- Product Details

- {{item.text}}

Quick Details

-

Model Item:

-

DW06-350/110X

-

Max height(mm):

-

630

-

Min.Height(mm):

-

400

-

Working Stroke(mm):

-

230

-

Rated working resistance KN:

-

350

-

Weight (Kg):

-

25

-

Rated working Pressure MPa:

-

39.7

-

Setting load KN:

-

132-176

-

Cylinder Dia. (mm):

-

110

Quick Details

-

Weight (KG):

-

110

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Mingda

-

Model Item:

-

DW06-350/110X

-

Max height(mm):

-

630

-

Min.Height(mm):

-

400

-

Working Stroke(mm):

-

230

-

Rated working resistance KN:

-

350

-

Weight (Kg):

-

25

-

Rated working Pressure MPa:

-

39.7

-

Setting load KN:

-

132-176

-

Cylinder Dia. (mm):

-

110

Product Description

Mining Requirements:

hydraulic props are primarily employed in slightly or partly mechanized coal mines, but are also found in ore mines, industrial

mineral mines, etc.Even in fully-mechanized mines hydraulic props are still in use for special support, for example in areas of

geological faults, at the ends of the face, face-roadway intersections, etc. due to their flexibility and versatility.

With conventional props, high pollution of mine water and drainage ways due to use of oil-in-water emulsion for hydraulic fluid.

Glued - joint steel pipe props from Mingko use pure water as hydraulic fluid and thereby contribute to environmental protection.

Lifespan:The long lifespan and suitability for reuse, in conjuction with the capability to replace defective components, ensure

longlasting employment.

OPERATING PRINCIPLE:

Hydraulic props consist of a sealed working cylinder with two valves, one for intake (setting valve) and the other for discharge

(release valve, working valve) of hydraulic fluid. For increased stability the hydraulic props are equipped with a claw at the

upper head-end and a base at the bottom. The function of the props is to stabilize incompetent roof or hanging wall. The

positioned prop is telescopically extended by highly-pressurized hydraulic fluid injected by means of a setting gun and wedged

into place with a specific setting load adjusted according to the respective compressive rock load. When the rated load is reached

during installation or by subsequent strata movement, the working valve engages and opens the cylinder. This yielding prevents

damage to the support from increasing compressive loading. The optimal support is attained when the props are installed in

combination with articulated bars which distribute the forces over a wider hanging-wall or roof surface. During prop recovery, the

release valve is opened with a key, allowing the hydraulic fluid to escape and the prop, equipped with a spring, to recede. The

prop is then available for reuse.

AREAS OF APPLICATION:

Use of hydraulic single prop supports is only practical and economic where incompetent roof or hanging wall require a support

method which can be adjusted to meet rapidly changing conditions. Hydraulic prop supports are appropriate for short-term

installations involving frequent changes of location due to rapid face advance, or where high prop-setting loads are desireable.

Such conditions arise in coal mining with roof caving or backfilling, in longwall mining, in room and pillar mining, as well as in

ore mining by overhand stoping. In addition, single hydraulic props are suitable for support of all special mining activites such

as support of fault-zones or roof-fall areas, machine rooms, and face-roadway

intersections.

REMARKS:

The use of single hydraulic props in the situations listed above can contribute significantly to protecting valuable natural

resources by substituting for traditional timbering methods. Replacing the normally non-reuseable support timbers (e.g. in Turkey,

totalling more than 1 m3/20 t of useable output) with re-usable props can also result in decreased operating costs.

The limited working length of the hydraulic prop, like mechanical friction props, is disadvantageous in mines with fluctuating

seam or vein thickness.Due to the high setting load achievable with hydraulic props, capable of supporting areas 5 to 10 times

larger than mechanical props, the prop density can be reduced.The Company is striving to adapt their products (individual props

and articulated bars) to meet the demands of small-scale mining in developing countries:

- assembly and repair can be performed by local labor. The costs for an assembly and repair shop amount to only around 10 % of the

costs of commonly

manufactured parts.

- the approx. 30 % net product arising from local production preserves the

country's foreign exchange position.

- cost savings of more than 50 % can be realized compared to the widely-used wood timbering.

- the capital investment for a highly developed and complex support system is not required.

- the use of glueable Joints in this modular system permits the replacement of damaged parts, therefore increasing the lifespan of

the remaining components.

- storage costs are reduced by around 70 % as inventory can be limited to only a few standardized parts.Disadvantages of hydraulic

props include high consequential or related costs for producing and distributing high-pressure fluids (pneumatic or electric

high-pressure pump, liquid storage tank, high-pressure hoses, setting guns, etc.).

This disadvantage can be overcome by employing props which are set with manually-operated pumps. Such props were employed earlier

in Germany, and are still used today in Anglo-Saxon countries. They function by using a hand pump to force the hydraulic fluid

from the upper cylinder (storage cylinder)

into the lower cylinder (working cylinder), analogous to a hydraulic automobile jack.

SUITABILITY FOR SMALL-SCALE MINING:

The type of prop system employed affects the consequential costs. Simple manually-operated props offer an alternative to timbering

in small-scale mines. The investment for single hydraulic props with an external pump system can only be recovered when large

quantities are employed to

offset the higher costs for the necessary auxiliary installation devices.

hydraulic props are primarily employed in slightly or partly mechanized coal mines, but are also found in ore mines, industrial

mineral mines, etc.Even in fully-mechanized mines hydraulic props are still in use for special support, for example in areas of

geological faults, at the ends of the face, face-roadway intersections, etc. due to their flexibility and versatility.

With conventional props, high pollution of mine water and drainage ways due to use of oil-in-water emulsion for hydraulic fluid.

Glued - joint steel pipe props from Mingko use pure water as hydraulic fluid and thereby contribute to environmental protection.

Lifespan:The long lifespan and suitability for reuse, in conjuction with the capability to replace defective components, ensure

longlasting employment.

OPERATING PRINCIPLE:

Hydraulic props consist of a sealed working cylinder with two valves, one for intake (setting valve) and the other for discharge

(release valve, working valve) of hydraulic fluid. For increased stability the hydraulic props are equipped with a claw at the

upper head-end and a base at the bottom. The function of the props is to stabilize incompetent roof or hanging wall. The

positioned prop is telescopically extended by highly-pressurized hydraulic fluid injected by means of a setting gun and wedged

into place with a specific setting load adjusted according to the respective compressive rock load. When the rated load is reached

during installation or by subsequent strata movement, the working valve engages and opens the cylinder. This yielding prevents

damage to the support from increasing compressive loading. The optimal support is attained when the props are installed in

combination with articulated bars which distribute the forces over a wider hanging-wall or roof surface. During prop recovery, the

release valve is opened with a key, allowing the hydraulic fluid to escape and the prop, equipped with a spring, to recede. The

prop is then available for reuse.

AREAS OF APPLICATION:

Use of hydraulic single prop supports is only practical and economic where incompetent roof or hanging wall require a support

method which can be adjusted to meet rapidly changing conditions. Hydraulic prop supports are appropriate for short-term

installations involving frequent changes of location due to rapid face advance, or where high prop-setting loads are desireable.

Such conditions arise in coal mining with roof caving or backfilling, in longwall mining, in room and pillar mining, as well as in

ore mining by overhand stoping. In addition, single hydraulic props are suitable for support of all special mining activites such

as support of fault-zones or roof-fall areas, machine rooms, and face-roadway

intersections.

REMARKS:

The use of single hydraulic props in the situations listed above can contribute significantly to protecting valuable natural

resources by substituting for traditional timbering methods. Replacing the normally non-reuseable support timbers (e.g. in Turkey,

totalling more than 1 m3/20 t of useable output) with re-usable props can also result in decreased operating costs.

The limited working length of the hydraulic prop, like mechanical friction props, is disadvantageous in mines with fluctuating

seam or vein thickness.Due to the high setting load achievable with hydraulic props, capable of supporting areas 5 to 10 times

larger than mechanical props, the prop density can be reduced.The Company is striving to adapt their products (individual props

and articulated bars) to meet the demands of small-scale mining in developing countries:

- assembly and repair can be performed by local labor. The costs for an assembly and repair shop amount to only around 10 % of the

costs of commonly

manufactured parts.

- the approx. 30 % net product arising from local production preserves the

country's foreign exchange position.

- cost savings of more than 50 % can be realized compared to the widely-used wood timbering.

- the capital investment for a highly developed and complex support system is not required.

- the use of glueable Joints in this modular system permits the replacement of damaged parts, therefore increasing the lifespan of

the remaining components.

- storage costs are reduced by around 70 % as inventory can be limited to only a few standardized parts.Disadvantages of hydraulic

props include high consequential or related costs for producing and distributing high-pressure fluids (pneumatic or electric

high-pressure pump, liquid storage tank, high-pressure hoses, setting guns, etc.).

This disadvantage can be overcome by employing props which are set with manually-operated pumps. Such props were employed earlier

in Germany, and are still used today in Anglo-Saxon countries. They function by using a hand pump to force the hydraulic fluid

from the upper cylinder (storage cylinder)

into the lower cylinder (working cylinder), analogous to a hydraulic automobile jack.

SUITABILITY FOR SMALL-SCALE MINING:

The type of prop system employed affects the consequential costs. Simple manually-operated props offer an alternative to timbering

in small-scale mines. The investment for single hydraulic props with an external pump system can only be recovered when large

quantities are employed to

offset the higher costs for the necessary auxiliary installation devices.

Specification

|

Model Item

|

Max height(mm)

|

Min.Height(mm)

|

Working Stroke(mm)

|

Rated working resistance KN

|

Weight (Kg)

|

Rated working Pressure MPa

|

Hydraulic pump pressure MPa

|

Setting load KN

|

Cylinder Dia. (mm)

|

|

DW06-350/110X

|

630

|

400

|

230

|

350

|

25

|

39.7

|

15-20

|

132-176

|

110

|

|

DW08-350/110X

|

800

|

490

|

310

|

|

28

|

|

|

|

|

|

DW10-350/110X

|

1000

|

595

|

405

|

|

32

|

|

|

|

|

|

DW12-350/110X

|

1200

|

700

|

500

|

|

36

|

|

|

|

|

|

DW14-350/110X

|

1400

|

810

|

590

|

|

40

|

|

|

|

|

|

DW16-350/110X

|

1600

|

920

|

680

|

|

44

|

|

|

|

|

|

DW18-350/110X

|

1800

|

1035

|

765

|

|

48

|

|

|

|

|

|

DW20-350/110X

|

2000

|

1150

|

850

|

|

52

|

|

|

|

|

|

DW22-350/110X

|

2240

|

1280

|

960

|

|

56

|

|

|

|

|

|

DW25-350/110X

|

2500

|

1430

|

1070

|

|

60

|

|

|

|

|

|

DW28-350/110X

|

2800

|

1600

|

1200

|

|

66

|

|

|

|

|

|

DW31.5-350/110X

|

3150

|

1780

|

1370

|

|

74

|

|

|

|

|

|

DW35-350/110X

|

3500

|

1960

|

1540

|

|

82

|

|

|

|

|

|

DW38-250/110X

|

3800

|

2163

|

1637

|

250

|

88

|

28.3

|

|

|

|

|

DW40-250/110X

|

4000

|

2224

|

1780

|

|

96

|

|

|

|

|

|

DW42-250/110X

|

4200

|

2330

|

1880

|

|

100

|

|

|

|

|

|

DW45-250/110X

|

4500

|

2480

|

2020

|

|

110

|

|

|

|

|

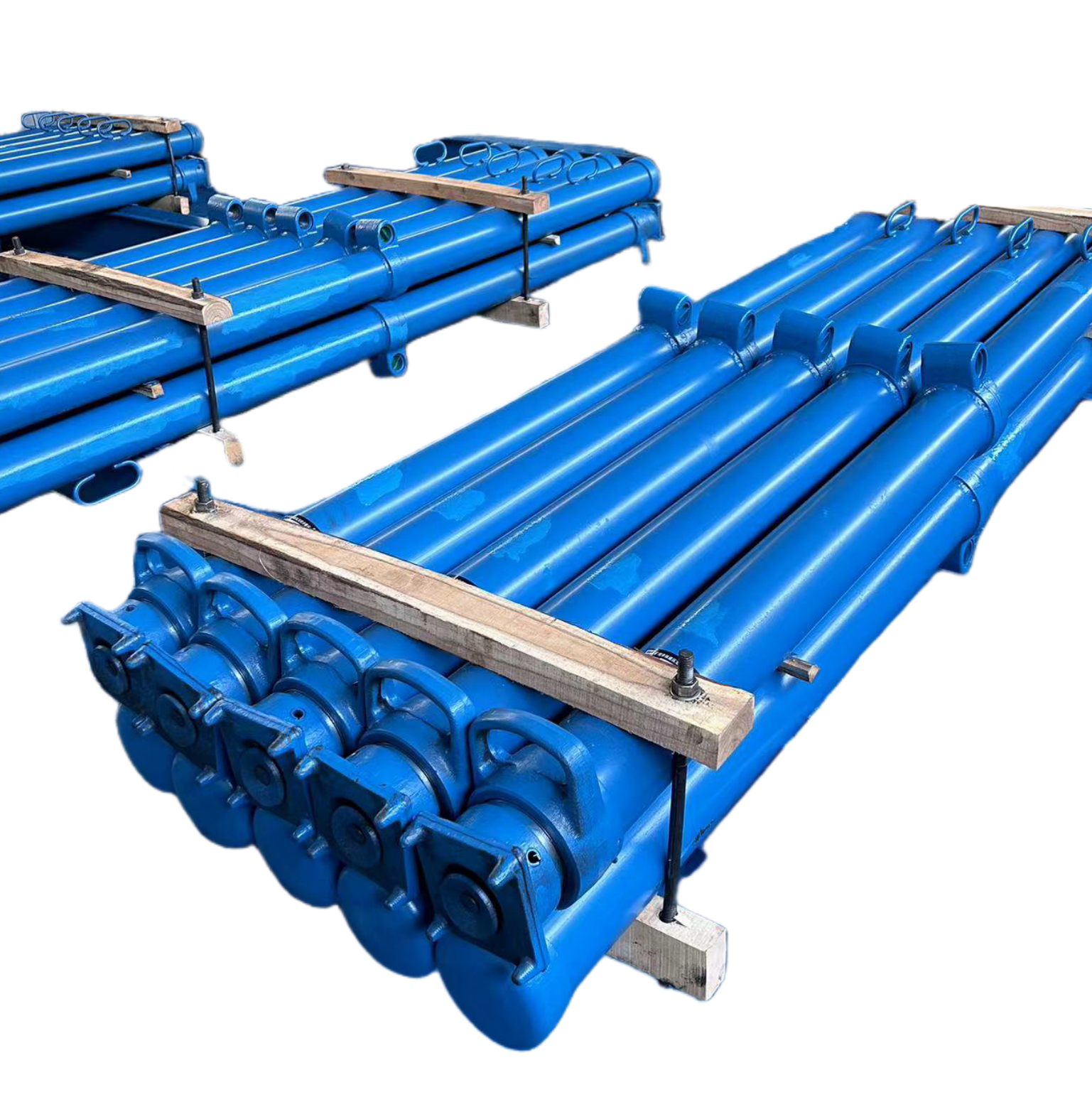

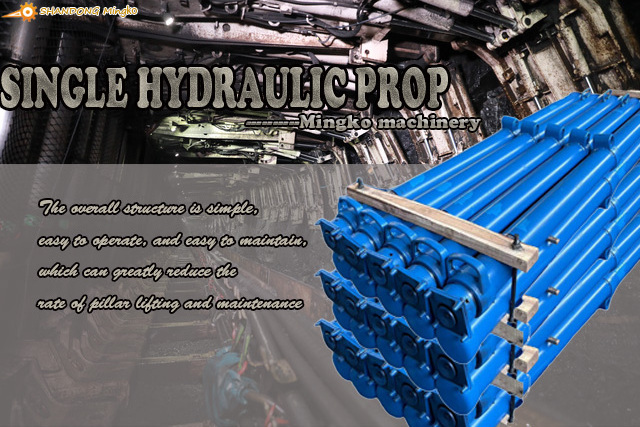

PRODUCT DISPLAY

Application Scenario

Click to Send a Inquiry

Hot Searches