- Product Details

- {{item.text}}

Quick Details

-

Power:

-

According to equipment

-

Dimension(L*W*H):

-

According to equipment

-

Weight:

-

KG

-

Product Name:

-

10BBL Wine Tank Stainless Steel Fermentation Tank

-

Application:

-

Fermentaion

-

Function:

-

Making wine

-

Capacity:

-

10BBL

-

Keywords:

-

Wine tank

-

Material:

-

SUS304/SUS316/red Copper

-

Heating method:

-

Steam Heating

-

Capacity in BBL:

-

10BBL

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Control system:

-

PLC

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Voltage:

-

Accoring to customer

-

Power:

-

According to equipment

-

Dimension(L*W*H):

-

According to equipment

-

Weight:

-

KG

-

Product Name:

-

10BBL Wine Tank Stainless Steel Fermentation Tank

-

Application:

-

Fermentaion

-

Function:

-

Making wine

-

Capacity:

-

10BBL

-

Keywords:

-

Wine tank

-

Material:

-

SUS304/SUS316/red Copper

-

Heating method:

-

Steam Heating

-

Capacity in BBL:

-

10BBL

-

Thickness:

-

2-3mm / Inside:3.0mm Outside:2mm

-

Control system:

-

PLC

| 10BBL WINE FERMENTATION TANK |

|

| The tank professional for apple, grapes, orange, strawberry, peach processing of berries to generate all kinds of wine and fruit vinegar drink. |

Parameter

|

Model

|

Dimension (mm)

|

Height: (mm)

|

Legs N |

Cooling area (m2) |

|

HG-WF1 |

Φ920*1500 |

2180 |

3 |

1.4 |

|

HG-WF2 |

Φ1270*1610 |

2600 |

3 |

2.2 |

|

HG-WF3 |

Φ1500*1830 |

3000 |

4 |

3 |

|

HG-WF4 |

Φ1600*2000 |

3250 |

4 |

4 |

|

HG-WF5 |

Φ1600*2440 |

3650 |

4 |

5 |

|

HG-WF6 |

Φ1800*2440 |

3500 |

4 |

5.5 |

|

HG-WF8 |

Φ1820*3050 |

4650 |

4 |

7 |

|

HG-WF10 |

Φ1900*3660 |

5050 |

4 |

8.5 |

|

HG-WF12 |

Φ1900*4270 |

5750 |

4 |

10 |

|

HG-WF15 |

Φ2000*4880 |

5950 |

4 |

12 |

|

HG-WF20 |

Φ2300*4880 |

6100 |

4 |

14 |

|

HG-WF25 |

Φ2600*4880 |

6050 |

4 |

15 |

|

HG-WF30 |

Φ2600*5500 |

6550 |

4/6 |

18 |

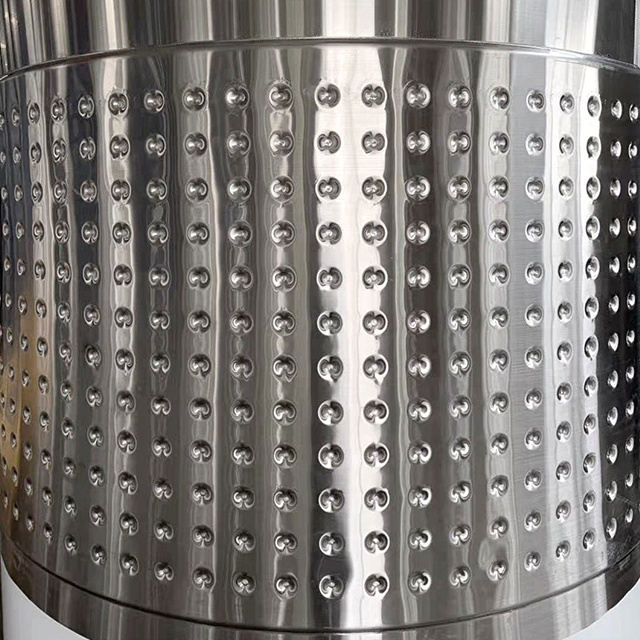

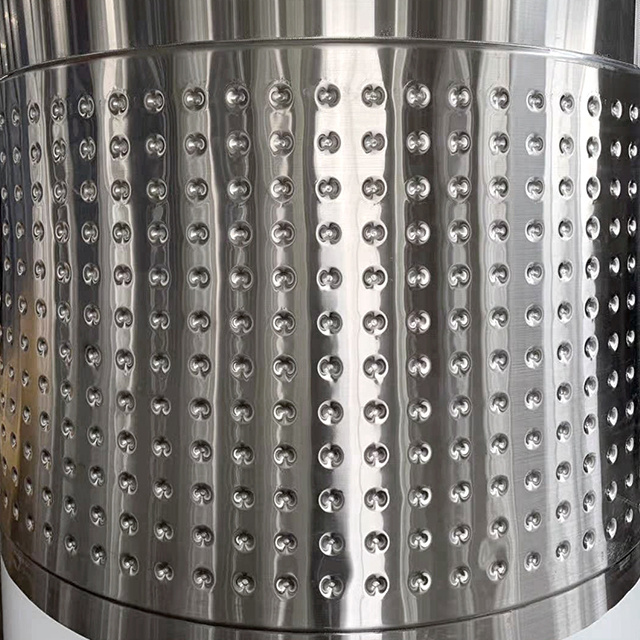

Details about the fermenter

Recommeded By Seller

Send Inquiry>>

Please click to contact us for more information

Processing

About us

Shandong HG Machinery Co., Ltd specializes in providing beer equipment , beverage equipment-based fermentation equipment and fermentation technology. We innovate and endeavour to improve the industrial chain ceaselessly; now we own beer equipment, beverage equipment, bio-pharmaceutical equipment, condiment equipment and other full range of fermentation equipment product lines; thus the company ranks as the backbone of the global fermentation industry. HG locates at Jiyang Zone, Jinan City, covering an area of 18000 square meters. It takes only 18 minutes to the international airport while 15 minutes to the high-speed railway station. The location is superior, and the transportation conditions are convenient for visitors from all over the world.

Certificate

Send Inquiry>>

Please click to contact us for more information

Customer visit

Exhibition

Package delivery

Customer feedback

FAQ

Q:How many years of experience in brewing equipment do you have?

A: We have more than 20 years in brewing and beer filling equipment.

Q: Where is your factory located?

A: Our factory is located in New Town, Jiyang Zone, Jinan, Shandong, China, 2 hours high speed train to Beijing.

Q: How could we confirm the details of the products?

A: We will provide all the drawings for you to confirm before production.

Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries.

Q: How about the installation?

A: We can supply the installation. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

Q: How do you guarantee the filling machine operation?

A: Before the delivery, we will test and debug all machines in good condition and record the video for your checking.