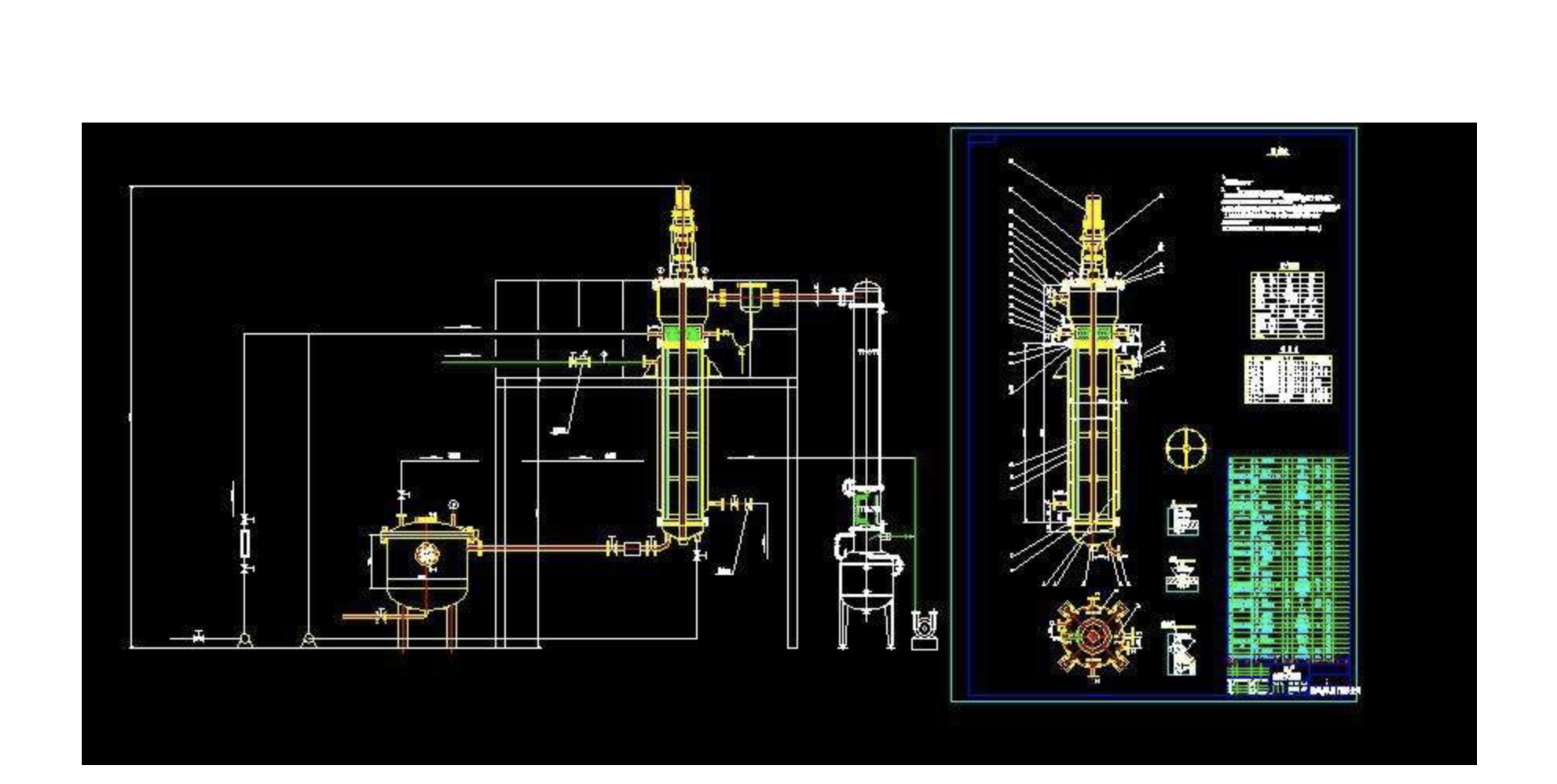

Manufacturing Technique

|

NO.

|

unit

|

GB-0-8

|

GB-1-5

|

GB-2-5

|

GB-4

|

GB-6

|

GB-10

|

|

Heating area

|

m2

|

0.8

|

1.5

|

2.5

|

4

|

6

|

10

|

|

Steam pressure

|

mpa

|

0.3

|

0.3

|

0.3

|

0.3

|

0.3

|

0.3

|

|

Vacuum

|

KP

|

70

|

70

|

70

|

70

|

70

|

70

|

|

Evaporation capacity

|

kg / hr

|

160

|

300

|

500

|

500

|

1200

|

2000

|

|

Energy consumption

|

kg / hr

|

168

|

315

|

525

|

525

|

1260

|

2100

|

|

Motor Power

|

KW

|

1.1

|

1;5

|

2.2

|

2.2

|

5.5

|

11

|

|

Rotary Speed

|

rpm

|

300

|

300

|

280

|

280

|

134

|

88

|

|

Height of machine

|

mm

|

2500

|

3295

|

4100

|

4100

|

5800

|

7800

|

Production process

Machine list

The rotary scraper type film evaporator is mainly composed of motor, reducer, sealing device, separating cylinder, distributor, gas-liquid separator, evaporation cylinder body, rotor, scraper, bottom bearing, discharge barrel, etc

Motor / Reducer

Selecting the appropriate linear speed of the scraper is one of the important parameters to ensure the stable and reliable operation of the evaporator and satisfactory evaporation effect.

Separator

The material enters the evaporator through the inlet of the upper end of the separator barrel, and is continuously and evenly distributed on the inner wall of the evaporation cylinder body through the distributor installed in the separation cylinder body

Distributor

The distributor is mounted on wheels. The reasonable design enables the materials entering the evaporator from the feed inlet to be continuously and evenly distributed on the evaporation surface through the rotating distributor.

separator

The rotary vane gas-liquid separator is installed above the separation cylinder, and it traps and traps the droplets or bubbles that may be carried up by the 2nd time steam.

Evaporator

Double scale heating cylinder body. It is an evaporation surface for heat exchange between the film-forming material forced by the rotary scraper and the heating medium in the jacket. The inner diameter and length of evaporation cylinder body are determined by evaporation area and appropriate length diameter ratio.

Liquid -ring vacuum pump

Provide stable vacuum working environment

Final product shows

Marketing examples

Honey

Cardanol

oil

Waste oil

Fish oil

/

VANOO Machine package

small machine

If the whole machine can be directly loaded into the container, we will put the whole machine into a wooden box. We will remove the important instrument valves in advance and put them into small boxes to ensure that they will not be damaged during long-distance sea transportation

big capacity machine

If it is a large production equipment, we will try our best to protect the equipment, wrap it with cloth and put it into the container

Reasonable use of container space to help customers save freight

Forklift to transport goods into containers

Hot Searches